How To Grow Azolla

When training farmers on how to grow azolla in Kenya using Grekkon Limited’s dam liners, and shade nets, the company offers a detailed session to farmers as documented in this article. Azolla pinnata is the most common variety grown in Kenya

What is Azolla?

Azolla, belonging to the Salvinaceae family is a fresh water aquatic plant. It is a nitrogen fixing, branched free-floating fern also referred to as duckweed, mosquito fern or water fern. Its most popular characteristic is its ability to exponentially grow by doubling its biomass every 3 days depending on the growing conditions. This is why it is regarded as a super plant. Some refer to it as the green gold mine due to its high nutritive value

Azolla growing in troughs made of dam liner material, and under a green shade net – materials supplied by Grekkon Limited

Benefits of azolla

- it is a green manure because of its nitrogen fixing property

- it reduces weeds

- soil organic carbon is increased which in turn microbial biomass in the soil

- as a livestock feed, its is an economical way of providing affrodable high protein, essential amino acids, and vitamins (A, B12, Beta Carotene) to animals

How to grow azolla in Kenya

Nutrition Requirements

i .Light: Azolla grows well under partial shade. Growth decreases quickly under heavy shade (lower than 1,500 lux) and more than 50% of full sunlight reduces photosynthesis. This is why a shade net cover is necessary where sunlight is intense. It causes it to turn reddish brown, which reduces the nutrient value

ii. Nutrition: for vigorous production, add 20kgs per Ha of phosphorous. Cow dung slurry, and super phospahte fertiliser provides this

iii. Relative humidity : high at 80 – 90 %

iv. Growing PH: lightly acidic media at : 5.2-5.8

v. Temperature: keep it below 25 degrees centigrade for a luxurious growth. Where it exceeds this, provide a shade net cover

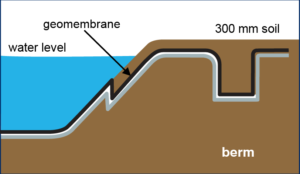

vi. Water: fresh water 10-15 cm in the multiplication pond, adequate water level in the pond is 4 inches

Steps on how to grow azolla

- select a pond site in a cool shaded location. Shade minimises evaporation, and encourages rapid growth. Ensure that that the pond site is close to a water source. To produce 1kg of azolla daily, the pond will be 2M (L) x 1.5M (W) x 0.15M (D) in dimension

- line the pond using a dam liner to prevent water loss through seepage into the soil

- add soil mixed with cow dung in the pond. Slurry can also be used. These are mixed with water and spread uniformly in the pond

- add 1kg of azolla culture

A simple azolla growing trough

How to grow azolla

Maintainance

- add 20g of super phosphate mixed with 1kg cow dung every 5 days to keep it’s growth vigorous

- replace the azolla crop after 6 months

- harvest the crop after 15 days by hand or a plastic scoop, then every 3 days afterwards to avoid overcrowding, and maintaining a large biomass. With good feeding, the yield is 1.5kgs – 1.6kgs every 3 days

- clean it thoroughly to remove the cow dung smell

- dry it or feed it fresh to livestock. It can also be mixed with other animal feeds

Azolla harvesting by hand

Harvested azolla in plastic containers

How to Grow Azolla

FAQs

1. How profitable is azolla farming in Kenya?

Azolla farming is profitable beacuse of its many uses. It can be grown commercially as;

- livstock feed

- a bio fertiliser

- as propagation material to sell to other farmers seeking to set up azolla growing units

2. What is azolla used for?

As a nitrogenous fertliser, and as an animal feed. It is easily digestible because of its high protein and low lignin content. It increases feed efficiency, daily anaimal weight gain, and milk production by 15% – 20%

3. Why is my azolla turning black?

It first turns brown due to too much exposure to sunlight, high temperatures, lack of nutrients in the pond or fungal / bacterial diseases. Eventually, the crop dies

4. Can azolla survive without sunlight?

No. This is important to note when fixing a shade net over it

5. What are the negative effects of azolla?

Azolla shades out other water plants, killing them together with fish and other aquatic animals. Its decay creates a strong odour which affects fish and other aquatic animals

6. What are the limitations of azolla?

It cannot grow in a waterless environment

7. Does azolla repel mosquitoes?

Yes it does by over 95%

8. Does azolla increase eggs production in chicken?

Yes it does because it provides protein, that adds weight to the bird

An azolla crop turning brown

Dam Liners Prices in Kenya

Dam liners prices in Kenya for irrigation by Grekkon Limited vary annually by raw material cost. These dam liners will be installed on reservoirs, or water tanks. Their purpose is to prevent water loss through absorption by the soil surface.

Our dam liner material is high density UV treated geomembrane. UV treatment is to slow down degradation by the sun during external use. Grekkon Limited’s dam liners for sale in Kenya are categorised according to thickness

A small water reservoir for vegetable irrigation with a 0.5mm dam liner installed by Grekkon Limited in Emabungo area, Vihiga county. Notice the fence around it fo safety reasons

Dam Liner Prices in Kenya

| Liner Thickness | Material Cost In Kes | Welding Cost In Kes | Installation Cost In Kes | AMOUNT In Kes |

| 0.5mm | 220 | 30 | 30 | 280 |

| 0.75mm | 300 | 30 | 30 | 360 |

| 1mm | 380 | 30 | 30 | 440 |

Introducing the 1.5mm dam liner for Kes 780/M square all inclusive

Notes

- Welding cost applies when the liner required is wider than 8M

- Installation cost is charged when a Grekkon Limited technician installs the liner

Dam Liners Material Thickness Application

- 0.5mm liners are for smooth surfaces without stones or rocks. It will work on a surface with murram. The life span is 8 to 12 years

- 0.75mm liners are for rough surfaces with some stones or rocks. The lifespan is 15 to 20 years

- 1mm liners are for stony or rocky surfaces. The lifespan is over 25 years

The choice of liner thickness is a factor of the liner size. A liner holding 10,000 cubic is thicker than one holding 500 cubic

Dam Liners Prices In Kenya

Processes Every Grower Should Know

I. How to calculate your dam liner size

- Measure your reservoir length (L), width (W) and depth (D) in meters

- Apply the formula; (L+2D+2) + (W+2D+2). This converts your 3D measurement to 2D

II. Steps to install your dam liner

- Clean up your reservoir floor to remove any debris that will perforate the liner

- Lay your liner at the center on the floor of the reservoir

- Spread it out to cover the entire floor, and the walls

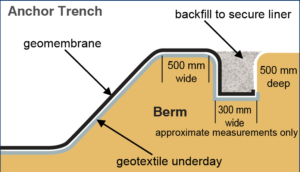

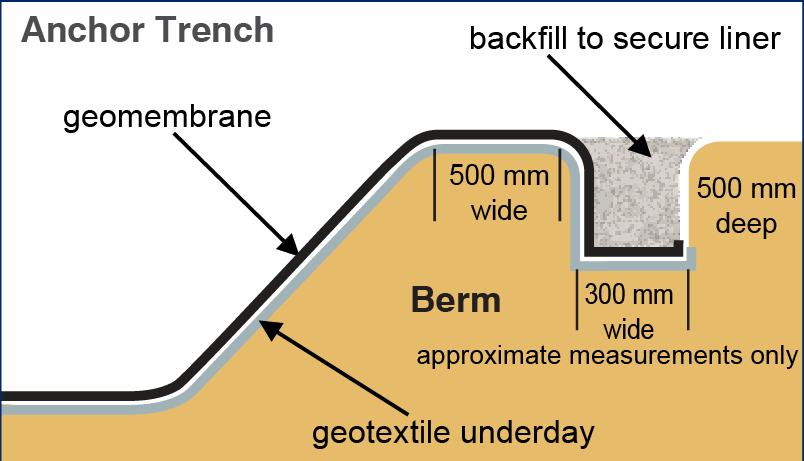

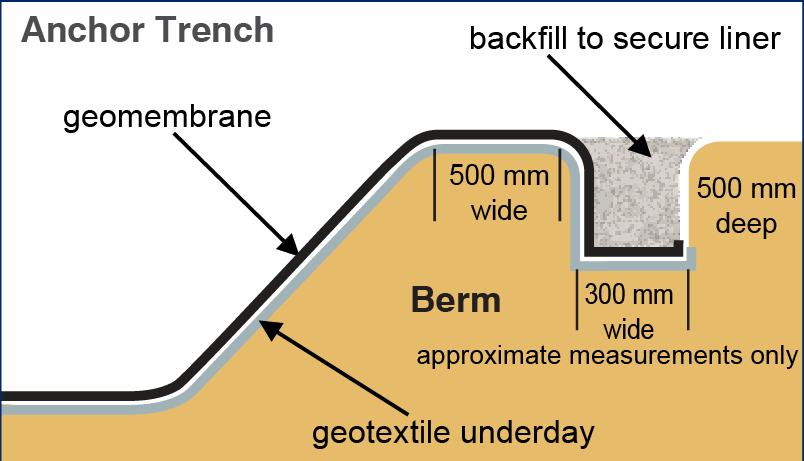

- Make a trench 1M away from the edge of the reservoir, all around it

- The trench measure 30cm/ 1ft deep by 30cm/ 1ft wide

- Tuck your liner in this trench, then cover it with lots of soil

III. How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

IV. How to Harvest Water Using Dam Liners

Factors to consider that will affect your dam liners prices in Kenya

a. Land size

The amount of water required for half an acre is less than that needed for 20 acres. The latter will harvest more water to irrigate the greater acreage, and the former will have less water harvested. The bigger the volume of water reserved, the larger the dam liner size

b. Location

The amount of rain fall is different in every climatic zone. Growers in the cool wet highlands have just a few dry months in the year, while farmers in the dry zones have more dry months than wet. In regions where the interval between rains is long, larger reservoirs are built for the same acreage as that in the cool wet location. Again, dry locations have very high water loss through evaporation. In this case, it is advised to set up a shade net over the water reservoir to manage this water loss

c. Ground Elevation

The farm gradient determines the location of the water pan. Some choose to have it at the lowest part so as to capture run-off water. If it is for crop irrigation, this water is either pumped uphill to a tank from where it flows back by gravity to the crop. Or it is pumped directly to the crop from the water reservoir. Others choose to locate the water pan on the highest point of the farm so that the water, through gravity flows out to the crop. In this case, the farmer does not retain run-off rain water from the farm. On a flat terrain, irrigation water is physically pumped out to either a high storage tank for onward gravity flow to the crop. Or directly to the crop

A low reservoir that collects run-off rain water

d. Farming System

The size of the water pan will differ for irrigation, compared with aquaculture or livestock production

e. Crop Type

Some crops are more water demanding such as leafy vegetables, than others such as herbs. Then some crops like onion are densely spaced while others are like avocado are sparsely populated in the farm. This will determine the water requirement

f. Irrigation System

Every irrigation system has it’s own unique water use. Drip irrigation conserves water while overhead irrigation through sprinklers or rain hose kits spends huge water volumes

g. Surface Texture

The surface texture of the water pan determines the dam liner thickness to install. For a smooth surface, a 0.5mm dam liner is ok. Where the surface is stony or rocky, then the 0.75mm or 1mm dam line is better

How To Install Dam Liners In Kenya

What is dam lining?

It is the lining of the floor and walls of a water pan with a geomembrane material. This material is impermeable and holds the water above it for agricultural use

To cover a reservoir with a dam liner is a simple yet complicated task. Proper dam liner installation in Kenya will guarantee good water collection for irrigation and domestic use. It requires proper coordination so as to achieve the intended objective. Before installation, one must learn how to measure a dam liner so as to determine the area of material needed for the water pan or tank. Grekkon Limited is your number one company in supply and installation of dam liners in Kenya

How do you measure a dam liner?

- Measure the length of the water reservoir

- Measure the width of the water reservoir

- Determine the depth from the center-most part of the water pan which is deemed as the deepest part

- Apply this formula (length+2 depth+2 meters) X (width+2 depth+2meters). The additional 2 meters in each set are for tucking the liner. The dam liner tucking distance from the edges is taken as 1M all around te water pan

Steps on How to Install Dam liners in Kenya

Water Pan Excavation

This is the first step and usually takes the longest time. Excavation is manual with handtools, or with a machine. Most common machines for dam excavation are backhoe loaders, bull-dozers and caterpillars. At excavation, the side walls are inclined at an angle to prevent collapse of the dam.

Read Also: How to join dam liners and Quality dam liners in Kenya by Grekkon Limited

Smoothening Of The Water Pan

This is to remove any sharp objects that damage the dam liner. Pour in water on the floor and sides to soften it.

Trench Making

Trenches are dug round the dam where the dam liner will be installed. The size of the trench will depend on the size of the dam and the dam liner thickness. The most popular trench sizes are 1ft deep by 1ft wide and 1.5ft deep by 1.5ft wide.

Observe the trench made around the water pan. it is 1M from the edges of the water pan, and this is where the dam liner will be tucked

How To Install Dam Liners In Kenya

- Place the dam liner in the reservoir. This way, it takes the shape of the reservoir

- The liner must have an allowance for overlap. Bury the overlap in the trench, then cover with soil for a smooth finish. The trench dimensions will be 0.45M to 0.6M deep, and 0.3M wide. Several casual labourers make the process as smooth as possible. Where no trench has been made, support the dam liner with sand/ soil bags to achieve the same result

- Install an inlet and an over flow. The inlet is a pipe from a river, borehole or from the roof gutter section. Dams that trap run off water have a silt trap with several chambers to trap stones, mud and other debris.

How To Weld Dam Liners

- This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit. The welded joints must be leak free for the dam liner to work effectively in the tank or water pan. Lined water pans are popular as water storage units for agricultural field crops irrigation in a country that has just one or two rainy seasons

Pond Liner Calculator

In this pond liner calculator article, we answer the following frequently asked questions

1. How is a dam liner calculated?

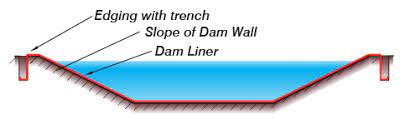

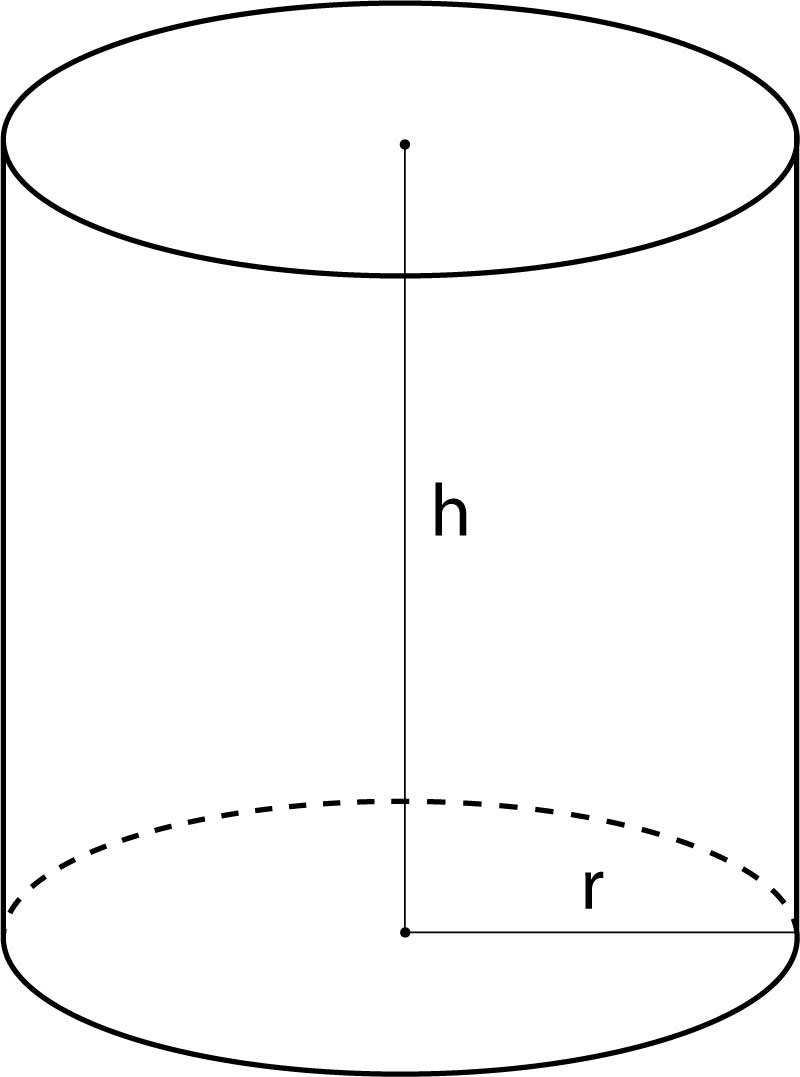

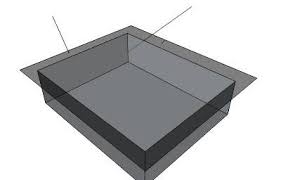

The formulae adopted depends the shape of the water pan. The water reservoir’s dam liner is calculated differently for a circular or oval water pan vis a vis that of a square/ rectangular one. Similarly, a square water tank has a different formulae from a circular one. A water pan with slanting edges has a different formulae from that with straight edges. Whether the water reservoir or tank is for irrigation, domestic or industrial application, the formulae is the same

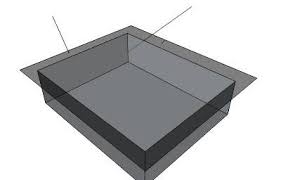

I. Square/ rectangular water reservoir or tank pond liner calculator

a. Square/ rectangular pond liner calculator for straight edges: Total length in meters: (length + 2depth + 2meters). Total width in meters: (width + 2depth +2meters). The additional 2meters on each side are for the overlap which is tucked in a trench for water reservoirs. For tanks, it’ll be 0.5M. Multiplying the total length with the total width gives the pond liner area in meters

Pond liner installation in a water reservoir with straight edges

Tucking is in a trench all around the water pan

How to trench and tuck your pond liner

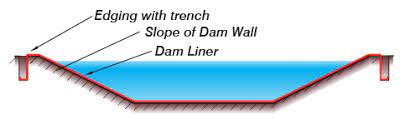

b. Square/ rectangular pond liner calculator for slanted edges: Total length in meters: (base length + 2slanting depth + 2meters). Total width in meters: (base width + 2slanting depth +2meters). Multiplying the total length with the total width gives the pond liner area in meters

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

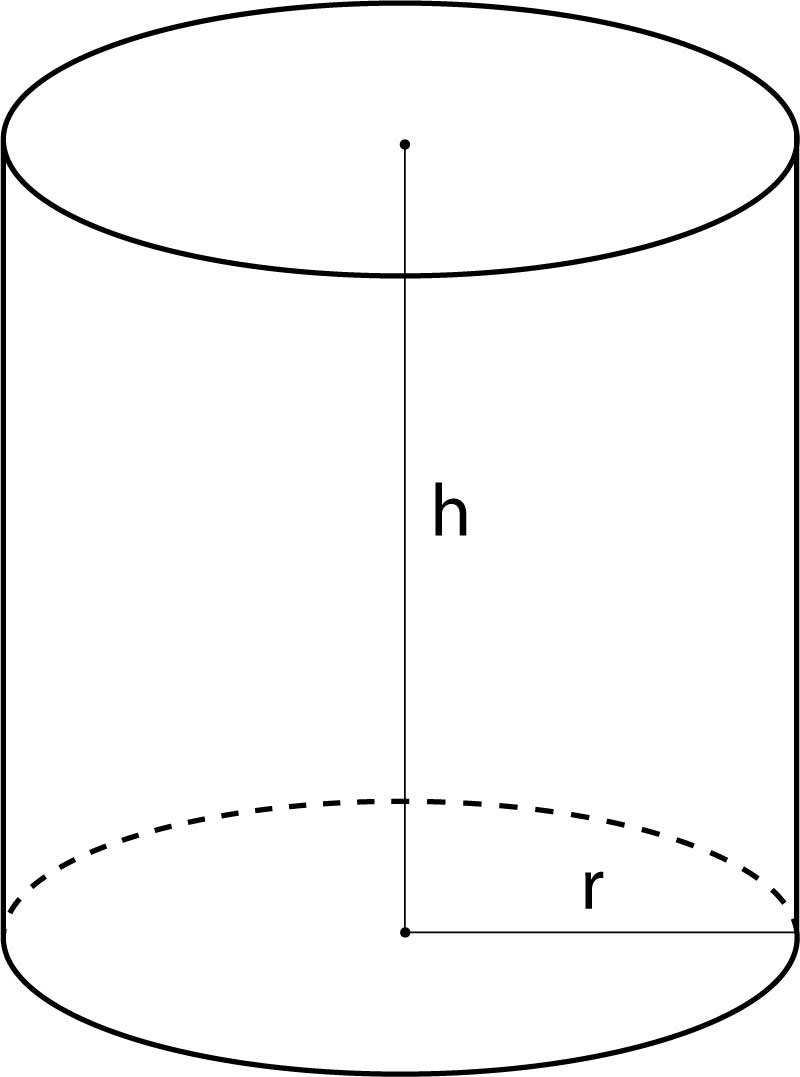

II. Circular pond liner calculator

Diameter + (2height/ depth) + (1meter). The 1meter is the external allowance that goes outside the tank as shown in the image below

A liner in a cylindrical tank

2. How do I calculate how much pond liner I need?

The size of the pond liner is according to the water pan or water tank area. The size of the water pan or tank is by volume, shown as; length by width by depth/ height. The liner size is by area, shown as; length by width. For this conversion, the formulas shown above work

The larger the water pan or tank, the larger the pond liner required

Dam Liner Company In Kenya

Grekkon Limited is the foremost dam liner company in Kenya. From material selection, to welding and installation, our professional teams train growers on all these aspects. It ensures that they make the right choice and why

This is according to the size and nature of their irrigation water reservoirs and tanks. These dam liners in Kenya are UV treated, HDPE geomembrane material in varying thicknesses and weights as tabulated below

| Liner Thickness | Liner Weight/ M SQ |

| 0.5mm | 460g |

| 0.75mm | 880g |

| 1mm | 910g |

The UV treatment reduces radiation damage which is high in tropical countries

A roll of 0.75mm dam liner

Dam Liner Prices In Kenya

Our dam liner cost in Kenya is broken down into; material, welding, and installation. Once a grower procures a dam liner, s/he will have it welded if the width exceeds 8M. If the farmer chooses for us to install, then the cost of installation applies.

| Liner Thickness | Material Cost (KES) | Welding Cost (KES) | Installation Cost (KES) | AMOUNT (KES) |

| 0.5mm | 220 | 25 | 25 | 270 |

| 0.75mm | 300 | 25 | 25 | 350 |

| 1mm | 380 | 25 | 25 | 430 |

How Are Dam Liners Calculated?

Before determining the dam liner size, one must understand the size of the reservoir or tank. This is by measuring the length, width, and depth/ height (for rectangular or square shaped reservoirs/ tanks). For circular or cylindrical tanks/ reservoirs, measure the diameter, and the depth/ height. The reason this is key is because our dam liner material comes in rolls. To make out the shape of the water pan or tank, the dam liner is cut in large bits from the roll and joined together. This is to create the 2 dimension size of the water reservoir or tank. For example; if the width of the dam liner on the roll is 8M, and the water pan requires a width of 15M. Then 2 pieces, one measuring 8M and another 7M in width from the roll are cut and joined to create the 15M width

How Do I Calculate How Much Dam Liner I Need?

The dam liner calculator is adapted to the shape of the irrigation water reservoir as illustated in the 3 different shapes below

- Sloped sides reservoir

The slope of the dam wall is shown as slanting length (SL) or slanting width (SW) in the dam liner calculator tabulation shown later in this page

2. Cylindrical circular tanks

3. Straight side reservoirs

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

Dam Liner Calculator

How much overhang should a pond liner have?

An overhang is the extra liner material that holds the main liner in the reservoir or tank. This excess material is held against the external wall of the tank, or tucked in a trench all around the reservoir to support the dam liner in place. It is covered with soil or stones in the trench. Another alternative to trenching is to lay sand bags on it. The weight of the sand bags holds the dam liner in place

After excavation, it is necessary to compress the mould of soil roundabout the water pan before making a trench

See below

Dam Liner Installation

Our dam liner rolls are 8M wide. So for any width beyond this, the additional size has to be welded on. Welding is carried out fully in the ware house for small liners, and partly in the field for large liners. This is to reduce bulkiness during transportation to site

When installing a dam liner in a reservoir, trench round about the reservoir. This anchor trench is where the liner will be tucked for support

The video below shows a farmer in Nandi county recounting the benefits he has received 2 years later after having his dam liner installed by Grekkon Limited

How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

Both equipment run on electric power. In off grid electricity locations, Grekkon Limited provides a generator to power the heat gun or wedge welding machine

Dam Liner Company In Kenya: Summary

Every dam liner size is available from our outlets countrywide. Besides supplying and installing liners, our technical team advises growers on;

- The right size of reservoir for a particular acreage

- How to properly excavate your reservoir

- How to select the right dam liner according to ; the reservoir size, surface texture, and one’s budget

Water Harvesting With Dam Liners

Water harvesting with dam liners in Kenya is a an important aspect of effective and consistent all year round irrigation. Grekkon Limited is the largest provider of the 3 main types of dam liners in Kenya. This is for water harvesting and aquaculture to smallholder and medium commercial farmers. We encourage every commercial crop farmer to excavate a water pan for off-season production. We then line this water pan with geomembrane material to hold water. Dam liners prevent water loss in the reservoir through seepage into the soil below. Produce cultivated during the off-season fetches better prices, and ensures a consistent farm income. Our dam liners have anti-UV treatment to protect them from long-term solar degradation, which extends their lifespan

A roll of 0.75mm dam liner

Water Harvesting With Dam Liners

Steps:

- Work out the area under irrigation, or to irrigate

- Determine the irrigation method. Each method consumes different amounts of water. We recommend drip irrigation as the most water efficient method

- Understand how long the dry off-season period is

- The 3 workings above will give an indication of the water quantity needed

- Work out the size of the water pan to excavate to hold this amount of water

- Calculate the dam liner size to install in this water pan

An illustration

An acre of strawberry measures 4,048 meters square. The method of irrigation is drip, and strawberry require 100 cubic litres weekly per acre (averagely). The dry period lasts for 32 weeks, so the amount of water needed is 3.2million litres or 3,200 cubic liters to last this long. This assumes zero rainfall in these 8 months, and that there is a shade net covering to prevent evaporation losses

The reservoir dimensions are 36M length x 36M width x 2.5M depth. The total liner needed for this is 1,849 meters square

A newly excavated reservoir with a dam liner covering

Dam Liner Types In Kenya

1. By material

1.1. High density polyethylene (HDPE) geomembrane. These are the most common types because they have additional use in making urban multi-storey gardens

1.2. PVC dam liners. The are soft but heavy. This makes them easier to weld and install

1.3. Low density polyethylene (LDPE). They are soft and light, hence the least popular because they have a short lifespan

HDPE geomembrane pond lining

2. By size

2.1. 0.5mm / 500 microns. For smooth surfaces or soil with light murram particles. It has a lifespan of 15 years

2.2. 0.75mm / microns. For lightly stony or rocky surfaces. It has a life span of 25 years

2.3. 1mm / 1,000 microns. Applied on moderately stony or rocky surfaces. Period of use is 35 years

2.4. 1.5mm /1,500 microns. For application in difficult terrain where the others will not hold

An irrigation water pan with dam liner material

Where to buy dam liners in Kenya

Where to buy dam liners in Kenya is from Grekkon Limited. The company offers the best UV-treated black high density polyethylene (HDPE) dam liners manufactured for tropical climates. Our pond liners for sale in Kenya line the walls and floors of water harvesting reservoirs. This is to prevent water loss through seepage into the soil. Changing rainfall patterns and unpredictable seasons are increasingly becoming a norm in Africa. This is why the need for agricultural water conservation is growing amongst farmers. Every farmer practicing irrigation has a water source

Where to buy dam liners in Kenya

| Thickness | Weight per meter square in Kgs | Price per meter square in KES |

| 0.5mm | 0.46kg | KES 220 |

| 0.75mm | 0.88kg | KES 320 |

| 1mm | 0.91kg | KES 420 |

Water pans lined with dam liners are a source of irrigation water storage. This water is from a larger source such as a lake, river, or borehole water, and also harvesting rain and run-off water. Besides irrigation of your crop, the pond liners on your water pan allows for commercial or subsistence fish rearing; the former to boost household income, the latter to supplement household protein

Where to buy dam liners in Kenya

Dam liners are available in the companies 6 branches located in; Athi river, Nairobi, Kisumu, Eldoret, Nyeri and Nyahururu. We supply pond liners either as rolls of 110M x 8M, 0r cut and welded into the client’s water pan’s specifications

Dam liner rolls by Grekkon Limited

HDPE pond liners cut from a roll and welded to tailor it to the water pan dimensions

Where to buy dam liners in Kenya

Positioning Your Water Reservoir For Irrigation

This depends on:

i. The source of water going into the water pan. If the source is from a lower altitude water source such as a river or lake, the water pan is at an elevated position so that with a water pump, the water is reticulated through irrigation water pipes to the water pan. If the water source is from rain water falling on the roofs or run-off, the water pun is positioned at a lower gradient

ii. Preferred irrigation method. If by sprinkler irrigation or rain hose kits which require high pressure from a water pump, the water pan will be situated at any point. If by low gravity pressure say for drip or button drip irrigation, then it will be at the highest point of the farm

Water harvesting using dam liners

Where to buy dam-liners in Kenya

How to Harvest Water Using Dam Liners

Factors to consider

1. Land size

The amount of water required for half an acre is less than that needed for 20 acres. The latter will harvest more water to irrigate the greater acreage, and the former will have less water harvested. The bigger the volume of water reserved, the larger the dam liner size

2. Location

The amount of rain fall is different in every climatic zone. Growers in the cool wet highlands have just a few dry months in the year, while farmers in the dry zones have more dry months than wet. In regions where the interval between rains is long, larger reservoirs are built for the same acreage as that in the cool wet location. Again, dry locations have very high water loss through evaporation. In this case, it is advised to set up a shade net over the water reservoir to manage this water loss

3. Ground Elevation

The farm gradient determines the location of the water pan. Some choose to have it at the lowest part so as to capture run-off water. If it is for crop irrigation, this water is either pumped uphill to a tank from where it flows back by gravity to the crop. Or it is pumped directly to the crop from the water reservoir. Others choose to locate the water pan on the highest point of the farm so that the water, through gravity flows out to the crop. In this case, the farmer does not retain run-off rain water from the farm. On a flat terrain, irrigation water is physically pumped out to either a high storage tank for onward gravity flow to the crop. Or directly to the crop

A low reservoir that collects run-off rain water

4. Farming System

The size of the water pan will differ for irrigation, compared with aquaculture or livestock production

5. Crop Type

Some crops are more water demanding such as leafy vegetables, than others such as herbs. Then some crops like onion are densely spaced while others are like avocado are sparsely populated in the farm. This will determine the water requirement

6. Irrigation System

Every irrigation system has it’s own unique water use. Drip irrigation conserves water while overhead irrigation through sprinklers or rain hose kits spends huge water volumes

7. Surface Texture

The surface texture of the water pan determines the dam liner thickness to install. For a smooth surface, a 0.5mm dam liner is ok. Where the surface is stony or rocky, then the 0.75mm or 1mm dam line is better

Before harvesting your water using dam liners, ensure that the water pan’s surface is free of debris as much as is possible. This will be stones, rocks, tree stomps, or sticks. This reduces the danger of your dam liner tearing as a result of perforation caused by the weight of the water squeezing the material against these particles

Trench 0.75M to 1M along the perimeter or circumference of the water pan. This trench is 1ft wide and 2 ft deep. Your dam liner edges will be tucked in here and covered with soil, gravel or stones to anchor it in place. Alternatively, use sand bags along the edges to hold your dam liner in place

Where to buy dam liners in Kenya

How Are Dam Liner Sizes Calculated?

Before determining the dam liner size, one must understand the size of the reservoir or tank. This is by measuring the length, width, and depth/ height (for rectangular or square shaped reservoirs/ tanks). For circular or cylindrical tanks/ reservoirs, measure the diameter, and the depth/ height. The reason this is key is because our dam liner material comes in rolls. To make out the shape of the water pan or tank, the dam liner is cut in large bits from the roll and joined together. This is to create the 2 dimension size of the water reservoir or tank. For example; if the width of the dam liner on the roll is 8M, and the water pan requires a width of 15M. Then 2 pieces, one measuring 8M and another 7M in width from the roll are cut and joined to create the 15M width

How Do I Calculate How Much Dam Liner I Need?

The dam liner calculator is adapted to the shape of the irrigation water reservoir as illustated in the 3 different shapes below

- Sloped sides reservoir

The slope of the dam wall is shown as slanting length (SL) or slanting width (SW) in the dam liner calculator tabulation shown later in this page

2. Cylindrical circular tanks

3. Straight side reservoirs

Where to buy dam liners in Kenya

Pond Liner Calculator Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

Where to buy dam liners in Kenya

How much overhang should a pond liner have?

An overhang is the extra liner material that holds the main liner in the reservoir or tank. This excess material is held against the external wall of the tank, or tucked in a trench all around the reservoir to support the dam liner in place. It is covered with soil or stones in the trench. Another alternative to trenching is to lay sand bags on it. The weight of the sand bags holds the dam liner in place

After excavation, it is necessary to compress the mould of soil roundabout the water pan before making a trench

See below

Where to buy dam liners in Kenya

How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

Both equipment run on electric power. In off grid electricity locations, Grekkon Limited provides a generator to power the heat gun or wedge welding machine

Where to buy dam liners in Kenya

A Step by step procedure on how to install dam liners

To learn how to install dam liners in your water pan or tank, consider the following factors

- Determine if;

1.1. It is a water reservoir

or

1.2 A water tank

Each storage unit has a different way of calculating the dam liner

2. Define the shape of the water pan or tank;

2.1. Is it circular/ oval or square/ rectangular?

2.2 Are the rectangular/ square sides steep or slanted?

The dam liner calculation formulae is different for each shape as illustrated later in this article

The second stage in how to install dam liners is to work out the dam liner size

A Grekkon Limited technician installing a dam liner in a water reservoir

Types Of Dam Liners

As a dam liner company, Grekkon Limited supplies and installs 3 types of dam liners in Kenya by thickness, and 2 types of dam liners by material. In this article, we answer many water harvesting using dam liners questions posed to us by growers

1. What type of dam liner is best?

1.1. Types of dam liners in Kenya – by material

High density polyethylene (HDPE) dam liners

This is what we supply and install most. This is because it is thin and lightweight which makes it easy to carry. They are tough with high tensile strength, hard to puncture, and stiff, which makes them less prone to sudden length tears. However, this stiffness makes welding more difficult. HDPE dam liners have the best UV resistance, and are safe for the environment because they do not emit chemicals. Their disadvantage is that they’re more difficult to repair when perforated. Our HDPE dam liners are in rolls from which we cut and tailor weld it to a water pan’s specifications

A HDPE dam liner installed by Grekkon Limited in Vihiga county, Kenya

Polyvinyl chloride (PVC) dam liners

We supply and install these but at a lessor scale. PVC dam liners are highly flexible, impermeable and tough. They are heavier than HDPE dam liners, but easier to weld as the material joins together more easily. They have the best resistance to chemicals and acids and so they are not easily corroded. This makes them the most suitable for land fills and chemical containment sites. Our PVC dam liners are factory fabricated panels that eases installation. The downside with PVC dam liners is environmental safety because they release chemicals as the PVC material degrades. This in the long-term is toxic to fish

A PVC dam liner installed by Grekkon Limited in a water pan in Kibwezi, Kenya

Low density polyethylene (LLDPE) dam liners

They are made from the same plastic as HDPE dam liners, and so share similarities. Being less dense than their HDPE cousins, they are softer, more flexible and more pliable. Being softer makes them less susceptible to stress cracking. High flexibility allows for easier under installation, and molding them around corners, nooks and crannies. Pliability means they conform best to rough terrain with little wrinkles

An LLDPE liner in a large water pan

1.2. Types of dam liners in Kenya – by thickness

- 0.5mm / 500 microns. This is for smooth surfaces and to hold low water volume (5,000 cubic liters and below)

- 0.75mm / 750 microns and 0.8mm / 800 microns. Works well in rough surfaces with few stones or murram. It will hold medium water capacity

- 1mm / 1,000 microns. Best for stony or rocky surfaces, and high capacity

- 1.5mm / 1,500 microns. Works on surfaces that the 1mm will not, and holds ultra high water volumes

2. Which is better: PVC or HDPE dam liner?

HDPE is better because it has greater tensile strength, and does not contaminate the environment

3. What is a good thickness for a dam liner?

The choice of thickness is determined by the surface and water volume. For instance, a 0.5mm dam liner is more appropriate for a concrete water tank holding 100 cubic litres than a 1mm dam liner

4. What are the 2 main types of dam liners?

HDPE and PVC dam liners are the most common dam liners in Kenya

5. How long does a dam liner last?

This depends on the thickness, material type and use. As a guideline though, 0.5mm thick dam liners last to 15 years, 0.75mm to 25 years, and 1mm to 36 years

6. Can I put a new dam liner over an old one?

The simple answer is yes, but remove any liquid, and solid debris on the old liner’s surface. Note that once the new one is placed, you cannot shift the old liner without affecting the new one. The new dam liner is not joined to the old dam liner in any way

7. How often do dam liners need to be replaced?

So long as the dam liner is functioning well, it is unnecessary to remove it. There is no replacement timeline

8. What is the best liner for a large water pan?

Large is relative. But for any water reservoir holding beyond 5,000 cubic litres, we recommend the 0.75mm or the 1mm thick dam liners

9. How do you hold a dam liner in a water pan?

There are 2 ways.

9.1. Trenching

This is where a 2 feet deep by 1 foot wide trench is excavated all round the circumference of the water reservoir. This trench is 0.75M to 1M from the edge of the water pan. The dam liner is tucked in here then covered with soil, gravel or rocks/ stones

The edges of a newly installed HDPE dam liner in a water pan tucked in a trench and covered with soil

9.2. Sand bags

Bags filled with soil, sand or gravel are laid on top of the dam liner edges to anchor it in place

The different types of dam liners does not affect the holding method

10. Can you join 2 dam liners together?

Yes. Pieces of dam liner welded together make a continuous sheet

11. Can you glue 2 dam liners together?

The best way to join dam liners is by welding because it is permanent

12. Can you cut a dam liner?

Yes. We cut and weld together dam liner sheets from large rolls to tailor it to the water pan’s dimensions

13. Can you put gravel on top of a dam liner?

Yes you can especially if it is for support on the edges

What to consider when choosing a dam liner

- The surface texture. Install a thicker liner for rougher surfaces

- Water volume. The larger it is, the thicker the dam liner

- Purpose. If it will hold chemicals or acids, then the PVC dam liner is best because it is the most resistant