Suction Hose Pipes

Grekkon limited’s suction hose pipes for water pumps in irrigation are available as 2″, 3″ and 4″ diameter hoses. Our green Polyvinyl Chloride (PVC) suction hose pipes are designed to withstand high vacuum pressure without collapsing. This is why they are ringed internally to hold the tubing in place during water pumping. This unique feature distinguishes them from other irrigation pipes

Our suction hoses for irrigation work with diesel and petrol generator water pumps, and electric centrifugal water pumps

A 2″ diameter suction hose pipe. Notice the dark green rings that allow it to withstand high pressure pumping without the walls collapsing

Suction Hose Pipes Prices In Kenya

| Pipe Diameter | Price per M |

| 2″ | KES 460 |

| 3″ | KES 810 |

| 4″ | KES 1,430 |

Suction Hose Pipes

FAQs

1. What is a suction pipe?

It is a pipe that draws water from source to the water pump for onward evacuation. It is a crucial component of every water pumping system

2. How does a suction system work?

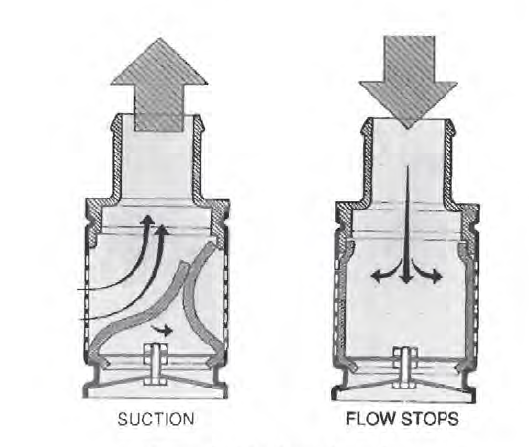

By creating a partial vacuum that draws water into it’s hollow space. This water is conveyed to the pump through the suction pipe

3. What is the function of a suction pipe?

- To draw water from the source and deliver it to the water pump

- It plays a role in the overall friction loss of the system. The larger the diameter, the lesser the frictional losses

4. What is the maximum length of a suction pipe?

8M or 26.4 feet. The suction distance is determined by the altitude. At sea level, the distance is longer than in high altitudes

5. Where is the suction connected to a water pump?

It is connected to the inlet portal of a water pump. The diameter size of the inlet determines the size of the suction pipe; they must be equal

This video illustrates a 3″ suction pipe feeding water a high diesel water pump during irrigation

6. How long can a suction pipe be on a water pump?

Not more than 8M. The higher the vertical pumping head of the water pump, the shorter the suction pipe is

7. What are the components of a suction system?

- the water source. This will be a stagnant reservoir, a flowing river or a storage unit such as a tank

- a foot valve. is an accessory attached at the base of the suction pipe. It prevents the water from flowing backwards when the water pump ceases. This way, the water is maintained in the suction pipe when the water pump isn’t working, thus sustaining a suitable prime for the water pump, and preventing pump burnout

A 3″ and 2″ plastic foot valve

How a foot valve works

- the suction pipes for water pumps which evacuate the water from the source to the water pumps

- a water pump to receive for onward pumping of the water from the reservoir

8. How long can a suction pipe be on a water pump?

For as long as it is pumping

9. What is the minimum suction pressure?

0.6M. The best is 1.5M above the net positive suction head required (NPSHR). NPSHR is a fuction of the pump design

Borehole Drilling Cost In Kenya

Grekkon Limited’s borehole drilling cost in Kenya through a mechanical drilling rig is dependent on 2 factors:

- The borehole drilling method; air v mud drilling

- Casings type to install; PVC v steel casings

- The geographical drilling location; determines the mobilisation cost

A Grekkon Limited borehole drilling rig on site at Matuu area, Machakos county

The borehole drilling method

There are 2 borehole drilling methods;

I. Air drilling / pneumatic percussion drilling is an under-balanced drilling technique (UBD). Here, compressed air or nitrogen is used to cool the drilling bit and extract the cuttings of a well-bore instead of fluids. this is carried on stable ground with a proper rock formation

II. Mud rotary drilling. The fluid is pumped down the hollow drill pipe (kelly) and forced out of jets in the drill bits. It is an open hole reciculatory drilling method. Chemicals used here are; Bentonite clay (Gel), Barium sulphate (Barite), Calcium carbonate (chalk), and Hematite

The location. The further it is from our branches, the higher the mobilisation cost

Our borehole drilling price in Kenya varies with the the drilling method, which is determined by the rock structure

Borehole Drilling Price In Kenya

By Drilling Method

| Drilling Method | What it entails | Price in KES Per Meter |

| 1. Air drilling | Drilling on stable ground that has a proper rock formation beneath | KES 6,500 |

| 2. Mud drilling | Drilling on loose ground that has no or minimal rock beneath | KES 14,050 |

Borehole Drilling Cost in Kenya

Details

| Process | Cost Per Meter- Air drilling method | Cost Per Meter- Mud drilling method | |

| 1 | Mobilisation | KES 420 | KES 420 |

| 2 | Drilling | KES 3,220 | KES 11,270 |

| 3 | Casing | KES 2,269 | KES 2,569 |

| 4 | Graveling | KES 280 | KES 280 |

| 5 | Well development | KES 70 | KES 70 |

| 6 | Test pumping | KES 420 | KES 420 |

| 7 | Water chemical analysis | KES 21 | KES 21 |

| Total | KES 6,700 | KES 15,050 |

- Mobilisation is the movement of human resource and equipment to the borehole drilling site

- Drilling is the actual sinking of the 8″ diameter well in the ground

- Casing is the installation of PVC or metallic 6″ diameter tubes to support the well, keeping it from collapse. Those along the water aquifer are slotted to allow in water into the well. The slots are 1mm to 2mm in size

- Graveling is the application of gravel in the 2″ gap between the well and the casings. Graveling holds the casings in place and also sieves the water

- Well development is the cleaning of the well to remove debris

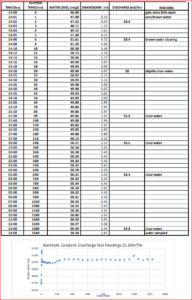

- Test pumping is the process of pumping out water for 24 hours from the borehole with a large submersible water pump, powered an equally powerful generator. This establishes the water recharge rate (yield of the borehole) given in cubic litres per hour, and the static water level. The test pumping results determine the type of electric or solar submersible water pump install in the well

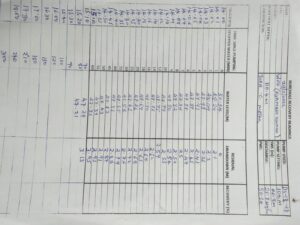

- Water chemical analysis is the last stage. A sample of water is analysed in the laboratory to determine it’s chemical composition. With these results, a grower assesses the suitability of the water for irrigation for specific crops according to their salt/ salinity tolerance

A test pumping report from a borehole drilling service by Grekkon Limited

A water analysis report from a newly drilled well

Cost of Drilling A Borehole in Kenya

By Geographical Location

| County | Cost (Min) | Cost (Max) |

| Nairobi | KES 6,500 | KES 9,500 |

| Kajiado | KES 6,500 | KES 9,500 |

| Machakos | KES 6,600 | KES 9,500 |

| Kitui | KES 6,800 | KES 9,500 |

| Makueni | KES 6,700 | KES 9,500 |

| Kiambu | KES 6,500 | KES 9,500 |

| Nakuru | KES 6,800 | KES 9,500 |

| Kisumu | KES 7,500 | KES 9,500 |

| Turkana | KES 8,000 | KES 9,500 |

| Bungoma | KES 6,900 | KES 9,500 |

| Busia | KES 7,700 | KES 9,500 |

| Narok | KES 6,800 | KES 9,500 |

| Mombasa | KES 7,500 | KES 9,500 |

| Kilifi | KES 7,500 | KES 9,500 |

| Kwale | KES 7,600 | KES 9,500 |

| Baringo | KES 6,900 | KES 9,500 |

| Siaya | KES 7,600 | KES 9,500 |

| Homabay | KES 7,600 | KES 9,500 |

| Uasin Gishu | KES 6,900 | KES 9,500 |

JD Diesel Water Pumps

JD (Jiang dong) diesel water pumps in Kenya by Grekkon Limited are of varying specifications for agricultural use in irrigation. This specifications are in regards to; the engine power, the head, and the flow rate

Our JD diesel water pumps consist of a diesel engine, and a horizontal single-suction, single-stage, centrifugal water pump. The water pump is made from cast iron

The water pump. It is rated by inlet/ outlet pipe size, head, and flow rate

The engine. It is rated in horsepower (Hp). The higher the HP, the more powerful it is

JD Diesel Water Pumps Characteristics

- high efficiency

- wide performance range

- safe and stable operation

- long service life because the cast iron impeller and volute reduce vibration and wear on the mechanical seal and engine

- convenient installation and maintenance

- can channel hot water, abrasive or corrosive liquids by changing the material of the water pump’s flow-through components, the form of the seal and adding a cooling system

Working Principal

After the start, the impeller rotates rapidly so that the water in the impeller channel flows towards the volute. During this time, a vacuum is formed in the inlet, and water flows from the suction pipe to the pump through the impeller channel

The right most critical terms when identifying the right pump performance is water volume and the lift/ head. Generally, a trade -off occurs between head and flow with an increase in one causing a decrease in the other and vice versa. Head refers to the gains or losses in pressure caused by gravity and friction as flows through the system. The lift is the vertical distance from the water line to the center line of the impeller

The greater the lift and the water volume required, the larger the engine power. For instance, to achieve a flow rate of 80 cubic litres per hour, at a head of 100M, then the engine power must be from 22Hp and above

JD Diesel Water Pumps Prices

| Model | Specs; head, flow rate, outlet size, and horsepower | Price in KES |

| JD | 65M, 38cubic per hour, 2″ and 14Hp | KES 113,000 |

| JD | 65M, 38cubic per hour, 2″ and 16Hp | KES 116,000 |

| JD | 65M, 38cubic per hour, 2″ and 18Hp | KES 129,000 |

| JD | 65M, 38cubic per hour, 2″ and 22Hp | KES 141,000 |

| JD | 100M, 80 cubic per hour, 3″ and 22Hp | KES 148,000 |

| JD | 65M, 38cubic per hour, 2″ and 24Hp | KES 158,000 |

| JD | 100M, 80 cubic per hour, 3″ and 24Hp | KES 165,000 |

| JD | 65M, 38cubic per hour, 2″ and 30Hp | KES 172,000 |

| JD | 100M, 80 cubic per hour, 3″ and 30Hp | KES 180,000 |

Complete units of JD diesel water pumps by Grekkon Limited

When assembling a JD diesel water pump, use the right steel frame gauge to hold the unit. Ensure that the rubber pulleys joining the engine to the water pump have the right tension

Greenhouse Paper In Kenya

Grekkon Limited’s greenhouse paper in Kenya is of various rent characteristics. These characteristics determine it’s overall performance on the crop. The paper choice is the same irrespective of the greenhouse type by shape, or by structural material. Our greenhouse paper price in Kenya is Kes 96/M sq irrespective of the polythene properties

Greenhouse Paper In Kenya; Properties

- Thickness. 200 microns/ 0.2mm

- Colour . Clear or yellow

– clear paper allows more light. This is good for fruiting crops such as tomato, strawberry, capsicums, and peppers. This is because more light has higher photosynthesis, which equates to more food for the plant. It is necessary for bi-color or multi -color flowers to enhance the different colors

– yellow paper will be for leafy vegetables, herbs, spices, and mono color flowers. These require less food as they are not fruiting

3. Width 5.5M, 8M, 16M. This not split but supplied as such to the grower

4. Roll length of 100M. The roll is cut as per client’s ordered length

5. UV treated. UV treatment blocks off excess UV light which in turn enhances the greenhouse paper lifespan. Our UV treatment is for 3 years/ 36 months. This warranty is on the paper

6. Anti-drip properties. Anti drip treatment prevents dew drop lets from forming on the greenhouse paper. Dew formation is as a result or crop respiration which releases moisture from the plant. Dew droplets falling or crops in the greenhouse pr-dispose the crop to fungal infections. The droplets also refract light, limiting the amount of light falling on the crop

How to choose your greenhouse polythene

- By crop. Is it a leafy or fruiting vegetable? Is is s mono or bi/ multi-coloured flower? This determines the paper color

- By width. There are different widths to choose from based on your greenhouse structure size

When the greenhouse paper tears, we provide a greenhouse repair tape that has the same characteristics as the greenhouse paper

FAQs

I. How much is greenhouse polythene in Kenya?

Greenhouse polythene price in Kenya

| Price | Treatment |

| Kes 95/M sq | With anti -UV only |

| Kes 120/M sq | With additional anti-drip treatment |

II. What plastic can be used for greenhouse?

Yellow or clear plastic are the choices for a greenhouse cover

III. What is the best poly for a greenhouse?

As explained above, the right greenhouse plastic depends on the crop type

IV. How do you attach polythene to a greenhouse?

For a metallic greenhouse, steel profiles and wiggle wires secure the paper against the steel frame

V. How long does polythene last on a greenhouse?

Our anti-UV block treatment is guaranteed for 36 months use. However, the paper itself will last for 5 years

VI. How thick should greenhouse poly be?

200 to 220 micron

VII. How often do you replace greenhouse plastic?

We recommend every 3 years so which is when the anti-UV block ceases

How to Keep Your Greenhouse Polythene Tight

- Spread out the paper on the greenhouse structure early in the morning or late in the evening when he temperature is below 20 degrees celcius. If it’s too hot, the paper will tear on contraction when it gets cold. If it’s too cold, the paper will sag when the temperature rises

- Roll it or pull it from one end to the next frame or runner and secure it with a profile and wiggle wire. Then stretch it again for this point to the next and so on

- Avoid covering in the afternoon when it is very windy as this will cause the paper to tear

How To Maintain Your Greenhouse Sheet

Observing these habits will keep your greenhouse polythene price in Kenya at the barest minimum

- Have a greenhouse tape for minor repairs when the paper is torn. Grekkon Limited’s greenhouse tape is UV resistant, trans-parent and is designed for outdoor use

- Clean your greenhouse cover monthly to prevent algae, moss, and dust which inhibit light from shining through

- Change it at the right time, which is when the anti-UV treatment expires

Caution: Do not use your greenhouse polythene in awater pan or tank to store or harvest irrigation water

Greenhouse repair tape. It has the same qualities as the greenhouse paper

Greenhouse polyethylene price in Nairobi

This is Kes 96/ M sq in Nairobi and all our up country branches

Overhead Sprinklers For Irrigation

Grekkon Limited is an irrigation equipment supplier in Kenya. We design, supply, and install all types of overhead sprinklers for irrigation systems, for every acreage and crop. Our overhead sprinklers for irrigation in Kenya are of different types, for different crops, acreage and locations. This is why our technical or agronomy team will visit a grower who needs to install one

It is to assess the land layout and size, topography, water location, water volume, existing water pump if any, and the crop. Through this survey, we recommend the most appropriate sprinkler irrigation kit for the grower based on their budget. For instance, a grower with 100 acres of orchard will have a different sprinkler from a 100 acres of a park covered with grass. Similarly, a farmer on an 1/8 acres of cabbage will have a different sprinkler irrigation kit than the one with 30 acres of cabbage

Overhead Sprinklers For Irrigation

Types

We have these 5 overhead sprinklers for sale types shown below available. For most, there are both metallic and plastic versions. Metallic sprinklers have a longer lifespan, but are costlier and heavier. Plastic sprinklers are lighter, cheaper, but have a shorter period of operation. The body material does not affect the pressure rating, inlet and outlet sizes or the water discharged. For technical details on each type, click on the title links given for every sprinkler

- Rain gun sprinklers for medium-sized to large acreage. Available sprinkler sizes are; 1″, 1-1/4″, 1-1/2″, 2″, and 2.5″. We supply and install the double nozzle PY, Atom, and flange type rain guns. The latter are for broad acreage and require very high water volume, and high operating pressure

An ordinary size rain gun sprinkler at work after installation by Grekkon Limited

2.5″ giant flange type rain

A flange type rain gun video at work

2. Plastic or brass impact sprinklers for small to medium sized acreage. Our sizes are; 1/2″, 3/4″ and 1″ which have either 2-way, 3-way or 4-way nozzles

Plastic impact sprinklers

3. Mega-net sprinklers for small to medium-sized areas. We have the 1/2″, 3/4″ and 1″ which have a spray angle of 180 degrees

A mega net sprinkler

4. Micro sprinklers for orchards and small areas with a spray angle of 360 degrees

Micro sprinklers in an orchard

5. Pop up sprinklers for lawn irrigation. Our sizes are1/2″ and 3/4″ which spray up to 360 degrees

A lawn pop up sprinkler

6. Butterfly mini sprinklers for small gardens or and lawns available as 1/2″

How to choose your overhead sprinklers in Kenya

- Land size. Rain guns for large acreage, and micro-sprinklers for small plots of land

- Crop type. Pop-ups for lawn irrigation, all other sprinklers for field crops

- Ground elevation. Gravity power from high elevations will swing micro and impact sprinklers. Rain guns, Meganets, and pop-ups work with water pumps

- Grower’s budget. It determines the sprinkler type and number of units to install

Our sprinkler irrigation system design considers the above 4 factors during our site visits conducted before a sprinkler irrigation system is installed

Components of an overhead sprinkler irrigation system

- Mainline. This is PVC, HDPE, or GI to supply water from the source. It will be connected directly to the sprinkler riser pipe, or to the sub-main line

- Sub mainline. This one is connected directly to the sprinkler rise pipe, or to the sprinkler itself from the mainline. It is also PVC, HDPE, GI or a delivery/ layflat pipe

- Riser pipe. This receives water from the main line or sub-main line to the sprinkler It is also PVC, HDPE, or a GI

- Tripod or pipe stand. It is the sprinkler’s support structure

- Gate valves. They allow or block water flow to the sub mainline

Overhead sprinkler prices in Kenya per acre

- Rain gun sprinkler system from Kes 65,000

- Impact and Mega-net sprinklers from Kes 50,000

- Butterfly and Micro jet sprinklers from Kes 85,000

- Pop-up sprinklers from Kes 120,000

FAQs

A. What are the pros and cons of an overhead sprinkler irrigation?

I. Overhead sprinkler irrigation advantages

- There is a wide choice to select from

- It is easy to install

- It is cheaper than drip irrigation

- Easy to move from one point of the farm to another

II. Disadvantages

- It is water wasteful

- During strong winds, water distribution is uneven

- High running cost because a water pump is needed

- It requires labour to move it from one location to another if it’s a portable system

B. How does an overhead sprinkler irrigation system work?

- Water is pumped under high pressure from the source; tank, reservoir, lake, river to the mainline

- From the mainline, it is distributed to the sub-main lines

- From the sub-mainlines, it enters the sprinklers under pressure. This pressure swings the sprinkler in a circular motion

- The sprinkler breaks the water into fine droplets, which fall on the crop

C. How do I choose a water pump for my sprinkler system?

Consider the following when selecting a sprinkler water pump

i. Pressure rating of the sprinkler. The water pump’s pressure rating must exceed that of the sprinkler to compensate for pressure losses in the piping system. Grekkon Limited’s technical team advises growers on the best match. The larger the pipe diameter, the lower the pressure loss along the horizontal pumping distance. The longer the horizontal and vertical pumping distance, the greater the pressure loos. Pressure loss during irrigation water reticulation is also as a result of leakages along the piping system

ii. Discharge rate of the sprinkler. Like the pressure rating above, this will be higher for the water pump to cater for any fluid losses

iii. Inlet diameter of the sprinkler. That of the pump has to match this

D. Which sprinkler head is best?

Rotor sprinklers are the most efficient sprinklers in the market. They have the least run-off, and irrigate slowly, hence less wastage

Tomato Drip Kit Price

Tomato drip kit price in Kenya by Grekkon Limited is by acreage. Our drip irrigation prices range as; kitchen gardens, 1/8th acre, 1/4 acre, 1/2 acre, 3/4acre and 1 acre. The components of these tomato drip are; HDPE pipe. The diameter ranges from 1″ to 1-1/2″ according to the size of the area HDPE fittings. […]

Cabbage Farming in Kenya

Cabbage farming in Kenya through irrigation requires even moisture to produce good heads. Our cabbage farming irrigation systems are; drip irrigation, sprinkler systems irrigation, and rain hose kits irrigation. Farmers’ cabbage water requirements are independent of the varieties grown. The best cabbage varieties to grow in Kenya are hybrids, which require consistent irrigation during growth. Successful cabbage farmers who supply the cabbage market in Kenya water 25 to 37 litres weekly. Good cabbage head sizes weighing 5kgs make it easy for a grower to choose where to sell cabbages in Kenya. Below is a review of cabbage irrigation farming requirements by systems

Drip irrigation in cabbage

1. Cabbage farming in Kenya; how to install a drip irrigation system on cabbage

- Bed making

Your beds will be 1M wide to allow for 3 rows of drip lines, and 30cm high for good drainage. Drainage is key to prevent root rot for cabbage as a result of too much stagnant water.

- Drip irrigation tapes laying

2 rows of drip lines per bed. Each drip line row is 20cm apart and the line is 20cm from the edge of the bed. Without beds, each row is 30cm apart

Rain hose irrigation in a cabbage farm

2. How to install a sprinkler irrigation system or rain hose irrigation kit

If you will not make beds, as shown above, then your cabbage spacing is 60 cm apart for rows. The inter-crop spacing is 30 cm to 45 cm. Place your sprinklers or rain hose pipes according to the radius of spray for each to cover the entire area.

Overhead or sprinkler irrigation on cabbage

Cabbage Farming in Kenya FAQs

- 1-acre drip irrigation kit; Kes 145,000

- 1/2 acre drip irrigation kit; Kes 75,000

- 1/4 acre drip irrigation kit; Kes 40,000

- 1/8 acre drip irrigation; Kes 25,000

Use sparsely spaced drip emitters 30cm apart. This cabbage drip irrigation system will water every plant and they will be no irrigation dry shadows. Irrigate in the morning hours and avoid late evening irrigation

Yes. A cabbage plant will require up to 1inch or 25 litres per meter square weekly during the early stage. At maturity, this will be 2 inches/ 50 litres per meter square under dry conditions. Too much water causes root rot, so monitor that the soil is not overwatered

Stop watering onions 7 days before harvest. This improves the shelf life

Grekkon Limited’s drip irrigation systems operate at 10 to 35 PSI

Yes. 10 to 12 hours of sunlight for head formation in the tropics

Yes. Half an inch/ 12.5 litres per meter square of water 4 times a week is enough.

Yes

Irrigation company in Nyahururu

The story of an irrigation company in Nyahururu goes like this….In 2017, two Kenyan agri-prenuers came together to establish an irrigation systems firm to serve small to medium scale commercial farmers in Kenya. This was by providing tailored professional irrigation systems set up solutions that were within these farmers’ budgets. At the same time, improving the clients’ overall yield, and income from farming. The motivation to focus on this niche was because of the presence of large international irrigation service providers. Their clientele were the large ornamental, cereal and vegetable growers. Smaller growers had to fend for themselves because they were never a priority for these large corporates.

The other objective was to do further by offering expert irrigation, greenhouse, water pumps, and dam lining expertise to these small scale to medium scale commercial farmers, who had no professional entity to consult for such. This was through physical site visits to carry out assessments, provide advice, and carry out irrigation project reviews afterwards. And so, Grekkon Limited – Irrigation Hub was born. It was headquartered in Nairobi, Kenya’s capital, and in August 2020, Grekkon Limited opened Nyahururu irrigation hub in Nyahururu town.

The irrigation company in Nyahururu serves farmers in; Nyandarua, Nakuru, Laikipia, and Samburu counties. It is located along the Olkalau- Nyahururu road.

Innovation

Grekkon Limited is the first irrigation systems company in eastern Africa to introduce the rain hose irrigation system. This new product solved many irrigation challenges for commercial vegetable and corn farmers. The company is the market leader in research and commercialization of natural solar dryers. Each unit designed to meet the product or market drying requirements. Today, Grekkon Limited is the largest supplier of natural solar dryers in Northern Kenya, Nakuru, Laikipia and Samburu regions.

Team

Grekkon Limited’s resounding success is largely due to its team of field professionals in Nyahururu. They provide engineering, commercial, and technical services. In a first in the market, the company organizes ‘training days’ in various regions of the counties. Here, where growers come to learn of new and existing technologies. This knowledge sharing module has proved effective in addressing basic irrigation challenges that farmers go through. It has created trust in the company’s expertise.

Irrigation Company in Nyahururu

The Future

There is a growing number of medium scale farmers living in the cities, but farming in the upcountry. The need to create a web-based irrigation monitoring system is more pronounced than ever. Grekkon Limited’s IT team is developing a gadget responsive tool. It will enable farmers to irrigate and fertilise (through fertigation) their farms remotely. It also woks s a moisture monitoring tool to alert growers when crop moisture levels fall below normal levels.

Wooden Greenhouse Prices in Kenya

Wooden greenhouse prices in Kenya by Grekkon Limited are by size and choice of timber. This low cost greenhouse construction in Kenya takes the same amount of time to build as metallic greenhouses. In our local greenhouse construction, we include the following components A sanitary pouch. This is for disinfection of hands and feet as […]

Multi-Storey Gardens In Kenya

Grekkon Limited’s climate smart agriculture multi-storey gardens in Kenya are a vertical farming system popular with urban vegetable farmers. Growing herbs on a multi-storey garden in Kenya is now a common practice in limited spaces in densely populated locations. They are defined as climate smart agriculture because they conserve land and water

Multi-storey cropping in a greenhouse

What is a multi-storey garden?

It is a vertical farming method that limited space to create gardens stacked on each other. These vegetable crops (most common for kitchen gardens) provide a fresh supply of vegetables for subsistence or commercial use. Commonly grown crops are;

- Vegetables; kales, spinach, strawberry, coriander, carrot, garlic, leeks, black nightshade, amaranth

- Herbs and spices; rosemary, lemon grass, citronella, and mint

- Fruits; strawberry

A grower will choose to have the multi-storey farming system out in the open, or enclosed in a greenhouse or shade house. This multi-storey cropping is determined by the crop grown, or other factors such as crop destruction by pests or disturbance from pets. A grower will choose to have a shade net or dam liner as the supporting basis of this pyramid farming in Kenya. In this article, we look at the dam liner option

Spinach growing in on a kitchen multi-storey garden made from dam liner material

Our multi-storey garden price is Kes 2,500 a unit for the dam liner material type. This multi-storey garden cost covers all material and labor

How do you make multi-storey gardens in Kenya?

Key attributes of the dam liner material type garden

- Layers. It has 6 layers including the base

- Circumference. The base layer has a 6M circumference

- Layer reduction by height. Each layer is a meter less in circumference as it rises

- Height. Each layer has a height of 0.2M / 20cm

- Material. 0.75mm or 1mm thick HDPE dam liner to hold the soil together. The dam liner is bolted or welded at the joint

Strawberry growing on a multi-storey garden

To reduce soil compaction, and improve soil aeration, we mix soil with manure at a ratio of 2:1. On a space of 2M x 2M, a multi-storey garden will hold 180 to 250 plants. Compare this with a sack/ shade net supported garden that has 100-150 plants. And again with conventional ground farming that has 30-60 plants over the same area. All calculations factor in the walking path

Multi-storey garden materials

- dam liner

- joining clips

- soil

- fertiliser

How to irrigate multi-storey gardens in Kenya

Pre-perforated rip lines or button drippers irrigate these crops. Frequency of irrigation is twice or thrice weekly according to the prevailing weather

Multi-storey gardens in Kenya

FAQs

1. How to prepare a multi storey garden?

As described under the heading How do you make multi-storey gardens in Kenya? above

2. What is the size of a multi-storey garden?

6 square feet

3. What are the advantages of a multi-storey garden?

- It is easy to assemble, and maintain

- It saves on land and water

- They are done over small spaces

- You can grow many typesof vegetable crops on it

4. What are the disdavantages of a multi-storey garden?

- It takes time to design and make

- It requires training to make for the first time

- Expensive to undertake on a large scale. Ideal for small spaces