Dam Liner Company In Kenya

Grekkon Limited is the foremost dam liner company in Kenya. From material selection, to welding and installation, our professional teams train growers on all these aspects. It ensures that they make the right choice and why

This is according to the size and nature of their irrigation water reservoirs and tanks. These dam liners in Kenya are UV treated, HDPE geomembrane material in varying thicknesses and weights as tabulated below

| Liner Thickness | Liner Weight/ M SQ |

| 0.5mm | 460g |

| 0.75mm | 880g |

| 1mm | 910g |

The UV treatment reduces radiation damage which is high in tropical countries

A roll of 0.75mm dam liner

Dam Liner Prices In Kenya

Our dam liner cost in Kenya is broken down into; material, welding, and installation. Once a grower procures a dam liner, s/he will have it welded if the width exceeds 8M. If the farmer chooses for us to install, then the cost of installation applies.

| Liner Thickness | Material Cost (KES) | Welding Cost (KES) | Installation Cost (KES) | AMOUNT (KES) |

| 0.5mm | 220 | 25 | 25 | 270 |

| 0.75mm | 300 | 25 | 25 | 350 |

| 1mm | 380 | 25 | 25 | 430 |

How Are Dam Liners Calculated?

Before determining the dam liner size, one must understand the size of the reservoir or tank. This is by measuring the length, width, and depth/ height (for rectangular or square shaped reservoirs/ tanks). For circular or cylindrical tanks/ reservoirs, measure the diameter, and the depth/ height. The reason this is key is because our dam liner material comes in rolls. To make out the shape of the water pan or tank, the dam liner is cut in large bits from the roll and joined together. This is to create the 2 dimension size of the water reservoir or tank. For example; if the width of the dam liner on the roll is 8M, and the water pan requires a width of 15M. Then 2 pieces, one measuring 8M and another 7M in width from the roll are cut and joined to create the 15M width

How Do I Calculate How Much Dam Liner I Need?

The dam liner calculator is adapted to the shape of the irrigation water reservoir as illustated in the 3 different shapes below

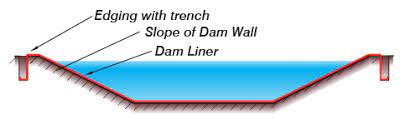

- Sloped sides reservoir

The slope of the dam wall is shown as slanting length (SL) or slanting width (SW) in the dam liner calculator tabulation shown later in this page

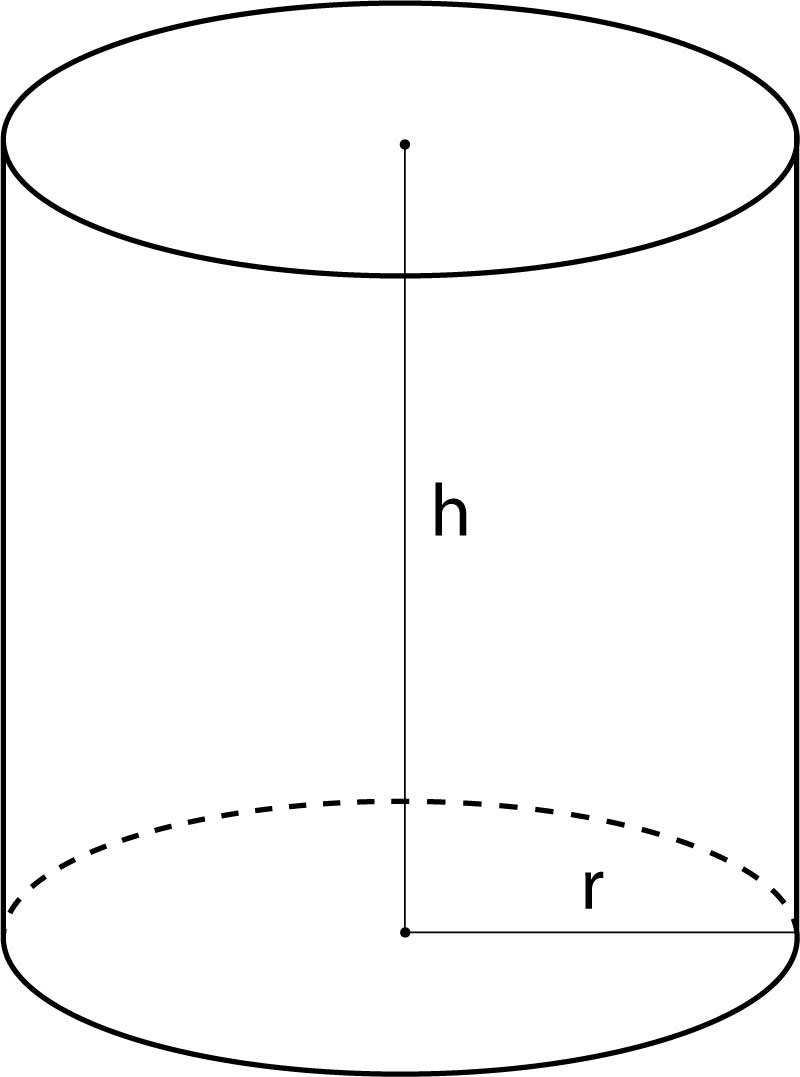

2. Cylindrical circular tanks

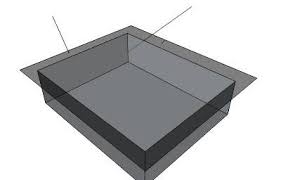

3. Straight side reservoirs

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

Dam Liner Calculator

How much overhang should a pond liner have?

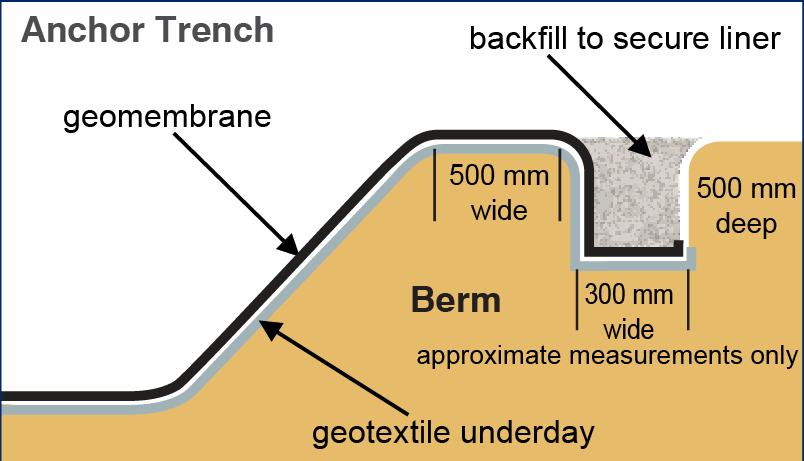

An overhang is the extra liner material that holds the main liner in the reservoir or tank. This excess material is held against the external wall of the tank, or tucked in a trench all around the reservoir to support the dam liner in place. It is covered with soil or stones in the trench. Another alternative to trenching is to lay sand bags on it. The weight of the sand bags holds the dam liner in place

After excavation, it is necessary to compress the mould of soil roundabout the water pan before making a trench

See below

Dam Liner Installation

Our dam liner rolls are 8M wide. So for any width beyond this, the additional size has to be welded on. Welding is carried out fully in the ware house for small liners, and partly in the field for large liners. This is to reduce bulkiness during transportation to site

When installing a dam liner in a reservoir, trench round about the reservoir. This anchor trench is where the liner will be tucked for support

The video below shows a farmer in Nandi county recounting the benefits he has received 2 years later after having his dam liner installed by Grekkon Limited

How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

Both equipment run on electric power. In off grid electricity locations, Grekkon Limited provides a generator to power the heat gun or wedge welding machine

Dam Liner Company In Kenya: Summary

Every dam liner size is available from our outlets countrywide. Besides supplying and installing liners, our technical team advises growers on;

- The right size of reservoir for a particular acreage

- How to properly excavate your reservoir

- How to select the right dam liner according to ; the reservoir size, surface texture, and one’s budget