Solar Water Pump Prices

Solar water pump prices in Kenya by Grekkon Limited are provided based on the pump specs

Our submersible solar water pumps for sale in Kenya are categorised as;

- Motor size. This is given in kilo watts (kW) or horse power (Hp). The motor operates on direct current (DC) generated by the solar panels, or from a battery. The larger the motor size, the more the power a motor consumes, and provides to the pump

- Head. This is the pressure rating provided in meters (M) or bar. It determines how far vertically that pump will push water. The higher the pressure rating, the higher the push. Deep wells use higher pressure rated submersible solar pumps than shallow wells

- Flow rate. It is the volume of water evacuated over a given time unit. This is given as litres per second, or per minute, or as cubic litres per hour. This determines the size of the outlet pipe. A pump that evacuates more water has a larger outlet

Smaller domestic water pumps are portable solar water pumps. It is easy to move them from one shallow well to another. This is not the case for large, permanent, deep well solar water pumps

Solar Water Pump Prices In Kenya

| Model No | Power Hp | Watts | No & Panel Size | Head (M) | Flow rate (liters/ hour) | Price in Kes |

| SP 0.5N | 0.6 | 700 | 300W x 1pc | 40M | 5,800 | 37,120 |

| SP 0.6N | 0.8 | 1,200 | 300W x 2pcs | 60M | 5,800 | 40,215 |

| SP 0.8N | 1.1 | 1,300 | 300W x 3pcs | 70M | 5,800 | 46,400 |

| SP 1.0N | 1.3 | 1,400 | 300W x 3pcs | 80M | 5,800 | 52,600 |

The prices shown above are for solar water pumps for wells less than 100M. Beyond this, we provide specific pumps that match the borehole’s water specs. We install submersible solar water pumps across east Africa for all well sizes. Before an installation is made, a well analysis is conducted to ensure the right solar submersible water pump is provided.

Water Pumps In Kenya

Water pumps in Kenya by Grekkon Limited are varied for different purposes. This provides a wide choice to select from for growers according to irrigation use. Below are water pumps by Grekkon Limited

Water pumps in Kenya

Categorisation

1. By displacement

1.1. Centrifugal pumps work through centrifugal force to drive water that enters the impeller. They use the rotational energy from the spinning impeller to produce hydrodynamic energy

1.2. Positive displacement water pumps use a piston, a diaphragm, or a rotating cog or gear to mechanically move a fixed volume of water through the pump chamber

An electric centrifugal water pump

2. By Location

2.1. Surface pumps suck water through an inlet pipe, then pump it out from an outlet pipe. They are set horizontally on dry surface. Theses are; electric surface pumps including booster pumps, solar surface pumps, diesel and petrol generator water pumps

A diesel water pump

2.2. Submersible water pumps work under water in wells. The size and power depends on the well depth, and discharge rate. They are either solar or electric powered

A submersible solar water pump

3. By power output

3.1. Electric motor powered pumps are either electric (AC current), or solar (DC current) water pumps

An electric surface pump

3.2. Generator powered water pumps are either diesel or petrol types. These are available as high pressure, high volume, low pressure and low volume

A petrol water pump

Water Pumps In Kenya

What To Consider When Buying Your Water Pump

1. The head/ pressure rating

This is the vertical pumping distance in meters or bars. The higher it is, the higher the pressure needed, and the more powerful is the engine or motor. Fuel engine (generator) or electric motor power is horse power (Hp), or in Kilowatts (kW) for the latter

2. The flow rate

This is the amount of water pumped evacuated per unit time. It is in litres per minute or per hour. The higher it is, the larger the water pump inlet and outlet size

For agricultural use, PVC or HDPE water pipes are connected to these pumps. The pipes evacuate water to the crops

3. The power rating

The motor or engine size provided in kilowatts (kW) for the former, and in horse power (Hp) for the latter determines the water pump’s efficiency. The larger the flow rate and the discharge, so will the engine or motor be

Rain Hose Irrigation System

Rain hose irrigation system with nanotechnology punched holes is an affordable irrigation system for overhead irrigation. Rain hose irrigation system uses nano technology to convey water to the plant. It has a series of holes spaced at intervals which sprays water flow by high gravity, or from a water pump is initiated. Our 0.5mm thick, 100M […]

Greenhouse Company In Kenya

Grekkon Limited is the low cost premier greenhouse company in Kenya, known for its galvanised steel tunnel type, and open ventilation type units. We provide affordable greenhouses in Kenya with each unit constructed tailored to the grower’s specifications.

There is a choice of wooden or metallic greenhouses from our choice of low cost greenhouse construction in Kenya. All greenhouse sizes unit have a drip irrigation system installed, with water supplied via a HDPE pipe

How To Construct A Greenhouse

- Assessment of the location. Is it high, mid or low altitude? Tunnel type units are for the highlands and cooler areas. Open ventilation type units for the warm mid to coastal locations

Open ventilation type greenhouse

Tunnel type greenhouses

2. Check the land topography, and water availability. This determines the greenhouse location

3. Understand the target crop type.

This informs us if the unit will have an internal crop support system, and how strong it should be. A strawberry greenhouse will need none, but a tomato or pepper unit will. It advises on the greenhouse net to install. Strawberry and tomato will have different nets on the sides

An insect net on the side to keep away pests

4. Material selection.

- Galvanised steel. Galvanisation keeps it from rust

- UV treated greenhouse polythene with anti-drip properties. UV treatment prevents rapid sun degradation, anti- drip treatment prevents dew formation on the paper. Dew drops falling on the crop are a precursor to fungal diseases. It covers the top and sides of a greenhouse structure to protect the plants within from the elements. It allows in the right spectrum of light for crop growth while filtering away the less needed part of light by the crop. All this creates a an internal environment favourable to plant growth regardless of the external environment. This allows for all year production, improves crop yield and quality

- UV treated insect/ bird net. The former keeps away insect pests, while the latter allows in insects for pollination, but prevents entry of bird pests

- Stainless steel profiles and plastic coated wiggle wires hold the greenhouse paper and netting onto the steel frame

As a greenhouse company in Kenya, the above are the key considerations we make when advising growers on the choice of greenhouse units

Greenhouse Prices In Kenya

1. Metallic

| Greenhouse Type | ||||

| Tunnel Type | Open Ventilated Type | |||

| Greenhouse Size | 15M x 8M | 290,000 | 330,000 | |

| 20M x 8M | 300,000 | 340,000 | ||

| 24M x 8M | 320,000 | 350,000 | ||

| 30M x 8M | 460,000 | 540,000 | ||

| 40M x 8M | 575,000 | 655,000 | ||

| 15M x 16M | 460,000 | 555,000 | ||

| 24M x 16M | 620,000 | 665,000 | ||

| 30M x 16M | 900,000 | 990,000 | ||

| 40M x 16M | 1,100,000 | 1,240,000 | ||

2. Wooden

| Dimensions in meters | Tomato Crop Population | Price in KES |

| 15 x 8 | 600 | KES 140,000 |

| 24 x 8 | 800 | KES 160,000 |

| 30 x 8 | 1,200 | KES 190,000 |

| 30 x 16 | 2,500 | KES 370,000 |

How To Construct Timber Greenhouses

i. Know the crop type to plant. This will guide on the greenhouse design and amount of material to use. For instance, a tomato greenhouse will take more material than one with herbs. This is because tomato will require training, and herbs won’t. It also guides on the greenhouse paper to cover with. You will have more light for fruiting crops like tomato, capsicum, chilli, cucumber, and strawberry, or bi/ multicolored flowers. Have a clear polythene for these. Mono-color flowers will have the yellow polythene cover

ii. Determine the plant population you need. This informs the area of the greenhouse

iii. Once you determine the amount of timber required based on the greenhouse area, treat it. This is to prevent weevils and termites from attacking the timber which reduces it’s lifespan. Do not apply motor oil on the timber as treatment. This is because it will contaminate food crops in the greenhouse

iv. Your construction design is the vented type. This is because the wood cannot be curved to a tunnel type design

v. Cover the roof and side ventilation with an insect net. Select the high density gauge which is effective in keeping away white-flies

vi. Make the beds according to the crop type. Beds are important in managing drainage. For seedling production, set up the tables 1M high

vii. Set up the drip irrigation system on the beds. For seedling production, set up he misting or fogging system above. The misters or foggers are 1M apart

A wooden greenhouse by Grekkon Limited

How to Choose Greenhouse Nets

Greenhouse nets allow for ventilation of the crops, and personnel working in the unit. Below are the consideration made when deciding the choice of greenhouse net to install on the sides

1. Crop type. Some crop types require higher light intensity than others. In this case, a lower shade % net is appropriate for the former. Fruiting crops such as; tomato, strawberry, capsicums, and so on require more light than leafy vegetables. Examples are; cabbage, spinach, collards, kale etc.

2. Crop stage of growth. The shade net in the nursery will block out more heat, than the one for established crops in the field

3. Location of the farm. In the highlands where the heat intensity is less, a lower shade net will protect crops well. In the mid to low altitudes where it’s hotter, a higher shade net works best.

4. Latitude. Countries such as Kenya lie along the equator where solar radiation is high. Your choice of greenhouse net will have higher UV treatment than that of a temperate region

A bird net on a strawberry greenhouse to allow in insects for pollination, while keeping away bird pests

Greenhouse Company In Kenya

FAQs

a. What materials are needed to build a greenhouse?

- UV treated greenhouse polythene

- Steel pipes

- Insect netting

- Profiles and wires

b. Can I grow year-round in a greenhouse?

Yes because the crop is protected from the elements of weather

c. Do greenhouses make money?

Yes they do with a high-value crop

Seedling Trays

Grekkon Limited is a large seedling trays supplier in Kenya. Our black PVC seedling trays for sale in Kenya are for propagation of every vegetable, fruit tree or forestry seedlings or cuttings. These nursery trays work with planting media such as coco peat, peat moss or vermiculite. The soil- less media is sanitised from crop pests and diseases. Every tray has anti-UV treatment to prevent rapid degradation by the sun when placed outdoors. Our nursery trays come in a variety of cell numbers, and sizes. The fewer the cells in a tray, the larger the size, and vice versa. The price of nursery trays when paid for is insignificant when put against the immense benefits these trays provide. Grekkon Limited’s seedling trays are re-usable over many seasons of seedlings or cuttings growth.

Seedling Trays Prices In Kenya

| Cell Number | Cell Dimensions (L x W x D) | Price |

| 28 | 75 | |

| 50 | 75 | |

| 66 | 75 | |

| 128 | 75 | |

| 160 | 75 | |

| 200 | 75 | |

| 204 | 75 | |

| 288 | 75 |

Advantages of using trays for seedlings

- Reduces incidences of damping off caused by overcrowding and non treated soil

- You are assured of good germination compared to soil

- There is much improved root development and reduces incidences of transplanting shock

- Crops grown from germination trays mature faster as they quickly establish once transplanted

- Uniform harvesting as compared to those raised directly in the soil.

- They can easily be transported with zero damage

Steps to plant seeds in trays

- Add the planting media up to about 80% of the cell volume

- Place the seed a single seed at the top of this media

- Do this for all cells in the tray

- Add another layer of the planting media to fill up the small space left. This will cover the seed

- Add water

- Place the planting tray in a warm place, with ample light, and free of pests

- Place a label showing; the crop type, date of planting, expected date of transplanting

Do not stack the trays on top of each other

Grekkon Limited’s nursery trays are used by small, medium, and large scale farmers for high value crops. They are available in all our outlets countrywide. The company agronomy team trains new farmers on ;

- selection by crop type or stage of transplanting

- planting media

- re-use

- placement in the greenhouse, shade net or other shelter

Proper storage of seedling trays after use ensures their longevity. Stacking them together in a sheltered place is most recommended. Clean them in a disinfectant after use, just before storage. This treatment keeps them sanitised and free of any pests or disease causing pathogens

Germination trays for sale;

- Tomato seedling trays

A farmer growing tomato for the greenhouse will use the 200 or 204 cell trays. These tomatoes will be small in size during transplanting to this protected environment. A farmer growing outdoor tomato will use the 128 – 160 hole seedling trays. These tomato seedlings will be bigger and stronger to withstand harsh climatic conditions in the field.

- Onion seedling trays.

Growers doing onions will use the 288 cell seedling trays.

- Different seedling production in trays.

Onion has tiny seedlings which at maturity fit well in small cells. Tomato, peppers, cabbage, and chilies will use larger cells seedling trays.

- Seedlings production in trays.

Apply the coco peat planting media on all cells up to 3/4. Place the tiny seeds individually in each cell, then cover with the coco peat planting media

Germination trays with coco peat ready for planting

Seedling Trays

FAQs

i. What are seedling tray prices?

Our UV-treated PVC seedling trays cost Kes 90 apiece for all cell numbers. These seedlings trays prices in Kenya are retail, and a discount is offered for bulk buyers

ii. What can I use for seed trays?

Vegetable seed germination, fruit tree or forestry seedlings growth, and silkworm growing

iii. How do you use germination trays?

In an era when farmers have graduated to high-value hybrid vegetable seeds;

- germination trays make it possible to account for each seedling, the reason that every seed is placed manually one by one

- this makes it easy to count actual germination and seedling survivals

- the seedlings have less pest and disease infestation because the trays are used with sanitized growing media

- at transplanting, the growing media covers the root system which prevents transplanting shock in the field or greenhouse

- transplanting shock slows down crop growth and delays maturity

iv. When should I transplant my seed trays?

When the crop has been hardened enough to withstand open field, or greenhouse conditions

v. How do you use seed trays?

Add treated planting media in each cell, then sow one seed per cell. Water it to keep it moist till transplanting

vi. How deep should a seed tray be?

Not less than 5cm for vegetable crops, much deeper for tree crops like forestry and fruit

Grekkon Limited’s agronomists guide every farmer during procurement on the most appropriate tray to use.

Low Cost Greenhouses In Kenya

Our low cost greenhouses in Kenya are either wooden or metallic in structure, vented or tunnel in shape. Internally, they will or will not have crop support systems, and the steel will be galvanised or painted with a protective coat

These low cost greenhouse construction in Kenya attributes are explained in detail below:

- Greenhouse size; the larger it, the lower the unit area cost

- Greenhouse material type. Wooden greenhouses are cheaper than steel frame greenhouses, because steel is more costly. However, they have a shorter lifespan

A low cost wooden greenhouse in Kenya by Grekkon Limited

3. Greenhouse design. Tunnel type greenhouses are lessor priced than vented types. The former are for cool highland locations so that they retain heat, while the latter are for hot locations for less build up of heat

Tunnel type greenhouse

A vented type greenhouse structure

4. Greenhouse use. Is it for flowers, vegetables, strawberry, herbs and spices or seedlings production? This influences the infrastructure set up within the greenhouse. Crops that do not require a greenhouse with an internal crop support system such as; strawberry, herbs, and spices have lower greenhouse construction costs

Seedlings production in a greenhouse

Roses production in greenhouse

5. Steel treatment type. To lower the cost of the greenhouse structure, some growers opt for steel painted with an aluminum or zinc coating. This is less costly than the zinc galvanised steel. However, the paint wears out over time and the greenhouse frame is repainted to prevent rust

As the leading greenhouse company in Kenya, we utilise local greenhouse construction techniques. Our low cost greenhouses in Kenya are for such crops as; roses, carnations, tomato, capsicums, strawberry, and assorted herbs and spices

I. Low Cost Greenhouses in Kenya

1. Greenhouse price in Kenya: Tabulation of steel types

| Greenhouse Type | ||||

| Tunnel Type | Open Ventilated Type | |||

| Greenhouse Sizes | 15M x 8M | 290,000 | 330,000 | |

| 20M x 8M | 300,000 | 340,000 | ||

| 24M x 8M | 320,000 | 350,000 | ||

| 30M x 8M | 460,000 | 540,000 | ||

| 40M x 8M | 575,000 | 655,000 | ||

| 15M x 16M | 460,000 | 555,000 | ||

| 24M x 16M | 620,000 | 665,000 | ||

| 30M x 16M | 900,000 | 990,000 | ||

| 40M x 16M | 1,100,000 | 1,240,000 | ||

2. Low cost wooden greenhouse prices

| Greenhouse sizes | Tomato Crop Population | Price in KES |

| 15 x 8 | 600 | KES 155,000 |

| 24 x 8 | 800 | KES 200,000 |

| 30 x 8 | 1,200 | KES 250,000 |

| 30 x 16 | 2,500 | KES 400,000 |

II. How much does it cost to install a greenhouse in Kenya?

Every tabulated greenhouse price in Kenya above by Grekkon Limited covers both the material and labor cost of greenhouse construction or installation

III. How profitable is greenhouse farming in Kenya?

Every low cost greenhouse for sale in Kenya procured for crop production is a significant investment for the farmer. To optimise revenue and ensure profitability, a grower will adhere to the following

1. Conduct a complete soil test. This will guide the farmer on 2 things

- the right crop nutrition regime

- and the suitability of that soil to establish a greenhouse in regards to any existing soil pests and diseases

2.Choose the right seed. Whatever crop you choose to grow, select the best yielding greenhouse varieties

3. Crop type. The value of the final produce according to market preference

4. Right greenhouse structure. This will be determined by the greenhouse location. Is it a vented or tunnel design?

5. Proper greenhouse polythene color and specs. Follow this guideline

- Yellow polythene is for mono color flowers or none fruiting crops which produce well under lower light intensity

- Clear polythene is for bi or multi colored flowers and any fruiting crop which requires higher light intensity for photosynthesis

- It will have UV treatment to last for long, and to block strong UV rays from reaching the crop

- It will be treated for anti-drip qualities. This prevents dew from forming on the paper and dripping on the crop causing disease infection

6. Irrigation management. As an irrigation company, we provide a detailed irrigation regime tailored to the crop type and growth stage

7. Disease and pest management.

- Have a sanitary pouch at the entrance to sanitize feet, and hands

- Limit access to the greenhouse to a few people

- Daily scouting for pests and diseases

- Have a scheduled pest and disease spray program

Dam Liners Prices in Kenya

Dam liners prices in Kenya for irrigation by Grekkon Limited vary annually by raw material cost. These dam liners will be installed on reservoirs, or water tanks. Their purpose is to prevent water loss through absorption by the soil surface.

Our dam liner material is high density UV treated geomembrane. UV treatment is to slow down degradation by the sun during external use. Grekkon Limited’s dam liners for sale in Kenya are categorised according to thickness

A small water reservoir for vegetable irrigation with a 0.5mm dam liner installed by Grekkon Limited in Emabungo area, Vihiga county. Notice the fence around it fo safety reasons

Dam Liner Prices in Kenya

| Liner Thickness | Material Cost In Kes | Welding Cost In Kes | Installation Cost In Kes | AMOUNT In Kes |

| 0.5mm | 220 | 30 | 30 | 280 |

| 0.75mm | 300 | 30 | 30 | 360 |

| 1mm | 380 | 30 | 30 | 440 |

Introducing the 1.5mm dam liner for Kes 780/M square all inclusive

Notes

- Welding cost applies when the liner required is wider than 8M

- Installation cost is charged when a Grekkon Limited technician installs the liner

Dam Liners Material Thickness Application

- 0.5mm liners are for smooth surfaces without stones or rocks. It will work on a surface with murram. The life span is 8 to 12 years

- 0.75mm liners are for rough surfaces with some stones or rocks. The lifespan is 15 to 20 years

- 1mm liners are for stony or rocky surfaces. The lifespan is over 25 years

The choice of liner thickness is a factor of the liner size. A liner holding 10,000 cubic is thicker than one holding 500 cubic

Dam Liners Prices In Kenya

Processes Every Grower Should Know

I. How to calculate your dam liner size

- Measure your reservoir length (L), width (W) and depth (D) in meters

- Apply the formula; (L+2D+2) + (W+2D+2). This converts your 3D measurement to 2D

II. Steps to install your dam liner

- Clean up your reservoir floor to remove any debris that will perforate the liner

- Lay your liner at the center on the floor of the reservoir

- Spread it out to cover the entire floor, and the walls

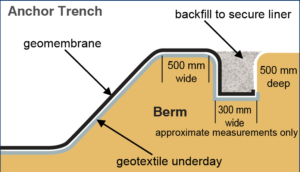

- Make a trench 1M away from the edge of the reservoir, all around it

- The trench measure 30cm/ 1ft deep by 30cm/ 1ft wide

- Tuck your liner in this trench, then cover it with lots of soil

III. How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

IV. How to Harvest Water Using Dam Liners

Factors to consider that will affect your dam liners prices in Kenya

a. Land size

The amount of water required for half an acre is less than that needed for 20 acres. The latter will harvest more water to irrigate the greater acreage, and the former will have less water harvested. The bigger the volume of water reserved, the larger the dam liner size

b. Location

The amount of rain fall is different in every climatic zone. Growers in the cool wet highlands have just a few dry months in the year, while farmers in the dry zones have more dry months than wet. In regions where the interval between rains is long, larger reservoirs are built for the same acreage as that in the cool wet location. Again, dry locations have very high water loss through evaporation. In this case, it is advised to set up a shade net over the water reservoir to manage this water loss

c. Ground Elevation

The farm gradient determines the location of the water pan. Some choose to have it at the lowest part so as to capture run-off water. If it is for crop irrigation, this water is either pumped uphill to a tank from where it flows back by gravity to the crop. Or it is pumped directly to the crop from the water reservoir. Others choose to locate the water pan on the highest point of the farm so that the water, through gravity flows out to the crop. In this case, the farmer does not retain run-off rain water from the farm. On a flat terrain, irrigation water is physically pumped out to either a high storage tank for onward gravity flow to the crop. Or directly to the crop

A low reservoir that collects run-off rain water

d. Farming System

The size of the water pan will differ for irrigation, compared with aquaculture or livestock production

e. Crop Type

Some crops are more water demanding such as leafy vegetables, than others such as herbs. Then some crops like onion are densely spaced while others are like avocado are sparsely populated in the farm. This will determine the water requirement

f. Irrigation System

Every irrigation system has it’s own unique water use. Drip irrigation conserves water while overhead irrigation through sprinklers or rain hose kits spends huge water volumes

g. Surface Texture

The surface texture of the water pan determines the dam liner thickness to install. For a smooth surface, a 0.5mm dam liner is ok. Where the surface is stony or rocky, then the 0.75mm or 1mm dam line is better

How To Install Dam Liners In Kenya

What is dam lining?

It is the lining of the floor and walls of a water pan with a geomembrane material. This material is impermeable and holds the water above it for agricultural use

To cover a reservoir with a dam liner is a simple yet complicated task. Proper dam liner installation in Kenya will guarantee good water collection for irrigation and domestic use. It requires proper coordination so as to achieve the intended objective. Before installation, one must learn how to measure a dam liner so as to determine the area of material needed for the water pan or tank. Grekkon Limited is your number one company in supply and installation of dam liners in Kenya

How do you measure a dam liner?

- Measure the length of the water reservoir

- Measure the width of the water reservoir

- Determine the depth from the center-most part of the water pan which is deemed as the deepest part

- Apply this formula (length+2 depth+2 meters) X (width+2 depth+2meters). The additional 2 meters in each set are for tucking the liner. The dam liner tucking distance from the edges is taken as 1M all around te water pan

Steps on How to Install Dam liners in Kenya

Water Pan Excavation

This is the first step and usually takes the longest time. Excavation is manual with handtools, or with a machine. Most common machines for dam excavation are backhoe loaders, bull-dozers and caterpillars. At excavation, the side walls are inclined at an angle to prevent collapse of the dam.

Read Also: How to join dam liners and Quality dam liners in Kenya by Grekkon Limited

Smoothening Of The Water Pan

This is to remove any sharp objects that damage the dam liner. Pour in water on the floor and sides to soften it.

Trench Making

Trenches are dug round the dam where the dam liner will be installed. The size of the trench will depend on the size of the dam and the dam liner thickness. The most popular trench sizes are 1ft deep by 1ft wide and 1.5ft deep by 1.5ft wide.

Observe the trench made around the water pan. it is 1M from the edges of the water pan, and this is where the dam liner will be tucked

How To Install Dam Liners In Kenya

- Place the dam liner in the reservoir. This way, it takes the shape of the reservoir

- The liner must have an allowance for overlap. Bury the overlap in the trench, then cover with soil for a smooth finish. The trench dimensions will be 0.45M to 0.6M deep, and 0.3M wide. Several casual labourers make the process as smooth as possible. Where no trench has been made, support the dam liner with sand/ soil bags to achieve the same result

- Install an inlet and an over flow. The inlet is a pipe from a river, borehole or from the roof gutter section. Dams that trap run off water have a silt trap with several chambers to trap stones, mud and other debris.

How To Weld Dam Liners

- This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit. The welded joints must be leak free for the dam liner to work effectively in the tank or water pan. Lined water pans are popular as water storage units for agricultural field crops irrigation in a country that has just one or two rainy seasons

Coco Peat Price In Kenya

Grekkon Limited’s coco peat price in Kenya is per kg of dry material. As the largest coco peat supplier in Kenya, we keep the moisture level to the lowest level for greater value. The fiber content varies according to the growers need because we tailor this. Our coco peat for sale in Kenya is available from 5kg bags, and our cost of coco peat in Kenya is as wholesale or retail

Advantages of coco noir

- It is easy to make

- When well treated, it has near zero diseases and pests

- It is easily available

- Seedlings established in, or plants grown hydroponically in coco peat grow 50% faster than in soil. This is because it is highly porous allowing for vigorous root growth and rot air supply

- It has a high water holding capacity

- It is environmentally friendly because it is a 100% natural product

- Coco peat neutralises soil acidity

Coco peat growing medium in a hydroponic unit

Disadvantages of coco noir

- It is a more expensive option than soil

- If not well treated, it can harbor pests and diseases

- Getting the right EC and moisture levels is difficult

- It is rich in sodium and potassium salts

- It requires treatment

How to make coco peat soil

- Collect coconut husks (mature green coloured ones, not the brown dry shells)

- Cut them up to smaller pieces

- Clean them in water to remove dirt and other debris

- Sun dry them

- Run them in the grinding machine

- Sieve the product to separate the coco peat from the fibers. The choice of sieve depends on the amount of fiber needed in the final product

We process our coco peat in Kilifi and Kwale counties, empowering hundreds of coconut farmers who supply our processing plant with raw material. Our production process provides the best coco peat for sale in Kenya. The final material is applied my hundreds of farmers for production of seedlings and mature crop growing. The table below provides details of our final coco peat material after processing

Coco Peat Price In Kenya:

Cost of Coco Peat and Material Specs Tabulation

| 1kg of coco peat (loose) | Kes 80 |

| PH | 6.3 – 6.7 |

| Electrical conductivity (EC) | 1.6 – 2.0 |

| Expansion ratio | 2.5 – 3 |

| Moisture content | <5% |

| Compression volume | 28L |

| Fiber content* | <3% |

| Sand content | <1% |

A 5kg block of treated coco peat is Kes 600

* the fiber content is tailored to the growers need. Seedling nurseries require <3%, while potted plants or a growing crop will do up-to 30%

Our coco peat price is discounted for large volume purchases

High fiber

Low fiber

Coco Peat Price In Kenya

FAQs

I. How do you treat coco peat before planting?

Step 1.

Soak it overnight in water. Unwashed coco peat has high levels of sodium, potassium and chloride which make it highly saline. High salinity = high pH (>7.0). High salinity locks up many nutrients making them unavailable to the crop

Step 2.

Dissolve 2.5g of calcium nitrate for every liter of water. This is arrest excess sodium or potassium chloride salts in it, and to increase nitrogen. Again, plants grown in coco peat tend to become deficient in calcium or magnesium as they grow

Step 3.

Rinse it in running water until the brown coloration disappears

In nurseries, coco peat is input in seedling trays, while in greenhouses, this is in troughs.

Seedlings germinated on low fiber

A crop grown on high fiber coco peat

II. How much does 1kg coco peat expand?

1kg of coco peat expands to 5kgs

III. Can I plant directly in coco peat?

No because it does not have nutrients for the crop. This is only possible under hydroponic growing where nutrients are supplied to the crop often. Coco peat alone is used for germinating seeds

IV. What are the disadvantages of coco peat?

- it is high in potassium

- if not properly sanitised, it will harbour pests and diseases

- it is more costly to germinate wit than soil

- during processing, it is difficult to attain the right pH and moisture content

V. How long can coco peat last?

Coco peat begins to break down after 10 years. It is therefore be reused over 4 years, because it resists accumulation of crop harmful bacteria and fungi

VI. Can we mix coco peat and soil?

Yes, at a ratio of 3 parts of soil to 1 part of coco peat. This is done as a soil amendment measure; to loosen the top soil

VII. Can seeds germinate in coco peat only?

Yes, coco peat is perfect medium for seeds germination. This is because it re-wets very easily

Soil mixing with coco peat. Observe a soil to coco peat ratio of 3:1

VIII. How much water do you put in coco peat only?

Apply water at a ration of 3.5litres for every 5kgs of coco peat

IX. Can I use coco peat only instead of soil?

Yes in hydroponic crop production. Crops under hydroponic production grow 50% faster than they would in soil

X. Which plants grow well in coco peat?

Potted plants, and ornamentals such as ferns, cactus, orchids, bromeliads, anthuriams and others

XI. Do you need to wash coco peat?

Yes to remove excess salts. Clean it in running water until the water is clear

XII. Is growing in coco peat better than in soil?

It is better, but expensive because nutrients and water have to be added frequently. Coco peat has little and few nutrients of its own, and it dries out fast. Hydroponic plants grown with coco peat grow faster, they have higher yields, they enjoy a neutral pH, and their roots extend easily

XIII. How often do you water coco peat?

Every 4 to 5 days

XIV. What is the best fertiliser for coco peat?

Granular NPK fertiliser with a ratio of 2-1-1 is best. Apply both fast and slow nitrogen releasing fertilisers

Pond Liner Calculator

In this pond liner calculator article, we answer the following frequently asked questions

1. How is a dam liner calculated?

The formulae adopted depends the shape of the water pan. The water reservoir’s dam liner is calculated differently for a circular or oval water pan vis a vis that of a square/ rectangular one. Similarly, a square water tank has a different formulae from a circular one. A water pan with slanting edges has a different formulae from that with straight edges. Whether the water reservoir or tank is for irrigation, domestic or industrial application, the formulae is the same

I. Square/ rectangular water reservoir or tank pond liner calculator

a. Square/ rectangular pond liner calculator for straight edges: Total length in meters: (length + 2depth + 2meters). Total width in meters: (width + 2depth +2meters). The additional 2meters on each side are for the overlap which is tucked in a trench for water reservoirs. For tanks, it’ll be 0.5M. Multiplying the total length with the total width gives the pond liner area in meters

Pond liner installation in a water reservoir with straight edges

Tucking is in a trench all around the water pan

How to trench and tuck your pond liner

b. Square/ rectangular pond liner calculator for slanted edges: Total length in meters: (base length + 2slanting depth + 2meters). Total width in meters: (base width + 2slanting depth +2meters). Multiplying the total length with the total width gives the pond liner area in meters

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

II. Circular pond liner calculator

Diameter + (2height/ depth) + (1meter). The 1meter is the external allowance that goes outside the tank as shown in the image below

A liner in a cylindrical tank

2. How do I calculate how much pond liner I need?

The size of the pond liner is according to the water pan or water tank area. The size of the water pan or tank is by volume, shown as; length by width by depth/ height. The liner size is by area, shown as; length by width. For this conversion, the formulas shown above work

The larger the water pan or tank, the larger the pond liner required