How To Install Dam Liners In Kenya

What is dam lining?

It is the lining of the floor and walls of a water pan with a geomembrane material. This material is impermeable and holds the water above it for agricultural use

To cover a reservoir with a dam liner is a simple yet complicated task. Proper dam liner installation in Kenya will guarantee good water collection for irrigation and domestic use. It requires proper coordination so as to achieve the intended objective. Before installation, one must learn how to measure a dam liner so as to determine the area of material needed for the water pan or tank. Grekkon Limited is your number one company in supply and installation of dam liners in Kenya

How do you measure a dam liner?

- Measure the length of the water reservoir

- Measure the width of the water reservoir

- Determine the depth from the center-most part of the water pan which is deemed as the deepest part

- Apply this formula (length+2 depth+2 meters) X (width+2 depth+2meters). The additional 2 meters in each set are for tucking the liner. The dam liner tucking distance from the edges is taken as 1M all around te water pan

Steps on How to Install Dam liners in Kenya

Water Pan Excavation

This is the first step and usually takes the longest time. Excavation is manual with handtools, or with a machine. Most common machines for dam excavation are backhoe loaders, bull-dozers and caterpillars. At excavation, the side walls are inclined at an angle to prevent collapse of the dam.

Read Also: How to join dam liners and Quality dam liners in Kenya by Grekkon Limited

Smoothening Of The Water Pan

This is to remove any sharp objects that damage the dam liner. Pour in water on the floor and sides to soften it.

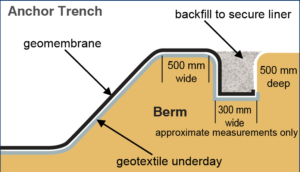

Trench Making

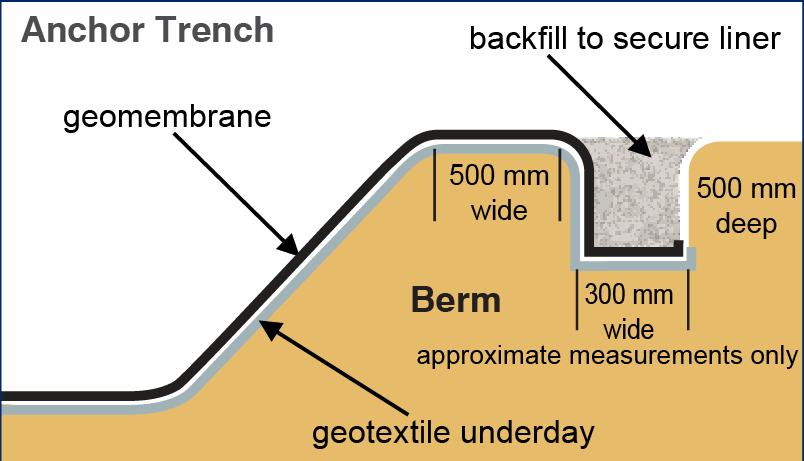

Trenches are dug round the dam where the dam liner will be installed. The size of the trench will depend on the size of the dam and the dam liner thickness. The most popular trench sizes are 1ft deep by 1ft wide and 1.5ft deep by 1.5ft wide.

Observe the trench made around the water pan. it is 1M from the edges of the water pan, and this is where the dam liner will be tucked

How To Install Dam Liners In Kenya

- Place the dam liner in the reservoir. This way, it takes the shape of the reservoir

- The liner must have an allowance for overlap. Bury the overlap in the trench, then cover with soil for a smooth finish. The trench dimensions will be 0.45M to 0.6M deep, and 0.3M wide. Several casual labourers make the process as smooth as possible. Where no trench has been made, support the dam liner with sand/ soil bags to achieve the same result

- Install an inlet and an over flow. The inlet is a pipe from a river, borehole or from the roof gutter section. Dams that trap run off water have a silt trap with several chambers to trap stones, mud and other debris.

How To Weld Dam Liners

- This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit. The welded joints must be leak free for the dam liner to work effectively in the tank or water pan. Lined water pans are popular as water storage units for agricultural field crops irrigation in a country that has just one or two rainy seasons

Coco Peat Price In Kenya

Grekkon Limited’s coco peat price in Kenya is per kg of dry material. As the largest coco peat supplier in Kenya, we keep the moisture level to the lowest level for greater value. The fiber content varies according to the growers need because we tailor this. Our coco peat for sale in Kenya is available from 5kg bags, and our cost of coco peat in Kenya is as wholesale or retail

Advantages of coco noir

- It is easy to make

- When well treated, it has near zero diseases and pests

- It is easily available

- Seedlings established in, or plants grown hydroponically in coco peat grow 50% faster than in soil. This is because it is highly porous allowing for vigorous root growth and rot air supply

- It has a high water holding capacity

- It is environmentally friendly because it is a 100% natural product

- Coco peat neutralises soil acidity

Coco peat growing medium in a hydroponic unit

Disadvantages of coco noir

- It is a more expensive option than soil

- If not well treated, it can harbor pests and diseases

- Getting the right EC and moisture levels is difficult

- It is rich in sodium and potassium salts

- It requires treatment

How to make coco peat soil

- Collect coconut husks (mature green coloured ones, not the brown dry shells)

- Cut them up to smaller pieces

- Clean them in water to remove dirt and other debris

- Sun dry them

- Run them in the grinding machine

- Sieve the product to separate the coco peat from the fibers. The choice of sieve depends on the amount of fiber needed in the final product

We process our coco peat in Kilifi and Kwale counties, empowering hundreds of coconut farmers who supply our processing plant with raw material. Our production process provides the best coco peat for sale in Kenya. The final material is applied my hundreds of farmers for production of seedlings and mature crop growing. The table below provides details of our final coco peat material after processing

Coco Peat Price In Kenya:

Cost of Coco Peat and Material Specs Tabulation

| 1kg of coco peat (loose) | Kes 80 |

| PH | 6.3 – 6.7 |

| Electrical conductivity (EC) | 1.6 – 2.0 |

| Expansion ratio | 2.5 – 3 |

| Moisture content | <5% |

| Compression volume | 28L |

| Fiber content* | <3% |

| Sand content | <1% |

A 5kg block of treated coco peat is Kes 600

* the fiber content is tailored to the growers need. Seedling nurseries require <3%, while potted plants or a growing crop will do up-to 30%

Our coco peat price is discounted for large volume purchases

High fiber

Low fiber

Coco Peat Price In Kenya

FAQs

I. How do you treat coco peat before planting?

Step 1.

Soak it overnight in water. Unwashed coco peat has high levels of sodium, potassium and chloride which make it highly saline. High salinity = high pH (>7.0). High salinity locks up many nutrients making them unavailable to the crop

Step 2.

Dissolve 2.5g of calcium nitrate for every liter of water. This is arrest excess sodium or potassium chloride salts in it, and to increase nitrogen. Again, plants grown in coco peat tend to become deficient in calcium or magnesium as they grow

Step 3.

Rinse it in running water until the brown coloration disappears

In nurseries, coco peat is input in seedling trays, while in greenhouses, this is in troughs.

Seedlings germinated on low fiber

A crop grown on high fiber coco peat

II. How much does 1kg coco peat expand?

1kg of coco peat expands to 5kgs

III. Can I plant directly in coco peat?

No because it does not have nutrients for the crop. This is only possible under hydroponic growing where nutrients are supplied to the crop often. Coco peat alone is used for germinating seeds

IV. What are the disadvantages of coco peat?

- it is high in potassium

- if not properly sanitised, it will harbour pests and diseases

- it is more costly to germinate wit than soil

- during processing, it is difficult to attain the right pH and moisture content

V. How long can coco peat last?

Coco peat begins to break down after 10 years. It is therefore be reused over 4 years, because it resists accumulation of crop harmful bacteria and fungi

VI. Can we mix coco peat and soil?

Yes, at a ratio of 3 parts of soil to 1 part of coco peat. This is done as a soil amendment measure; to loosen the top soil

VII. Can seeds germinate in coco peat only?

Yes, coco peat is perfect medium for seeds germination. This is because it re-wets very easily

Soil mixing with coco peat. Observe a soil to coco peat ratio of 3:1

VIII. How much water do you put in coco peat only?

Apply water at a ration of 3.5litres for every 5kgs of coco peat

IX. Can I use coco peat only instead of soil?

Yes in hydroponic crop production. Crops under hydroponic production grow 50% faster than they would in soil

X. Which plants grow well in coco peat?

Potted plants, and ornamentals such as ferns, cactus, orchids, bromeliads, anthuriams and others

XI. Do you need to wash coco peat?

Yes to remove excess salts. Clean it in running water until the water is clear

XII. Is growing in coco peat better than in soil?

It is better, but expensive because nutrients and water have to be added frequently. Coco peat has little and few nutrients of its own, and it dries out fast. Hydroponic plants grown with coco peat grow faster, they have higher yields, they enjoy a neutral pH, and their roots extend easily

XIII. How often do you water coco peat?

Every 4 to 5 days

XIV. What is the best fertiliser for coco peat?

Granular NPK fertiliser with a ratio of 2-1-1 is best. Apply both fast and slow nitrogen releasing fertilisers

Pond Liner Calculator

In this pond liner calculator article, we answer the following frequently asked questions

1. How is a dam liner calculated?

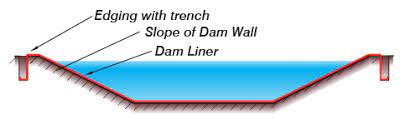

The formulae adopted depends the shape of the water pan. The water reservoir’s dam liner is calculated differently for a circular or oval water pan vis a vis that of a square/ rectangular one. Similarly, a square water tank has a different formulae from a circular one. A water pan with slanting edges has a different formulae from that with straight edges. Whether the water reservoir or tank is for irrigation, domestic or industrial application, the formulae is the same

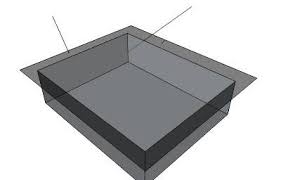

I. Square/ rectangular water reservoir or tank pond liner calculator

a. Square/ rectangular pond liner calculator for straight edges: Total length in meters: (length + 2depth + 2meters). Total width in meters: (width + 2depth +2meters). The additional 2meters on each side are for the overlap which is tucked in a trench for water reservoirs. For tanks, it’ll be 0.5M. Multiplying the total length with the total width gives the pond liner area in meters

Pond liner installation in a water reservoir with straight edges

Tucking is in a trench all around the water pan

How to trench and tuck your pond liner

b. Square/ rectangular pond liner calculator for slanted edges: Total length in meters: (base length + 2slanting depth + 2meters). Total width in meters: (base width + 2slanting depth +2meters). Multiplying the total length with the total width gives the pond liner area in meters

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

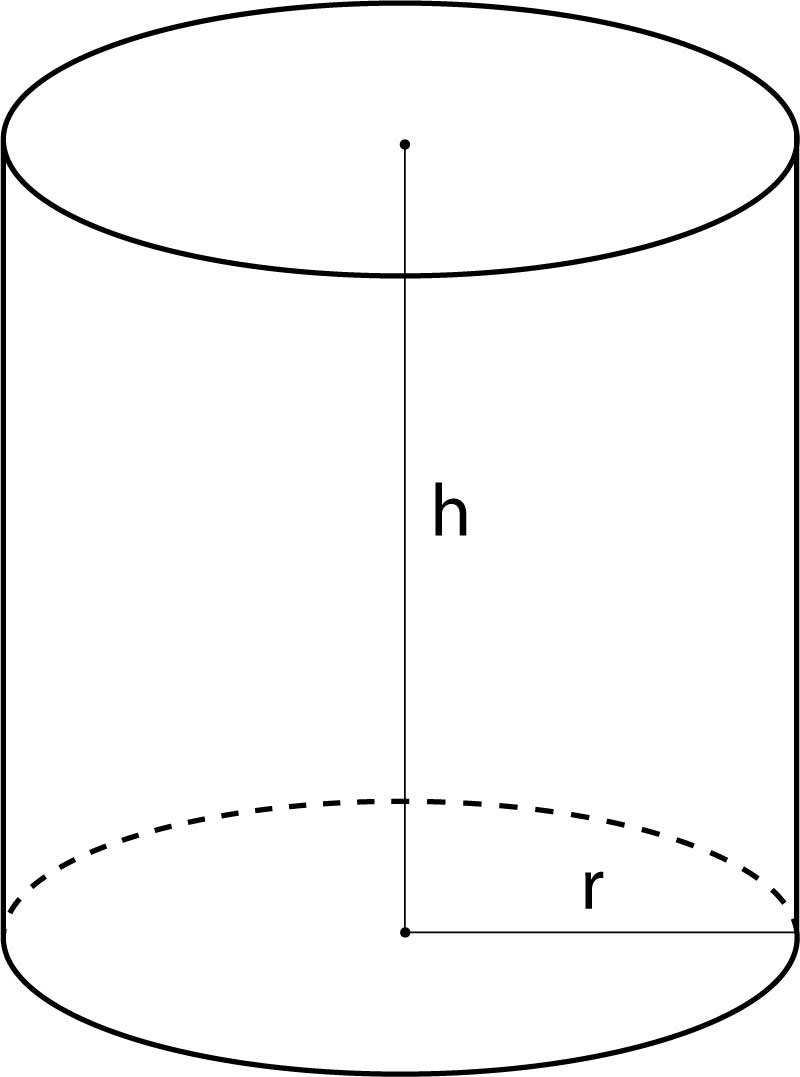

II. Circular pond liner calculator

Diameter + (2height/ depth) + (1meter). The 1meter is the external allowance that goes outside the tank as shown in the image below

A liner in a cylindrical tank

2. How do I calculate how much pond liner I need?

The size of the pond liner is according to the water pan or water tank area. The size of the water pan or tank is by volume, shown as; length by width by depth/ height. The liner size is by area, shown as; length by width. For this conversion, the formulas shown above work

The larger the water pan or tank, the larger the pond liner required

Dam Liner Company In Kenya

Grekkon Limited is the foremost dam liner company in Kenya. From material selection, to welding and installation, our professional teams train growers on all these aspects. It ensures that they make the right choice and why

This is according to the size and nature of their irrigation water reservoirs and tanks. These dam liners in Kenya are UV treated, HDPE geomembrane material in varying thicknesses and weights as tabulated below

| Liner Thickness | Liner Weight/ M SQ |

| 0.5mm | 460g |

| 0.75mm | 880g |

| 1mm | 910g |

The UV treatment reduces radiation damage which is high in tropical countries

A roll of 0.75mm dam liner

Dam Liner Prices In Kenya

Our dam liner cost in Kenya is broken down into; material, welding, and installation. Once a grower procures a dam liner, s/he will have it welded if the width exceeds 8M. If the farmer chooses for us to install, then the cost of installation applies.

| Liner Thickness | Material Cost (KES) | Welding Cost (KES) | Installation Cost (KES) | AMOUNT (KES) |

| 0.5mm | 220 | 25 | 25 | 270 |

| 0.75mm | 300 | 25 | 25 | 350 |

| 1mm | 380 | 25 | 25 | 430 |

How Are Dam Liners Calculated?

Before determining the dam liner size, one must understand the size of the reservoir or tank. This is by measuring the length, width, and depth/ height (for rectangular or square shaped reservoirs/ tanks). For circular or cylindrical tanks/ reservoirs, measure the diameter, and the depth/ height. The reason this is key is because our dam liner material comes in rolls. To make out the shape of the water pan or tank, the dam liner is cut in large bits from the roll and joined together. This is to create the 2 dimension size of the water reservoir or tank. For example; if the width of the dam liner on the roll is 8M, and the water pan requires a width of 15M. Then 2 pieces, one measuring 8M and another 7M in width from the roll are cut and joined to create the 15M width

How Do I Calculate How Much Dam Liner I Need?

The dam liner calculator is adapted to the shape of the irrigation water reservoir as illustated in the 3 different shapes below

- Sloped sides reservoir

The slope of the dam wall is shown as slanting length (SL) or slanting width (SW) in the dam liner calculator tabulation shown later in this page

2. Cylindrical circular tanks

3. Straight side reservoirs

Pond Liner Calculator: Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

Dam Liner Calculator

How much overhang should a pond liner have?

An overhang is the extra liner material that holds the main liner in the reservoir or tank. This excess material is held against the external wall of the tank, or tucked in a trench all around the reservoir to support the dam liner in place. It is covered with soil or stones in the trench. Another alternative to trenching is to lay sand bags on it. The weight of the sand bags holds the dam liner in place

After excavation, it is necessary to compress the mould of soil roundabout the water pan before making a trench

See below

Dam Liner Installation

Our dam liner rolls are 8M wide. So for any width beyond this, the additional size has to be welded on. Welding is carried out fully in the ware house for small liners, and partly in the field for large liners. This is to reduce bulkiness during transportation to site

When installing a dam liner in a reservoir, trench round about the reservoir. This anchor trench is where the liner will be tucked for support

The video below shows a farmer in Nandi county recounting the benefits he has received 2 years later after having his dam liner installed by Grekkon Limited

How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

Both equipment run on electric power. In off grid electricity locations, Grekkon Limited provides a generator to power the heat gun or wedge welding machine

Dam Liner Company In Kenya: Summary

Every dam liner size is available from our outlets countrywide. Besides supplying and installing liners, our technical team advises growers on;

- The right size of reservoir for a particular acreage

- How to properly excavate your reservoir

- How to select the right dam liner according to ; the reservoir size, surface texture, and one’s budget

Water Sprinklers

Water sprinklers for sale in Kenya by Grekkon Limited are categorised by size. The sprinkler size determines the place of use, as a result of the unit amount of water it gives. Water sprinklers in Kenya are either plastic or metallic. This affects the price and longevity, but not the water volume.

1. Garden Sprinklers

These have an inlet diameter of 1″, 3/4″ and 1/2″. Garden sprinklers have low water volume, and are for home gardening. This includes; kitchen gardens, small scale farms, lawns, hedges, and flower beds. Their irrigation diameter is 3M to 14M according to inlet size and make.

Examples

1.1. Butterfly sprinklers

1.2. Mega net sprinklers

1.3. Impact sprinklers

Metallic impact sprinklers

Plastic impact sprinklers

1.4. Pop up sprinklers

1.5. Lawn sprinkler

1.6. Sprinkler jet micro sprinkler

Garden Water Sprinklers Prices in Kenya

A commonly asked question; How much does a sprinkler cost in Kenya?

The table below answers this

| Type | Inlet Diameter | Max Spray Diameter | Min Head (Pressure Rating) | Max Flow Rate | Price in Kes |

| Impact Sprinklers | 1″ | 12M | 10M | 3M3/ Hr | 1,250 |

| 3/4″ | 7.5M | 10M | 2M3/ Hr | 750 | |

| 1/2″ | 5M | 10M | 1.5M3/ Hr | 450 | |

| Butterfly & Micro Sprinklers | 1/2″ | 3M | 3M | 0.1M3/ Hr | 150 |

| Mega net Sprinklers | 3/4″ | 10M | 20M | 0.3M3/ Hr | 250 |

| 1″ | 14M | 30M | 0.5M3/ Hr | 350 | |

| Pop up Sprinklers | 1/2″ | 7M | 20M | 2M3/ Hr | 2,750 |

| 3/4″ | 14M | 30M | 3M3/ Hr | 3,750 |

2. Rain gun sprinklers

These are larger sprinklers to irrigate small to large acreage of commercial crop. They vary in size and make.

2.1. Flange type rain guns

They are giant rain guns that evacuate large amounts of water, and work under high pressure. They are in large plantations

A flange type rain gun in a large field

2.2. Atom rain gun

2.3. PY type rain gun

2.4. Plastic rain gun

Rain gun price in Kenya

| Type | Make | Inlet Diameter | Max Spray Diameter | Min Head (Pressure Rating) | Max Flow Rate | Price in Kes |

| Flange | Metallic | 2″ | 60M | 50M | 60M3/ Hr | 65,000 |

| Flange | Metallic | 1.5″ | 45M | 40M | 40M3/ Hr | 50,000 |

| PY 50 | Metallic | 2.5″ | 40M | 30M | 25M3/ Hr | 19,000 |

| PY 40 | Metallic | 2″ | 35M | 30M | 17M3/ Hr | 17,000 |

| PY 30 | Metallic | 1.5″ | 30M | 30M | 8M3/ Hr | 15,000 |

| Atom/ RM | Metallic | 1.5″ | 30M | 30M | 8M3/ Hr | 17,000 |

| Plastic | Plastic | 1.5″ | 30M | 25M | 7M3/ Hr | 5,000 |

| Atom/ RM | Metallic | 1″ | 20M | 30M | 6.5M3/ Hr | 6,500 |

Greenhouse Sizes In Kenya

Greenhouse sizes in Kenya range from smal units of 120M sq, to large commercial structures spanning dozens of acreage. The most common greenhouse size in Kenya are tabulated below

Greenhouse Sizes In Kenya

A. Small

| Dimensions in meters | Tomato Crop Population | Price in KES |

| 15 x 8 | 600 | KES 195,000 |

| 24 x 8 | 800 | KES 275,000 |

| 30 x 8 | 1,200 | KES 365,000 |

| 40 x 8 | 1,500 | KES 530,000 |

| 48 x 8 | 1,600 | KES 600,000 |

2,880M sq of greenhouses contructed for a medium scale farmer in Heni area, nyandarua county. The target crop is herbs and spices

B. Medium

| Dimensions in meters | Tomato Crop Population | Price in KES |

| 24 x 16 | 1,500 – 1,600 | KES 540,000 |

| 30 x 16 | 2,400 | KES 660,000 |

| 40 x 16 | 3,000 | KES 990,000 |

C. Large From 800M square. Kes 900 per meter square. We customise our price according to size, and your greenhouse budget

What determines greenhouse sizes in Kenya?

- Land area. The size of the greenhouse will be limited to the amount of land available to develop

- Water availability. The larger the greenhouse, the greater the water use

- Use. A seedlings propagation greenhouse unit in a fram will be smaller than the commercial units where these seedlings establish as crops in the same farm

- Budget. Greenhouse construction is a capital undertaking. The size of the greenhouse unit will be determined by the capital available

Greenhouse Sizes in Kenya

Construction materials

I. UV treated greenhouse polythene with anti drip properties

This is the key material that protects the crop from the elements of weather; sun, wind and rain. It creates the ‘greenhouse effect’, and minimises disease and pest incidences on the crop. It is either clear or yellow in color. Clear greenhouse polythene for fruiting crops, or in ornamentals, bi or multi colors. This is because it allows in more light which these need for photosynthesis, the process that makes food for the plants. Yellow is for vegetative crops, and mono color ornamentals. In mono color ornamentals, it intensifies the color

II. Galvanised steel bars

They provide structural support to the greenhouse, and also to the crop as ‘crop support structures’ for tall indeterminate crops such as; tomato, peppers, and cucumbers

III. UV treated high density insect nets

These nets keep away insect pests. They are for self pollinating (do not require external pollinators such as insects and birds) greenhouse crops

IV. Bird nets

These are only used in greenhouse crops that require insect pollination from bees, butterflies, hornets and many other pollinating insects. They allow in the insects, but keep away bird pests. An example of such a crop is strawberry

V. Profiles

They are screwed onto the galvanised steel bars so that the greenhouse cover is tucked in them

VI. Wiggle wires

Once the greenhouse cover is tucked in the profile, wiggle wires keep it in place so that it is not removed by wind or other physical force. Wiggle wires have a plastic covering to prevent damage to the greenhouse paper the are in direct contact with

Wiggle wires hold in place a clear greenhouse polythene sheet tucked in a profile

VII. Screws

The join the profiles to the galvanised steel structure

VIII. Concrete

This is what supports the galvanised steel structures on the ground and keeps them upright

Humidification through misters in a seedlings propagation greenhouse

Successful greenhouse farmers in Kenya grow both none food and food crops in our metallic greenhouses. Common greenhouse food crops are; tomato, peppers, strawberries, and cucumber. Galvanised steel bars, insect netting, screws, and profiles are our greenhouse construction materials. With labor addition, all now constitute your final greenhouse cost Every Grekkon Limited greenhouse has a drip irrigation system for crop production, or a misting/ fogging system for seedlings propagation. Sprinkler irrigation systems are not installed in greenhouses

Greenhouse Sizes In Kenya

FAQs

1.What is greenhouse farming?

2. What is the most profitable crop to grow in a greenhouse?

A 30M x 8M tunnel type greenhouse by Grekkon Limited in Rimuruti area, Laikipia county. Notice the front sanitary pouch, and side roll up

3. How profitable is greenhouse farming in Kenya?

Greenhouse farming consists of self-pollinating crops such as greenhouse indeterminate tomatoes, peppers, and cucumbers, and also insect-pollinated crops like strawberries. These are high-value crops that require intense attention and protection from pestilences such as; hail, drought, pest, disease, storms, and cold. They are moderately profitable. We design none food metallic greenhouses for flowers such as; roses, carnations, and chrysanthemums, and herbs such as geraniums, mint, basil, rosemary, and lemongrass. These crops are highly profitable and are grown by successful greenhouse farmers in Kenya.

4. How do you build a greenhouse?

Greenhouse farming in cool highland zones will have a tunnel-type greenhouse constructed because it conserves heat, while those in the warm lowlands will have a vented type greenhouse that allows better cooling. The difference between the two greenhouse types is that the vented type has a roof top ventilation. This is created by overlapping one side of the roof above the other (see the wooden greenhouse image below) Our sizes range are small, medium and large

The interior of the tunnel type greenhouse

6.How thick does the plastic need to be for a greenhouse?

It will be 200 to 220 microns. Our greenhouse polythene price in Kenya is Kes 96/MSQ7. What is the best covering for a greenhouse?

8. Are greenhouse tomatoes better than outdoor tomatoes?

Greenhouse tomatoes have less pesticide applied to them because the crop is protected. Greenhouse tomato farming prevents high pests and diseases outbreak. These tomatoes have a lower shelf life than open field tomatoes because their rind is softer than open field tomato. Complete exposure to the sun is what gives open field tomato tougher rind, assuming the same level of nutrition for both. To increase the shelf life of greenhouse tomato, calcium and boron feeding is necessary

9. How well can a small-scale farmer run a greenhouse?

Grekkon Limited has developed manuals to assist small-scale farmers to achieve high yields in their greenhouses. We also conduct crop assessment visits during the first 4 months of production, free of charge. The reason we make it 4 months is because by this time, the crop has been harvetsed severally and the farmer knows all the basics of production

A low cost vented type wooden greenhouse in Kenya by Grekkon Limited

A low cost vented type wooden greenhouse in Kenya by Grekkon LimitedGreenhouse Sizes In Kenya

How profitable is greenhouse farming in Kenya?

How to get high yields in your greenhouse farming

1. Soil test

Conduct a soil test to determine the right fertiliser regime. A soil test will be done in a soil testing laboratory after soil samples are collected from the site.

2. Nutrition

Before making your beds, trench to 2 feet and add manure mixed with soil and ash then do your bed over this trench. This will feed your indeterminate crop for many months, providing consistent productivity

3. Water usage

Drip irrigation is the method of watering your greenhouses. Tomato farming, strawberry farming, pepper farming, herbs farming, cucumber farming, and for every crop in the greenhouse.

4. Crops to grow

Indeterminate vegetable crops like; tomato, cucumber, strawberries herbs, and peppers. This is because the yield over a prolonged period of time, which is key in returning the greenhouse investment

5. Pests and diseases

Greenhouses reduce the incidence of pests and diseases because the crop is under a protective greenhouse cover

Ripe greenhouse tomato fruit

Ripe open field tomato fruits

Greenhouse Sizes In Kenya

Summary

For your greenhouse investment in Kenya, we provide a kit for an additional cost that consists of;

- Seedling trays

- Coco peat

- Fertiliser (planting and topdressing)

- Pesticides; insecticides (long and short PHI), and fungicides (preventive and curative)

- Personal protective equipment

- goggles

- gas mask

- overalls

- gloves

- gumboots)

- A 20-liter knapsack sprayer

This secures your greenhouse budget. Our technical team is at hand to guide growers on the best greenhouse cost and sizes based on; crop type, location, and budget.

Spraying agrochemicals on a young open field tomato crop donning the full PPE kit

One acre rain hose kits

Grekkon Limited’s one acre rain hose kits in Kenya installations are done by the technical team across the country. The number of rain hose pipes installed per acre is determined by the following:

A one acre rain hose irrigation system installed by Grekkon Limited in Makutano area, laikipia county

- the available flow rate, and pumping pressure from the water pump or water source. Where the flow rate and pumping pressure is high, the diameter of reach is broad, so less rain hose pipes are needed

- the diameter of the pipes. Larger diameter rain hose pipes provide more water, over a larger area, so less of them are needed

Cost of one care rain hose kits in Kenya

| Diameter size | Flow rate per 100M | Price in KES |

| 32mm or 1″ | 13 cubic litres per hour | KES 85,000 |

| 40mm or 1-1/4” | 16 cubic litres per hour | KES 78,000 |

| 50mm to 1-1/2″ | 22 cubic litres per hour | KES 70,000 |

Rain hose pipes work under high gravity pressure (from 6M or 0.6bar), and with high volume water pumps. The discharge rate of the water pump is from 40 cubic litres per hour. These water pumps are surface solar, electric, petrol or diesel powered

One acre rain hose kits in Kenya

Installation

- Trench where the poly vinyl chloride (PVC) main line will be laid. This is not necessary for the high density polyethylene (HDPE) which are surface pipes. PVC pipes are sub-surface pipes because they have no UV-treatment, and will thus degrade easily under the sun. HDPE pipes have UV treatment and will be surface pipes

- Connect the PVC or (HDPE) main line to the water pump or high tank. This pipe evacuates water from the source to the farm and is the largest in diameter. The larger the pipe diameter, the more the water it delivers. .

- Join the HDPE or PVC sub-main line to the main line. The sub-main line is smaller in diameter, and so carries less water. It is joined to the main line through PVC or HDPE accessories such as; tees, elbows, saddle clamps, adaptors or valve sockets

- Connect the rain pipe to the sub-main line or the main line where a sub-main line does not exist. This is done with a rain hose connector or a saddle clamp

- Spread the rain hose along the length, and close the terminal end with an end cap

- Connect one rain pipe to another with a connector

Rain hose fittings from left to right: end cap, connector, rubber, and ball valve

A drilling tool is the only tool used when installing a rain hose kit. This is to create an opening on the main or sub-main line to insert the rain pipe ball valve

One acre rain hose kits

Components of a rain hose irrigation kit?

1. End-caps. They close the end of the pipe to prevent further water flow 2. Starter off-takes. They connect the rain pipe to the PVC or HDPE main line that supplies water to the rain hose from a water pump or highly elevated water tank 3. Pipe connectors. To connect one rain hose pipe to another 4. Mini valves. To control water flow to the rain hose pipe

The diameter of the pipe are; 25mm, 32mm, 40mm and 50mm. A grower chooses the preferred size based on crop water needs and area of irrigation. For instance, a farmer with 1 acre of the crop will comfortably water with the volume delivered through a 32mm rain hose pipe.

Another grower with 5 acres will better irrigate with a 50mm rain hose pipe. An acre of crop uses 1,000 meters of 25mm, 800 meters of 32mm rain hose pipes, 600M of 40mm pipes, and 400M of 50mm pipes

One acre rain hose kits

Rain hose irrigation system requirements

- The system requires a pressure head of 30M, and above

- When using a water pump to power the rain hose irrigation kit, the discharge rate should be from 45 cubic litres per hour

- The rate of water discharge is determined by the diameter size, and number of pores on the rain pipe. For instance, a rain pipe with 5 holes per cluster discharges less water than the one with 7 holes in a cluster

- It irrigates in opposite directions at a radius of 3M for the 32mm pipe, 5M for the 40mm pipe, and 7M for the 50mm pipe

- The vertical height of this water jet is 1M

One acre rain hose kits

FAQs

a. What is the difference between a rain hose irrigation system and a sprinkler system?

- The technology. The rain pipe irrigation system is designed using nano technology

- The mode of spray. A sprinkler sprays its water in one direction, a rain hose pipe sprays in 3 directions (vertically, horizontally, and diagonally)

- Placement. A sprinkler is placed upright on the surface or sub-surface (for pop up sprinklers). A rain hose is laid on the ground

b. What is the pressure in a rain pipe?

The minimum operating pressure is 30M head / 3 bars

c. What is the spacing for rain hose irrigation?

The distance from one rain pipe to another is from 1.5M depending on the operating pressure, and pipe diameter

Grekkon limited is the largest supplier and installer of rain hose irrigation systems in Kenya, and in the east and central Africa region

Micro Sprinklers In Kenya

Micro sprinklers in Kenya by Grekkon Limited are low-pressure, low to medium volume irrigation equipment that are ideal for micro-irrigation. They deliver water directly to the crop root zone, in a uniform manner. They provide full scale surface irrigation, and localised watering of crops. Micro sprinklers are used for; fruit tree, lawn, hedge, and small garden irrigation

Micro sprinkler price in Kenya

The unit cost of all types of sprinkler jet micro sprinklers at Grekkon Limited is from Kes 100 at any of our branches nationwide. Micro sprinkler price per acre is a factor of the number of units used, which depends on the crop spacing. For instance tree tomato spaced at 2M x 2M will require a higher number of micro sprinklers than avocado spaced at 6M x 5M

Each unit is composed of 3 parts; the sprinkler, the 8mm diameter connecting tube, and a 1-1/2′ long plastic support stand

Micro sprinklers save water through high application efficiency, and uniformity of spray. They are a substitute for button drippers where drip irrigation is impractical, but create a larger wetted area than drip irrigation. Micro sprinkler irrigation provides low precipitation which allows for longer watering time with low run-off. They are available in a wide range of plastic configurations. Micro sprinkler sets are used with fertigation systems which save on fertiliser application labour cost. They are also light in weight and small in size, which makes them highly portable, and easy to install

Micro sprinklers watering an apple crop

What is micro sprinkler irrigation?

It is micro irrigation through the adoption of sprinkler jet micro sprinklers, set at the base of the plant

Micro Sprinklers In Kenya

Coverage:

Micro sprinklers coverage is a factor of; flow rate, wetting diameter or radius, and the wetting degree.

1. Operating pressure; from 15M head / 1.5 bar – 20M head/ 2 bar. Pressure lower than this will cause the micro sprinkler to release large droplets, or cease rotation. These droplets will be unhelpful, or even destructive to the work undertaken

2. Flow rate 40 litres per hour

3. Irrigation degree; available as 90, 180, and 360 degrees

4. Irrigation dimeter; 1.5M to 3.5M. This is an important factor to note during installation because it guides on the spacing of one sprinkler jet micro sprinkler to another

Micro sprinklers work when positioned upright, or upside down. Upright when they’re standing on the ground for normal irrigation. Upside down when set in a greenhouse, or open field crop to provide humidity to a mature crop or seedlings. This upside down placement is also for keeping plant foliage moist, or for overhead irrigation.

They deliver irrigation water through micro tubing to a series of nozzles attached to risers. They have small to medium sized droplets with good uniformity of coverage, and lower precipitation rate.

How to space micro sprinklers

Micro sprinklers placement is in such a manner that the sprays overlap. If for instance the irrigation diameter is 1.5M, the distance between micro sprinklers will be 2.25M. This ensures that there are no dry spots in between. An overlap ensures full coverage particularly for lawns, hedges or very closely spaced crops

How to use micro sprinklers with fruit trees

Our micro sprinklers for orchards are installed this way: Set one micro sprinkler per tree, 30cm or 1 foot from the base of the tree trunk being irrigated. Unlike online or button drippers which work well with gravity, a water pump will be necessary when irrigating with many micro sprinklers. This is because they need an operating pressure of 15M – 20M head, which is best achieved by a water pump

How much water do micro sprinklers use?

They use a maximum of 40 litres per hour

Micro Sprinklers In Kenya

FAQs

1. How effective is micro sprinkler irrigation?

It reduces water usage by 25% to 40% compared to impact or rain gun sprinkler irrigation, and by 45% to 60% when compared to surface irrigation. They provide uniform water application which ensures uniform growth and crop maturity

2. How far apart should sprinkler jet micro sprinkler be?

It should be less than the radius of their spray. See details above under the heading how to space micro sprinklers

3. When do you use a micro sprinkler?

Like drip irrigation, they are great for water conservation. However, unlike drips they create a humid micro climate around the crop, which is important in the control of certain pests such as spider mites, arphids, and thrips,

4. What are the disadvantages of micro sprinkler irrigation?

4.1. The tubes get clogged more easily than those of an impact sprinkler or rain gun sprinkler. This is because they are much smaller than those of other sprinkler types

4.2. They are more expensive to install than drip lines, or button drippers

4.3. They require higher operating pressure than drip lines, or button drippers, hence the need to invest in a water pump

4.4. They require a higher level of expertise during installation than button drippers, or drip tapes

4.5. The rate of water loss due to evaporation is higher than with a button dripper, or drip irrigation system

4.6. Many units are required per unit of land compared to other larger sprinklers

5. How do micro sprinklers work?

They have micro tubings which deliver water to small openings that release it at a slow rate, as fine particles. They apply water directly to the soil surface allowing it to percolate under low pressure

6. How far do micro sprinklers spray?

1.5M to 3.5M diameter

7. What are the components of a micro-irrigation system?

7.1. A pumping station to provide the right pumping pressure

7.2. A filtration system to capture any debris or dirt that will clog the system

7.3. Mainlines. These are the pipes originating from the pumping station, and feeding the sub-main lines. They are the largest pipes

7.4. Sub-main lines. These are the pipes origination from the main lines, and feeding the laterals. They are smaller in diameter than the main lines

7.5. Laterals. These the pipes connecting to the sub-main lines, to which the micro sprinklers are attached. They are the smallest pipes in diameter

These pipes will be either be of the high density polypropylene (HDPE), or poly vinyl chloride PVC type

7.6. Hydrants. These are the irrigation control units in the field from which water is channelled to various blocks

7.7. Venturi system. This is a chemigation and/or a fertigation unit connected to the main line. It is the point from which soluble fertiliser and drenching pesticides are fed into the irrigation system

A venturi fertigation – chemigation unit being set up in an upcoming vegetable farm by Grekkon Limited

7.8. The sprinklers. They water the crops directly

8. How long to run micro sprinklers in Kenya?

35 to 45 minutes is sufficient time at optimal flow rate and working pressure

9. What is the difference between drip irrigation and micro sprinklers?

Drip irrigation is for closely spaced crops that require targeted irrigation. Micro-sprinkler irrigation is for sparsely spaced, larger crops or crops that grow best under overhead irrigation

10. What is the difference between mini and micro sprinklers in Kenya?

Mini sprinklers are larger, with a greater flow rate and operating pressure to cover a bigger area. They are better for smaller plants or landscape irrigation

Low Cost Solar Dryers

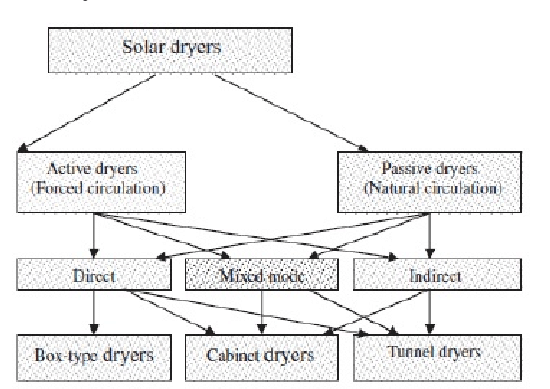

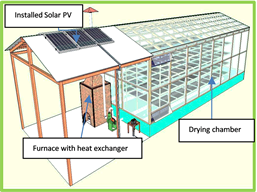

Grekkon Limited is the largest supplier of low cost solar dryers for agricultural products in Kenya . These low cost solar dryers work on solar strength, and are also augmented with a biomass heat unit if so desired by the client. Our agricultural solar dryers design is according to the product, location, and drying volume per session.

These passive or active solar dryers for fruits and vegetables are fixed or portable as the user needs it. The fixed ones are large and impractical to move about, while the portable one are small domestic drying units

What are low cost solar dryer prices in Kenya by Grekkon Limited?

We price according to size & type. The table below illustrates some sample design pricing for passive solar dryers

| Solar Dryer Size | Drying Capacity | Price of Solar Dryer |

| 1.5m x 1.5m x 1.5m | 40-50kgs | KES 70,000 |

| 2m x 2m x 2m | 50-90kgs | KES 75,000 |

| 2m x 3m x 2m | 80-100kgs | KES 95,000 |

| 2m x 4m x 2m | 90-110kgs | KES 100,000 |

| 2m x 5m x 2m | 100-130kgs | KES 120,000 |

| L X W x H |

Solar dried mango slices

Low Cost Solar Dryers in Kenya

Grekkon limited designs and constructs both passive/ natural circulation, and active/ forced circulation low cost solar dryers for agricultural products. The passive solar dryers have no additional mechanical input, while the active dryers do. Active solar dryers are also know as hybrid solar dryers. Their additional mechanical inputs are; a biomass heating unit, or solar powered exhaust plus extraction fans, and synchronizers. A hybrid solar dryer will have one (solar system or biomass heater) of these enhancements, or both. These enhance drying time by 30% to 100% compared to passive drying. Attached biomass heating units allow for night time drying, or on cloudy/ rainy days.

Solar Dryer Materials

- Light UV treated translucent polythene paper to allow heat and light. The paper also has anti-drip treatment to prevent dew formation which causes moulds to form on food

- Heavy UV treated geomembrane to conserve heat

- Steel bars galvanized with food-grade aluminum or zinc for food safety

- UV treated heavy gauge netting to prevent insect pests from entering

A simple portable solar dryer under construction by the Grekkon technical team at Rusinga Island, Homa Bay county. The local community will dry bananas for processing into flour

Below are 2 videos: The first one is of a farmer in Homa-bay county, western Kenya using a community passive/ natural circulation solar dryer to add value to banana produce. The second one is of a mango processor in Taita Taveta county at the county’s coast with an active/ forced circulation dryer. Both solar dryers are by Grekkon Limited.

Video 1. Video 2.

Our low cost solar dryers have shelves at different levels depending on the volume or weight of food crops to dry per session.

Low Cost Solar Dryer Design

What is the working principle of a solar dryer?

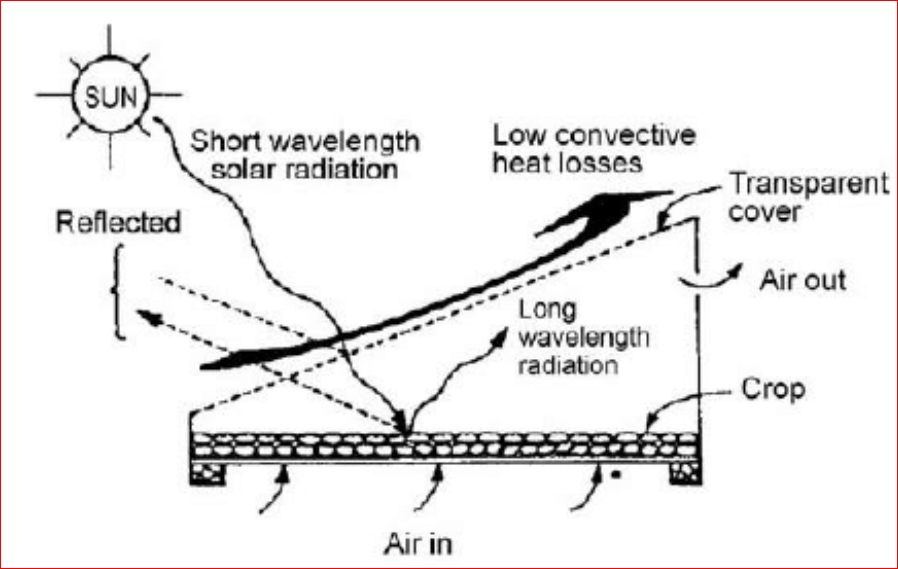

1. Passive/ Natural Circulation Food Solar Dryer

Grekkon Limited solar dryers work in the following steps;

i. Capture & collect the sun’s heat

ii. Create a ‘greenhouse effect’ which causes moisture loss from the produce

iii. Air coming into the dryer exits with this moisture from the vent

2 Active/ Forced Circulation Food Solar Dryer

In addition to what takes place in the passive solar drying unit, the fans force in hot air from outside, and force out hotter air combined with moisture from inside the dryer. At night or on cloudy/ rainy days, the biomass unit supplies the drying heat.

Pros and cons of a low cost solar dryer in Kenya

- Speed of drying. Food dries four to five times faster.

- Quality. As the sun’s UV rays do not get into direct contact with the drying food, the food’s; color, taste, scent, and nutritional value is unaffected

- Cleanliness. The food is free from dust, sand, or other external contaminants

- No pests. Insect, bird, or mammalian pests have no access to food in the dryer, so no attack occurs

- It is more expensive to build and maintain than open-air drying

Solar dried chilli peppers

Low Cost Solar Dryers

FAQs

I. What are solar dryer prices in Kenya by Grekkon Limited?

We price according to size & type. The table below illustrates some sample design pricing for passive solar dryers

II. How does a vegetable dryer work?

- Heat

They allow in diffused heat from the top and the sides, which heats up the air coming in from the air inlet. This hot air will exit with moisture in the air outlet.

- Anti-drip management

Our UV treated polythene cover has anti-drip properties so water droplets do not form on it. It prevents dripping on the drying food which is a precursor for fungal development.

III. What do a low cost solar dryers do?

Grekkon Limited’s solar dryers reduce the moisture content to less than 12% in these products;

- Plantation crops; coffee, rice, cassava

- Vegetables; tomato, onion, garlic, brassicas, hot peppers

- Cereals; sorghum, and millet

- Herbs; moringa, mint, rosemary

- Oil crops; groundnuts, sunflower, macadamia, cashew nuts

- Others; mushrooms, fish, beef, mutton

IV. How do you dry vegetables with solar?

- Wash the vegetables to remove all dirt

- Ensure there are no insect pests present

- Remove any diseased parts or produce

- Cut or grind them into smaller pieces to increase the drying surface area

Place them in the solar dryer holding trays

Dry cassava chips

V. What is the most popular use of low cost solar dryers?

To dry fruits, mushrooms, vegetables, herbs, spices, coffee, cassava, banana and fish. Banana and cassava are further processed into food flour. A solar dryer ensures that the food is free of any external contamination

VI. What are the main applications of a solar dryer?

Besides vegetables and fruits, commercial solar dryers in Kenya are for fish, root crops and mushroom drying. Commonly dried foods in Kenya through our solar dryers are:

i. Banana, cassava, pumpkin, millet, and sorghum to make food flour. Dried cassava is also processed for industrial starch manufacture

ii. Moringa as a medicinal herb

iii. Tomato, capsicum, traditional vegetables, kales, and spinach as vegetable nutrients

iv. Mango, papaya, as dried fruits for snacking

v. Omena which is the silver cyprinid fish for both human consumption, and as additive to animal feed

vi. Coffee so that it’s suitable for milling. Coffee solar dryers are the largest, each holding over 5 tons of berries per drying session

Plastic Rain Gun Sprinkler

Our plastic rain gun sprinkler in Kenya is the Shrub body style whose application is both domestic and industrial. Grekkon Limited’s low pressure plastic rain guns are 1-1/2″ in size. It is a double nozzle with additional detachable nozzles as; 6mm, 8mm, 12mm, and 16mm

This irrigation sprinkler is lighter than it’s metallic counterpart, but with a shorter longevity. It makes it highly portable to reach any point in your farm. It is black in color because it is made from high density polyethylene material (HDPE). This material is UV- treated to reduce it’s degradation by the sun, thus extending the sprinkler’s working life. UV treatment is an important quality in tropical climates where radiation is high. Every tropical grower ought to consider this because it impacts the working life of the rain gun sprinkler

This irrigation rain gun for sale works with water pumps to provide requisite pressure. The necessary water pump specs are:

- It will be electric, diesel or petrol powered

- It must provide a minimum pressure of 3 bars,and a discharge of 8 cubic liters per hour

- The outlet pipe is 1-1/2″ and above. A delivery, HDPE or PVC irrigation pipe evacuates the water from the pump to the sprinkler.

The rotation is up to 360 degrees. A farmer will adjust the rotation area manually as necessary using the pins below the nozzles. All metallic parts are rust proof and the rubbers are easy to replace once they wear out. Our plastic rain gun sprinkler features a friction collar and a trip lock, and are also provided with a jet breaker for uniform water application

Types of rain gun sprinklers

1. Plastic

2. Metallic; PY type, Atom and the flange type rain gun sprinklers. Learn more here; https://grekkon.com/rain-gun-sprinklers-2/

Plastic Rain gun sprinkler specifications and price

| Type | Body Type | Inlet Diameter | Max Spray Diameter | Min Head (Pressure Rating) | Max Flow Rate | Price in Kes |

| Plastic | Shrub | 1.5″ | 30M | 25M | 7M3/ Hr | 5,000 |

Plastic Rain gun

Product benefits

- This is ideal for newly cleared areas

- It reduces irrigation time

- Low labour cost

- High efficiency

- Improves humidity or creates a micro-climate

- It is easy to maintain and use

- Irrigates a much wider area than conventional smaller impact sprinklers

Disadvantages of rain gun irrigation

- It consumes a large amount of water

- The need for a high amount of power makes it costly to operate

FAQs

1. How much horsepower (Hp) is required for a rain gun?

This depends on the rain gun sprinkler size. The larger it is, the greater the discharge, and so the greater the power needed. Another factor is the number of rain guns set to run at a go. Generally, it is from 8.5Hp

2. Is rain gun good for irrigation?

Yes it is. However, do not irrigate on crops that are highly susceptible to fungal infections with overhead irrigation. Examples are; tomato, potato, capsicums, and others