Pond Liner Calculator

In this pond liner calculator article, we answer the following frequently asked questions

1. How is a dam liner calculated?

The formulae adopted depends the shape of the water pan. The water reservoir’s dam liner is calculated differently for a circular or oval water pan vis a vis that of a square/ rectangular one. Similarly, a square water tank has a different formulae from a circular one. A water pan with slanting edges has a different formulae from that with straight edges. Whether the water reservoir or tank is for irrigation, domestic or industrial application, the formulae is the same

I. Square/ rectangular water reservoir or tank pond liner calculator

a. Square/ rectangular pond liner calculator for straight edges: Total length in meters: (length + 2depth + 2meters). Total width in meters: (width + 2depth +2meters). The additional 2meters on each side are for the overlap which is tucked in a trench for water reservoirs. For tanks, it’ll be 0.5M. Multiplying the total length with the total width gives the pond liner area in meters

Pond liner installation in a water reservoir with straight edges

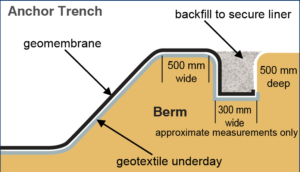

Tucking is in a trench all around the water pan

How to trench and tuck your pond liner

b. Square/ rectangular pond liner calculator for slanted edges: Total length in meters: (base length + 2slanting depth + 2meters). Total width in meters: (base width + 2slanting depth +2meters). Multiplying the total length with the total width gives the pond liner area in meters

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

II. Circular pond liner calculator

Diameter + (2height/ depth) + (1meter). The 1meter is the external allowance that goes outside the tank as shown in the image below

A liner in a cylindrical tank

2. How do I calculate how much pond liner I need?

The size of the pond liner is according to the water pan or water tank area. The size of the water pan or tank is by volume, shown as; length by width by depth/ height. The liner size is by area, shown as; length by width. For this conversion, the formulas shown above work

The larger the water pan or tank, the larger the pond liner required