Drip Irrigation System Layout

Grekkon Limited’s drip irrigation system layout is done for all farm sizes, and all crops. There 3 ways in which the company gathers data to develop a drip irrigation system layout

- Farmers provide detailed sketches as directed by the company from which a drip irrigation system layout is developed. This sketch will include; the farm dimensions in meters, the water source type, distance to the water source from the farm, details of any existing irrigation infrastructure, any existing roads or pathsways, any none farmable sections (rocky areas, wet lands, built up locations etc), planting beds layout, the direction(s) of slope, and the total vertical elevation

- Provide the farm’s map coordinates from which the company assesses the farm layout using satellite technology

- Conduct a physcal site assessment visit. This is only carried when 2 above cannot be done

The company only charges for the 3rd service to cover the logistical costs

A sample drip irrigation system layout for a 40 acre farm by Grekkon Limited

The company’s irrigation engineers will conduct a physical visit on a prospective farm to determine the following

i. The water source. The company measures the water volume, and analysis the quality. The volume determines the irrigation system to use, the size of the water pump, and the acreage covered. For intance, a farmer with a borehole yielding 15 cubic litres per hour is best positioned to irrigate using drip irrigation. His irrigated acreage will not exceed 30 acres for optimal water utilisation. On the other hand, a farmer by a large permanent river or lake water source will irrigate hundreds of acres using any irrigation method preferred. The water quality determines the type of filtration system to install.

A screen filter is for water under low pressure with a negligible amout of suspended dirt or other particles. A disc filter is preferred for water under high pressure, with a negligible to a modest amount of suspended dirt orcother particles. A sand filter is for dirty water under high pressure

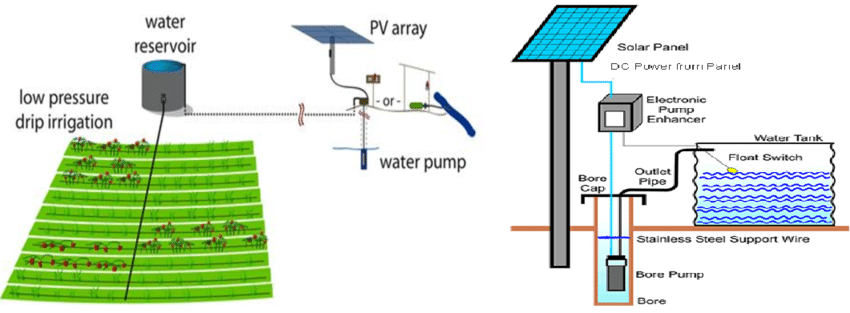

A simple drip irrigation kit by gravitational flow system layout

ii. The dimensions of the farm in meters. to provide the total acreage. The acreage will determine the pipe diameter sizes, the water pump’s flow rate, and the sub-division of the irrigation blocks

iii. Slope. The elevation of the farm gives the vertical head or lift needed. This is important in determining the pressure rating of the water pump to install, the pipe diameters, the planting beds layout (these should be done against the slope), and the size of the irrigation blocks

iv. Any existing irrigation infrastructure; to determine what can be used or incorporated into the new system

v. Provide advise on security measures for key company installations such as; large water pumps, solar modules, solar inverters, control panels, cables, and other high value accessories

Key Requirements To Install A Drip Irrigation System

1. A water source

2. A water pump and piping mechanism to move this water from the source to the tank or directly to the drip irrigation system.

3. Water storage tank if you’re using gravity to irrigate

4. A tank connector

5. Pipes for the mainline and sub-main line.

6. Mainline and sub mainline fittings

7. Drip irrigation water filter

8. Drip irrigation pipes

9. Accessories

10. Ball valves

Steps To Follow In Designing A Drip Irrigation Layout

- Determine where the water pump or water tank will be placed. Water tanks are used for small acreage gravity flow irrigation, and should be placed at highest elevation to allow ease of water flow by gravity

- The main line originates from the water tank or water pump. The size of the main line determines the volume of irrigation water delivered to the farm in every irrigation session. The larger the farm, the greater the diameter of the mainline

- The water filter is connected along the main line

- A venturi fertigation system where needed is along the main line. The venturi fertigation system is a chemifertigation centre that allows drenching of chemicals and fertiliser through the drip irrigation system

- The air release valves are along the main line. Air release valves are installed where the water pressure is high. This is in steep elevations, or if the water is chanelled via a high pressure water pump. They prevent air locks in the irrigation system. Air locks dramatically reduce, or cease water flow in the system

- A sub main line will be connected to the main line along its way using hydrants. Hydrants are points from which irrigation in a block is controlled from. They can be automated using solenoid valves, or manually operated through ordinary valves. The decision to have sub main lines is a factor of the farm size. In small drip irrigation set ups, the drip pips are directly connected to the main line. In larger acreage, the drip line originate from the sub mainline

- The main line is always larger in diameter than the sub main line. The diameter of the sub main line is determined by the size of the main line. The larger the latter, the larger the sub main line is

- The hydrants are positioned at the beginning or end of every irrigation block

- Planting beds are done against the slope. This is to slow down erosion, and allow better water percolation in the soil during the rainy season. The width of the planting bed is determined by the crop type

- Drip lines lie along the length of the planting beds. The number of drip lines per bed depends on the crop type. E.g 2 drip lines are installed for tomato, 3 drip lines for onion or garlic, and 4 drip lines for some herbs and spices

A 3 row drip layout per bed installed in Birikani area of Kajiado county

Adjustable Button Drippers For Irrigation

1. What is a button drip emitter?

Adjustable button drippers for irrigation are irrigation accessories attached onto a high density polyethylene (HDPE) pipe.

They deliver a consistent and uniform amount of water the crop by regulating the flow. Button drippers in Kenya, button drip are common in fruit trees, forestry and hedges irrigation

A macadamia crop under button drip irrigation installed by Grekkon Limited in Iten area, Elgeyo Marakwet county. January 2021

Same macadamia crop in January, 2023

2. How do you install button drippers?

A perforation is made on the HDPE pipe with a drip punch, then the button dripper’s pointed end is pushed into this hole. This punching is done at the point where the tree crop is. But it will be away from the trunk to ensure that water flows to the roots below. The button dripper will be 3-6 inches away from the trunk. This will also prevent fungal infections and other types of diseases.

For younger tree crops, a single button dripper or emitter is sufficient. However, with older larger trees, 2 or more button drippers are provided according to the plant’s water need. In this case, have them equally on the opposite sides of the tree crop to promote even root growth. Two or multiple button drippers ensure that if one is blocked, the other one or the rest continue to water

3. How do you use an adjustable button dripper?

Once in place on the irrigation line, you will adjust your button dripper from 0 discharge to 70 liters per hour flow of water. This is done by turning the dripper to achieve different flow rates as per the crop water needs

4. How long should button drippers run?

Your adjustable button drippers for irrigation will run for 30 minutes to an hour. This is guided by the moisture requirement of the soil, as per the prevailing weather conditions

5. How many button drippers can I run on one line?

This is determined by the diameter size of the irrigation pipe. The larger it is, the more water it ferries over a longer distance. Therefore, the greater the number of button drippers. The other factor is the flow rate of the adjustable button drippers themselves. If adjusted to maximum flow rate (70L per hour), then the line will have less. If the adjustment is to half of that flow rate, then a similar line will carry twice as much

6. How do I increase the pressure in my button drip irrigation system?

They are several ways to raise the irrigation water pressure in your button drip irrigation system

i. Divide the farm into blocks, each of which is irrigated separately. This way, irrigation water is channeled to particular block under high pressure

ii. If it is by gravity flow, then by raising the storage elevation. This will work where raised water tanks are the source of irrigation water

iii. By introducing an external source of pressure, such a s water pump to boost the flow of irrigation water in the system

Adjustable button drippers for irrigation price in Kenya

The cost of a button dripper is Kes 12 a unit

The cost of a button dripper irrigation system per acre depends on the tree crop spacing. In the tabulation below, we provide 3 examples

| Avocado | Passion / Paw Paw | Apple / Tree Tomato | ||

| Spacing | 5M x 5M | 3M x 3M | 2.5M x 2.5M | |

| Cost per Acre | Kes 85,000 | Kes 100,000 | Kes 115,00 | |

Solar Dryers For Fruits And Vegetables

Grekkon Limited’s hybrid solar dryers for fruits and vegetables in Kenya are designed to dry faster than the conventional or natural solar dryers. They are enhanced with cyclone roof top vents, and fans on the sides. Hybrid solar dehydrators are efficient for large- scale commercial food drying. This is especially with longer to dry fleshy food like; cassava, banana, tomato, fruits, and rice. Drying time is a factor of the food crop type, and the prevailing ambient temperature during the drying period. The quality of the dry produce is consistent. The dryer works through the greenhouse effect.

Solar Dryers For Fruits And Vegetable In Kenya

Solar Dryer Materials

- UV treated paper on the sides and roof. UV block treatment on the polythene paper extends it’s usable lifetime to 4 years. This treatment prevents UV degradation of the food crop. The polythene paper has anti-drip properties to keep dew from forming on the inside of the paper. Dew drops on the drying food will cause molding.

2. Galvanised steel support structure. Galvanised with food grade aluminum, or zinc

3. Concrete floor for the permanent/ immovable models

4. Heat absorbing and releasing dam liner to line the floor

5. Roof top cyclones. Ensures the air is evenly distributed within so that there are no air pockets. This results in evenness of drying for the produce. We install cyclone roof top vents from a particular solar dryer size

6. Fanning system. This comprises of;

- solar panels; to provide electric DC power

- a control box; to regulate electric current

- an inverter; to convert DC energy form the solar panels to AC to power the fans

- fans; an extraction fan to allow push in air, and an exhaust fan to move out accumulated moisture

7. Nets. High density UV treated nets on the air entry and exit points

8. Drying trays designed with material specific to food drying

Every material used is specific to solar dryers for fruits and vegetables to provide; efficiency, safety, and food quality

Solar drying units by Grekkon Limited in Taita Taveta county enhanced with a solar panel and battery to power cyclones, extraction and exhaust fans. They increase air movement in the solar dryer, thereby hastening the drying process, and also making it even

How To Use Solar Dryers For Fruits And Vegetables

- Chop or slice the produce into smaller pieces. This increases the surface area for drying

- Place these pieces on the drying trays

- Keep the door closed always to avoid food contamination

- Every drying 3 hours, monitor the moisture content using a moisture meter

Solar Dryers For Fruits And Vegetables

FAQs

1. What are the 2 types of solar dryers?

1.1. Passive solar dryers. They only utilise the sun’s warmth

1.2. Active solar dryers. These ar hybrid solar dryers that utilise both passive drying and biomass generated heat

2. How do you make a solar dryer?

Grekkon limited’s low cost solar dryers in Kenya are made from the following materials

2.1. A zinc or aluminum galvanised steel structure. It is rust free and easy to clean with plain water

2.2. UV treated greenhouse polythene with anti-drip properties. The UV treatment prevents food degradation by the sun’s UV rays. It ensures that the color, taste, scent, and nutritional value remains after the moisture is removed. The anti-drip treatment prevents moisture droplets from condensing on the paper and forming drop that will fall on the food. Such drops cause molding

2.3. A heat absorbent floor. his one absorbs heat during the day, and releases it at night reducing tea variance between day and night temperatures. Dew formation and mold development is aggravated by a huge difference between day and night temperatures

2.4. A UV treated heavy gauge insect net to protect the produce from insect pests. This insect net covers the air vents

For a hybrid solar dryer we add all or part of the following

2.5. A biomass combustion chamber with a pipe that carries the heat to into the solar dryer. This one is used at night when there is no sunshine, or on cloudy, cold or rainy days. It ensures continuous drying irrespective of the prevailing weather

2.6. A solar panel with a battery to power cyclones, and extraction and exhaust fan. This system speeds up the drying process by increasing air ,movement withing the solar drying chamber. And also help in evenness of drying in the chamber

3. What is the size of a solar dryer?

Your solar dryer size will be determined by the weight and volume of product dried per session. The larger it is, the larger will be your solar dryer

4. How do I choose a solar dryer size?

Grekkon Limited guides on the solar dryer size a client will need based on the produce type and drying quantity per session

5. What is the mot popular use of a solar dryer?

To cleanly extract moisture (dehydrate) from farm produce, yet retain all other qualities

6. What type of solar dryer is best?

A hybrid solar dryer is the best because it allows for continuous drying; both day and night, and on cloudy or cold days

Water Harvesting With Dam Liners

Water harvesting with dam liners in Kenya is a an important aspect of effective and consistent all year round irrigation. Grekkon Limited is the largest provider of the 3 main types of dam liners in Kenya. This is for water harvesting and aquaculture to smallholder and medium commercial farmers. We encourage every commercial crop farmer to excavate a water pan for off-season production. We then line this water pan with geomembrane material to hold water. Dam liners prevent water loss in the reservoir through seepage into the soil below. Produce cultivated during the off-season fetches better prices, and ensures a consistent farm income. Our dam liners have anti-UV treatment to protect them from long-term solar degradation, which extends their lifespan

A roll of 0.75mm dam liner

Water Harvesting With Dam Liners

Steps:

- Work out the area under irrigation, or to irrigate

- Determine the irrigation method. Each method consumes different amounts of water. We recommend drip irrigation as the most water efficient method

- Understand how long the dry off-season period is

- The 3 workings above will give an indication of the water quantity needed

- Work out the size of the water pan to excavate to hold this amount of water

- Calculate the dam liner size to install in this water pan

An illustration

An acre of strawberry measures 4,048 meters square. The method of irrigation is drip, and strawberry require 100 cubic litres weekly per acre (averagely). The dry period lasts for 32 weeks, so the amount of water needed is 3.2million litres or 3,200 cubic liters to last this long. This assumes zero rainfall in these 8 months, and that there is a shade net covering to prevent evaporation losses

The reservoir dimensions are 36M length x 36M width x 2.5M depth. The total liner needed for this is 1,849 meters square

A newly excavated reservoir with a dam liner covering

Dam Liner Types In Kenya

1. By material

1.1. High density polyethylene (HDPE) geomembrane. These are the most common types because they have additional use in making urban multi-storey gardens

1.2. PVC dam liners. The are soft but heavy. This makes them easier to weld and install

1.3. Low density polyethylene (LDPE). They are soft and light, hence the least popular because they have a short lifespan

HDPE geomembrane pond lining

2. By size

2.1. 0.5mm / 500 microns. For smooth surfaces or soil with light murram particles. It has a lifespan of 15 years

2.2. 0.75mm / microns. For lightly stony or rocky surfaces. It has a life span of 25 years

2.3. 1mm / 1,000 microns. Applied on moderately stony or rocky surfaces. Period of use is 35 years

2.4. 1.5mm /1,500 microns. For application in difficult terrain where the others will not hold

An irrigation water pan with dam liner material

Hybrid Solar Dryers For Sale In Kenya

Hybrid solar dryers for sale in Kenya by Grekkon Limited are active dryers designed to dry quicker, all year round. They are augmented units of the conventional passive solar dryers. The company has three types of hybrid solar dryers for sale in Kenya

- Solar powered. These units have a solar powering system that runs the extraction and exhaust fans. The fans provide better movement of air within the dryer, and removal of the moisture from the drying produce. This hastens the drying process

- Biomass powered. They have a biomass burning unit connected on the exterior. Biomass in the form of brickettes or charcoal heats water which produces steam that travels in tubes within the dryer. This heats up the air in the dryer, accelerating the dring process. Biomass powered dryers can be used at night or on cloudy, rainy or cold days when there is insufficient sunshine to dry

These hybrid solar dryers cost in Kenya ranges from Kes 135,000 to Kes 1,500,000. These hybrid solar dryers for sale in Kenya are for a carrying capacity of 100kgs through 1,000kgs

Hybrid Solar Dryers For Sale In Kenya

Solar Dryer Materials

- Light UV treated translucent polythene paper to allow heat and light. The paper also has anti-drip treatment to prevent dew formation which causes moulds to form on food

- Heavy UV treated geomembrane to conserve heat

- Steel bars galvanized with food-grade aluminum or zinc for food safety

- UV treated heavy gauge netting to prevent insect pests from entering

A hybrid solar dryerwith both an external biomass heating units, and a solar power system

Hybrid Solar Dryers For Sale In Kenya

I. What is hybrid solar dryer?

It is a conventional solar dryer that receives additional drying power from an external source. This could be biomass, solar or electricity

II. What are the three types of solar dryers?

- Natural / conventional solar dryers. These dry using only the power of the sun

- Forced / active dryers. They are augmented versions of the conventional solar dryers

- Portable or fixed solar dryers

III. How does a vegetable dryer work?

- Heat

They allow in diffused heat from the top and the sides, which heats up the air coming in from the air inlet. This hot air will exit with moisture in the air outlet.

- Anti-drip management

Our UV treated polythene cover has anti-drip properties so water droplets do not form on it. It prevents dripping on the drying food which is a precursor for fungal development

IV. What does a solar dryer do?

Grekkon Limited’s solar dryers reduce the moisture content to less than 12% in these products;

- Plantation crops; coffee, rice, cassava

- Vegetables; tomato, onion, garlic, brassicas, hot peppers

- Cereals; sorghum, and millet

- Herbs; moringa, mint, rosemary

- Oil crops; groundnuts, sunflower, macadamia, cashew nuts

- Others; mushrooms, fish, beef, mutton

V. How do you dry vegetables with solar?

- Wash the vegetables to remove all dirt

- Ensure there are no insect pests present

- Remove any diseased parts or produce

- Cut or grind them into smaller pieces to increase the drying surface area

Place them in the solar dryer holding trays

Dry cassava chips

VI. What is the most popular use of solar dryers?

To dry fruits, mushrooms, vegetables, herbs, spices, coffee, cassava, banana and fish. Banana and cassava are further processed into food flour. A solar dryer ensures that the food is free of any external contamination

VII. What are the main applications of a solar dryer?

Besides vegetables and fruits, commercial solar dryers in Kenya are for fish, root crops and mushroom drying. Commonly dried foods in Kenya through our solar dryers are:

i. Banana, cassava, pumpkin, millet, and sorghum to make food flour. Dried cassava is also processed for industrial starch manufacture

ii. Moringa as a medicinal herb

iii. Tomato, capsicum, traditional vegetables, kales, and spinach as vegetable nutrients

iv. Mango, papaya, as dried fruits for snacking

v. Omena which is the silver cyprinid fish for both human consumption, and as additive to animal feed

vi. Coffee so that it’s suitable for milling. Coffee solar dryers are the largest, each holding over 5 tons of berries per drying session

Where to buy dam liners in Kenya

Where to buy dam liners in Kenya is from Grekkon Limited. The company offers the best UV-treated black high density polyethylene (HDPE) dam liners manufactured for tropical climates. Our pond liners for sale in Kenya line the walls and floors of water harvesting reservoirs. This is to prevent water loss through seepage into the soil. Changing rainfall patterns and unpredictable seasons are increasingly becoming a norm in Africa. This is why the need for agricultural water conservation is growing amongst farmers. Every farmer practicing irrigation has a water source

Where to buy dam liners in Kenya

| Thickness | Weight per meter square in Kgs | Price per meter square in KES |

| 0.5mm | 0.46kg | KES 220 |

| 0.75mm | 0.88kg | KES 320 |

| 1mm | 0.91kg | KES 420 |

Water pans lined with dam liners are a source of irrigation water storage. This water is from a larger source such as a lake, river, or borehole water, and also harvesting rain and run-off water. Besides irrigation of your crop, the pond liners on your water pan allows for commercial or subsistence fish rearing; the former to boost household income, the latter to supplement household protein

Where to buy dam liners in Kenya

Dam liners are available in the companies 6 branches located in; Athi river, Nairobi, Kisumu, Eldoret, Nyeri and Nyahururu. We supply pond liners either as rolls of 110M x 8M, 0r cut and welded into the client’s water pan’s specifications

Dam liner rolls by Grekkon Limited

HDPE pond liners cut from a roll and welded to tailor it to the water pan dimensions

Where to buy dam liners in Kenya

Positioning Your Water Reservoir For Irrigation

This depends on:

i. The source of water going into the water pan. If the source is from a lower altitude water source such as a river or lake, the water pan is at an elevated position so that with a water pump, the water is reticulated through irrigation water pipes to the water pan. If the water source is from rain water falling on the roofs or run-off, the water pun is positioned at a lower gradient

ii. Preferred irrigation method. If by sprinkler irrigation or rain hose kits which require high pressure from a water pump, the water pan will be situated at any point. If by low gravity pressure say for drip or button drip irrigation, then it will be at the highest point of the farm

Water harvesting using dam liners

Where to buy dam-liners in Kenya

How to Harvest Water Using Dam Liners

Factors to consider

1. Land size

The amount of water required for half an acre is less than that needed for 20 acres. The latter will harvest more water to irrigate the greater acreage, and the former will have less water harvested. The bigger the volume of water reserved, the larger the dam liner size

2. Location

The amount of rain fall is different in every climatic zone. Growers in the cool wet highlands have just a few dry months in the year, while farmers in the dry zones have more dry months than wet. In regions where the interval between rains is long, larger reservoirs are built for the same acreage as that in the cool wet location. Again, dry locations have very high water loss through evaporation. In this case, it is advised to set up a shade net over the water reservoir to manage this water loss

3. Ground Elevation

The farm gradient determines the location of the water pan. Some choose to have it at the lowest part so as to capture run-off water. If it is for crop irrigation, this water is either pumped uphill to a tank from where it flows back by gravity to the crop. Or it is pumped directly to the crop from the water reservoir. Others choose to locate the water pan on the highest point of the farm so that the water, through gravity flows out to the crop. In this case, the farmer does not retain run-off rain water from the farm. On a flat terrain, irrigation water is physically pumped out to either a high storage tank for onward gravity flow to the crop. Or directly to the crop

A low reservoir that collects run-off rain water

4. Farming System

The size of the water pan will differ for irrigation, compared with aquaculture or livestock production

5. Crop Type

Some crops are more water demanding such as leafy vegetables, than others such as herbs. Then some crops like onion are densely spaced while others are like avocado are sparsely populated in the farm. This will determine the water requirement

6. Irrigation System

Every irrigation system has it’s own unique water use. Drip irrigation conserves water while overhead irrigation through sprinklers or rain hose kits spends huge water volumes

7. Surface Texture

The surface texture of the water pan determines the dam liner thickness to install. For a smooth surface, a 0.5mm dam liner is ok. Where the surface is stony or rocky, then the 0.75mm or 1mm dam line is better

Before harvesting your water using dam liners, ensure that the water pan’s surface is free of debris as much as is possible. This will be stones, rocks, tree stomps, or sticks. This reduces the danger of your dam liner tearing as a result of perforation caused by the weight of the water squeezing the material against these particles

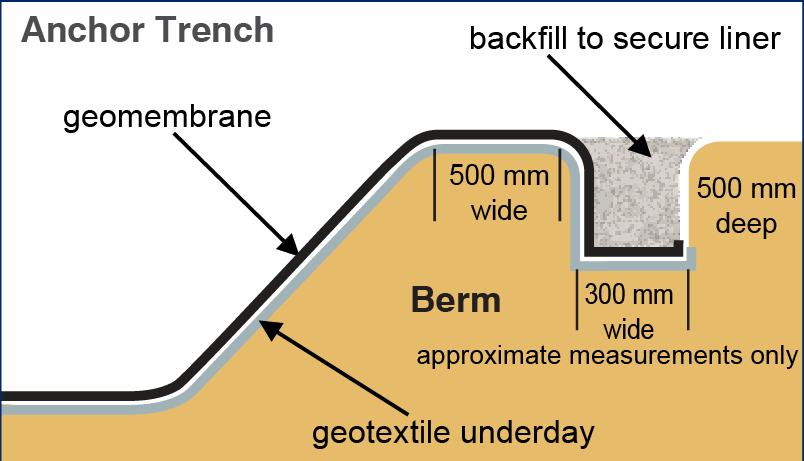

Trench 0.75M to 1M along the perimeter or circumference of the water pan. This trench is 1ft wide and 2 ft deep. Your dam liner edges will be tucked in here and covered with soil, gravel or stones to anchor it in place. Alternatively, use sand bags along the edges to hold your dam liner in place

Where to buy dam liners in Kenya

How Are Dam Liner Sizes Calculated?

Before determining the dam liner size, one must understand the size of the reservoir or tank. This is by measuring the length, width, and depth/ height (for rectangular or square shaped reservoirs/ tanks). For circular or cylindrical tanks/ reservoirs, measure the diameter, and the depth/ height. The reason this is key is because our dam liner material comes in rolls. To make out the shape of the water pan or tank, the dam liner is cut in large bits from the roll and joined together. This is to create the 2 dimension size of the water reservoir or tank. For example; if the width of the dam liner on the roll is 8M, and the water pan requires a width of 15M. Then 2 pieces, one measuring 8M and another 7M in width from the roll are cut and joined to create the 15M width

How Do I Calculate How Much Dam Liner I Need?

The dam liner calculator is adapted to the shape of the irrigation water reservoir as illustated in the 3 different shapes below

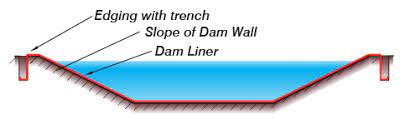

- Sloped sides reservoir

The slope of the dam wall is shown as slanting length (SL) or slanting width (SW) in the dam liner calculator tabulation shown later in this page

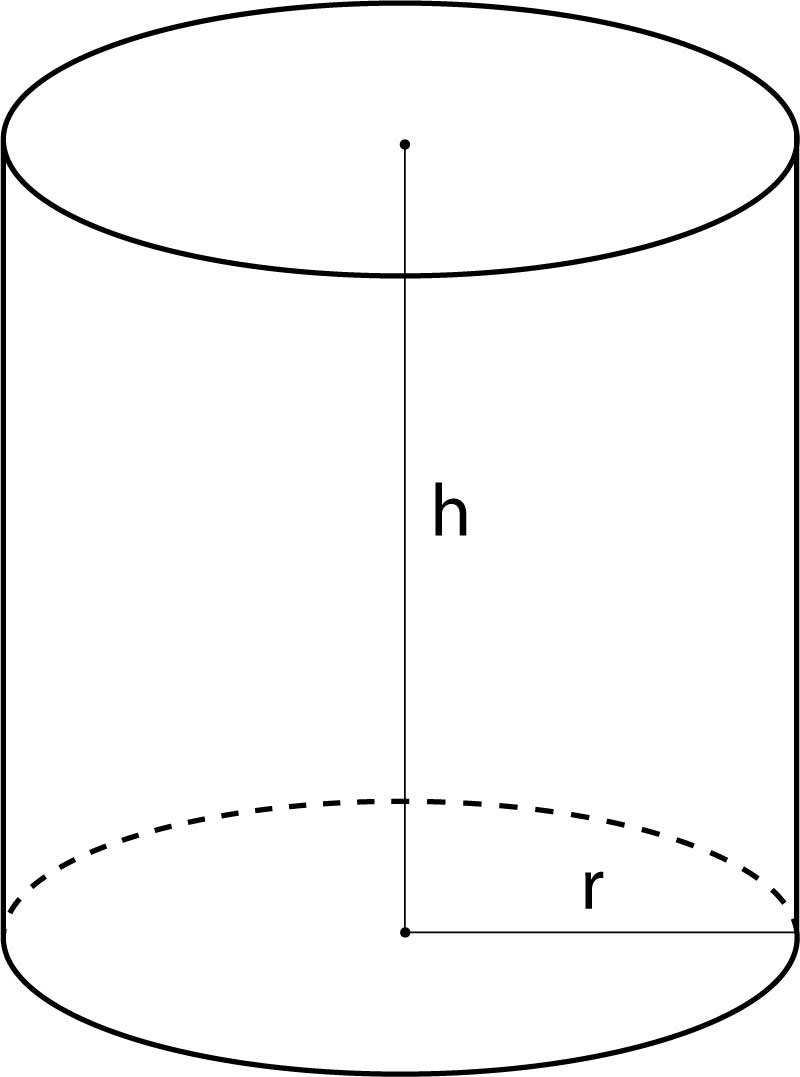

2. Cylindrical circular tanks

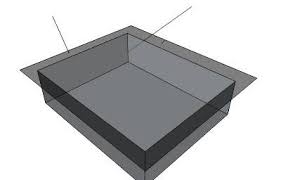

3. Straight side reservoirs

Where to buy dam liners in Kenya

Pond Liner Calculator Table

| Circular Liner | Sloped Sides Liner | Straight Side Liner |

| (Circumference*H+0.6M) + (3.14*3.14*r+0.6M) | (SL*2+D+2M)*(SW*2+D+2M) | (L+2D+2M) * (W+2D+2M) |

If your totals include a decimal say 120.3sq, round it up to the nearest whole number, in this case 121M sq. The +0.6M in the ‘circular liner’ and is the overlap. So is the 2M in the straight side liner’

“D” is the maximum depth which is the center-most point of the reservoir

Where to buy dam liners in Kenya

How much overhang should a pond liner have?

An overhang is the extra liner material that holds the main liner in the reservoir or tank. This excess material is held against the external wall of the tank, or tucked in a trench all around the reservoir to support the dam liner in place. It is covered with soil or stones in the trench. Another alternative to trenching is to lay sand bags on it. The weight of the sand bags holds the dam liner in place

After excavation, it is necessary to compress the mould of soil roundabout the water pan before making a trench

See below

Where to buy dam liners in Kenya

How To Weld Dam Liners

- Factory welding. Depending on the dam liner size, weld it whole or partially in the factory. The weight and volume of the welded material must be easily portable on site. The latter factor guides on how much of the dam liner material will be put together in the factory

- Site or field welding. This is done on site at the point of dam liner installation. It is the joining together of the partially welded dam liner pieces from the factory. Site welding is done when the entire dam liner could not be wholly put together in the factory. This is as a result of weight or bulkiness, which limits lifting and transportation of the bulky and heavy material. The weight size of the portable material depends on the thickness of the dam liner. The thicker it is, the less it is

- A wedge welding machine or a heat gun/ heat blower is the equipment that does dam liner welding. A wedge machine is what does it in the factory. The heat gun is highly portable, and so is best for field joinery

Dam liner welding involves melting the liner material under high temperature at the point of joining them. Once melted, the 2 layers are laid one over the other and as they harden, become one unit

Factory wedge welding of a 1mm thick dam liner

Joining 2 dam liner pieces with a heat gun

Both equipment run on electric power. In off grid electricity locations, Grekkon Limited provides a generator to power the heat gun or wedge welding machine

Where to buy dam liners in Kenya

A Step by step procedure on how to install dam liners

To learn how to install dam liners in your water pan or tank, consider the following factors

- Determine if;

1.1. It is a water reservoir

or

1.2 A water tank

Each storage unit has a different way of calculating the dam liner

2. Define the shape of the water pan or tank;

2.1. Is it circular/ oval or square/ rectangular?

2.2 Are the rectangular/ square sides steep or slanted?

The dam liner calculation formulae is different for each shape as illustrated later in this article

The second stage in how to install dam liners is to work out the dam liner size

A Grekkon Limited technician installing a dam liner in a water reservoir

Solar Irrigation Kits In Kenya

Grekkon Limited’s solar irrigation kits in Kenya utilise soalr energy as the primary power source to pump water, and distribute it in the farm. Our solar irrigation kits are a clean energy technology that reduces greenhouse emissions. They substitute fossil fuels as an energy source. The company supplies and installs these kits within the east Africa region mainly for smallholder farmers

A Grekkon solar submersible water pump for smallholder farmers

Solar Irrigation Kits In Kenya

Components

- A water source. This will be a deep or shallow well, a dug out or natural water reservoir, a river, lake or a an artificial water storage unit

- Mounting structure for solar photovoltaic (PV) panels

- A solar pump. This will be either a submersible solar electric water pump (ideal for wells), or a surface solar water pump. The pump will be fixed or portable depending on the size

- A solar water pump controller

- The irrigation system. Most solar powered irrigation systems have the drip irrigation kit as the watering component. This is because it operates under low volume, low pressure. However, some farmers opt also for the rain hose irrigation kit depending on the crop type, available water volume, and the pumping pressure. The rain hose kit works best at high water volume, under high pressure

Components of a solar irrigation kit

Solar Irrigation Kits In Kenya

How they work

- Electricity to run the solar water pump is generated by solar PV panels. They absorb the sun’s energy converting it to direct current (DC) electical energy

- This DC energy flows into an inverter/ controller which converts it to alternating current (AC) electrical energy

- The AC power is channeled to the motor, which runs the pump

- The pump distributes water to the irrigation system

The number of panels used depends on the motor size. The larger it is, the higher the number of PV panels required

A farmer will opt to irrigate by pumping directly to the irrigation system, or to an elevated storage unit, from which the water flows to the irrigation system by gravity

Solar Irrigation Kits In Kenya

Benefits

i. It allows for water pumping in electricity off-grid locations by generating its own solar electric power

ii. It reduces the emissions of greenhouse gases as it does not run on fossil fuels

iii. Farmers produce all your round so long as irrigation water is available

iv. It has near zero maintainance and operating costs, as there’s no drudgery during irrigation

v. There are no opertional costs unlike fossil fuel powered water pumps that require diesel or petrol purchases to run

Solar Irrigation Kit Price In Kenya

Drip Irrigation Kit

| Acreage | Price (Kes) |

| 0.25 | 105,000 |

| 0.5 | 145,000 |

| 1 | 230,000 |

A Grekkon surface solar water pump for irrigation

2. Rain hose kit

| Acreage | Price (Kes) |

| 0.25 | 85,000 |

| 0.5 | 110,000 |

| 1 | 145,000 |

Solar Irrigation Kits In Kenya

FAQs

1. What is a solar power irrigation system?

It is a unit composed of a solar pump, and an irrigation kit

2. Do solar panels work at night?

No they don’t. However, a farmer can choose to set up a battery to store power during the day, to power the irrigation system at night

3. Do solar panels work in the rain?

They work optimally under clear skies. Their efficiency is dramatically reduced with heavy cloud cover

4. How many solar panels does it take to run a water pump?

It depnds on the size of the motor attached to the solar pump. The greater it is, the higher the number of solar panels required

5. What is the weakness of a solar pump?

They do not work if there is no solar energy provision

6. What solar pump is best for agriculture?

Grekkon limited has the best solar powered water pumps for agriculture because they are designed for small, and medium holder farmers in Africa who constitute about 87% of the farmeing community on the continent

7. How long do solar water pumps last?

For more than 20 years with regular servicing

8. Does a solar water pump need a battery?

No. It will work with the current received directly from the solar panels

9. How deep can a solar pump work?

It depends on the head of the submersible solar pump. Some work in wells as deep as 500M

10. Do you need an inverter with solar panels?

Yes if the pump uses AC current. The inverter will convert the DC to AC. However, a DC pump will not require an inverter

Fossil fuel powered water pumps carbon emissions calculation

The downside of fossil fuel powered water pumps is CO2 emissions, which contribute to global warming, the chief reason for negative climate change being experienced today. To calculate the quantity of CO2 emission from a diesel water pump, multiply the fuel usage in litres by a factor of 2.67. For example; a pump that consumes 100 litres of diesel per month emits 267kgs of CO2 emissions monthly. To calculate the quantity of CO2 emission from a petrol water pump, multiply the fuel usage in litres by a factor of 2.3035. For example; a pump that consumes 100 litres of petrol per month emits 230.35 kgs of CO2 emissions monthly.

How To Install Rain Hose Kits

Grekkon Limited’s manual on how to install rain hose kits in Kenya is an easy to read step by step guide. It details every aspect of rain pipe assembly in the farm to provide understanding to farmers. As the pioneer of rain hose kits in Kenya, we are keen to that farmers receive the full benefit of rain pipe irrigation

What is the price of a rain hose irrigation kit?

| Diameter size | Flow rate per 100M | Price in KES |

| 32mm or 1″ | 13 cubic litres per hour | KES 2,500 |

| 40mm or 1-1/4” | 16 cubic litres per hour | KES 5,800 |

| 50mm to 1-1/2″ | 22 cubic litres per hour | KES 6,800 |

Rain hose pipes work under high gravity pressure (from 6M or 0.6bar), and with high volume water pumps. The discharge rate of the water pump is from 40 cubic litres per hour. These water pumps are surface solar, electric, petrol or diesel powered

A well connected rain hose pipe

How To Install Rain Hose Kits

- Trench where the poly vinyl chloride (PVC) main line will be laid. This is not necessary for the high density polyethylene (HDPE) which are surface pipes. PVC pipes are sub-surface pipes because they have no UV-treatment, and will thus degrade easily under the sun. HDPE pipes have UV treatment and will be surface pipes

- Connect the PVC or (HDPE) main line to the water pump or high tank. This pipe evacuates water from the source to the farm and is the largest in diameter. The larger the pipe diameter, the more the water it delivers. .

- Join the HDPE or PVC sub-main line to the main line. The sub-main line is smaller in diameter, and so carries less water. It is joined to the main line through PVC or HDPE accessories such as; tees, elbows, saddle clamps, adaptors or valve sockets

- Connect the rain pipe to the sub-main line or the main line where a sub-main line does not exist. This is done with a rain hose connector or a saddle clamp

- Spread the rain hose along the length, and close the terminal end with an end cap

- Connect one rain pipe to another with a connector

Rain hose fittings from left to right: end cap, connector, rubber, and ball valve

A drilling tool is the only tool used when installing a rain hose kit. This is to create an opening on the main or sub-main line to insert the rain pipe ball valve

How to Install Rain Hose Kits

Components of a rain hose irrigation kit?

1. End-caps. They close the end of the pipe to prevent further water flow

2. Starter off-takes. They connect the rain pipe to the PVC or HDPE main line that supplies water to the rain hose from a water pump or highly elevated water tank

3. Pipe connectors. To connect one rain hose pipe to another

4. Mini valves. To control water flow to the rain hose pipe

The diameter of the pipe are; 25mm, 32mm, 40mm and 50mm. A grower chooses the preferred size based on crop water needs and area of irrigation. For instance, a farmer with 1 acre of the crop will comfortably water with the volume delivered through a 32mm rain hose pipe.

Another grower with 5 acres will better irrigate with a 50mm rain hose pipe. An acre of crop uses 1,000 meters of 25mm, 800 meters of 32mm rain hose pipes, 600M of 40mm pipes, and 400M of 50mm pipes

How To Install rain Hose Kits

Rain hose irrigation system requirements

- The system requires a pressure head of 30M, and above

- When using a water pump to power the rain hose irrigation kit, the discharge rate should be from 45 cubic litres per hour

- The rate of water discharge is determined by the diameter size, and number of pores on the rain pipe. For instance, a rain pipe with 5 holes per cluster discharges less water than the one with 7 holes in a cluster

- It irrigates in opposite directions at a radius of 3M for the 32mm pipe, 5M for the 40mm pipe, and 7M for the 50mm pipe

- The vertical height of this water jet is 1M

Rain Hose Versus Drip Irrigation

- Rain pipes irrigate in an overhead fashion, drip lines irrigate to the root zone

- Drip tapes are water efficient, rain hose kits require large water volume

- Rain pipes have a higher pressure requirement than drip pipes

- Drip lines have emitters, while rain hose kits have pores done with nano technology

- The discharge rate for drip lines is 1.2 to 4 litres per hour per emitter, while the rain hose pore’s is from 7 litres per hour per emitter

- The cost of a drip kit installation per acre is from Kes 100,000, while the rain hose is from Kes 75,000

- The rain hose pipe’s minimum diameter is 25mm/ 3/4″, while drip tape’s is 8mm

Advantages Of A Rain Hose

- water saving and cost effective

- It is easy to install, use and maintain

- Ran hose nanotechnology punched holes are less prone to clogging

- It is used in a broad range of crops

- Rain hose pipes are light and easy to move about

- It irrigates uniformly

- It works under both low gravity and high water pump pressure

Rain hose irrigation system is for the following areas and on these crops

- Crop nurseries; vegetables, fruit trees, forestry

- Short vegetable crops (knee-high and below); cabbage, lettuce, broccoli, kales, spinach, collards, broad beans, carrot, strawberry, and others

- Pasture; grass and legumes

When choosing the crop to irrigate using this method, consider its susceptibility to foliage fungal infections predisposed by leaf surface wetness. Tomato, potato, peppers, peas, green beans, and chili easily succumb to foliage fungal infections when overhead or a rain hose system is used for a long time

Pasture irrigation with a rain hose

How To Install Rain hose Kits

FAQs

a. What is the difference between a rain hose irrigation system and a sprinkler system?

- The technology. The rain pipe irrigation system is designed using nano technology

- The mode of spray. A sprinkler sprays its water in one direction, a rain hose pipe sprays in 3 directions (vertically, horizontally, and diagonally)

- Placement. A sprinkler is placed upright on the surface or sub-surface (for pop up sprinklers). A rain hose is laid on the ground

b. What is the pressure in a rain pipe?

The minimum operating pressure is 30M head / 3 bars

c. What is the spacing for rain hose irrigation?

The distance from one rain pipe to another is from 1.5M depending on the operating pressure, and pipe diameter

Grekkon limited is the largest supplier and installer of rain hose irrigation systems in Kenya, and in the east and central Africa region

Irrigation Company In Nairobi

In 2017 through 2018, Grekkon Limited was an irrigation company in Nairobi servicing small to medium scale holders. The company’s focus was on irrigation and allied services. these are;

- Irrigation. drip, overhead, and sub surface irrigation systems

- Dam liners. for irrigation water harvesting and conservation

- Greenhouses. steaal and wooden types

- Borehole drilling

- Water pumps. solar, electric, petrol and diesel types

- Solar dryers. for post harvest crop loss management

- Agricultural nets. bird nets for bird pests, shade nets for , and insect nets for insect pests

- Trays. seedling trays for seedling propagation, and hydroponic trays for hydroponic fodder production

- Coco peat. a non soil media for use in seedling trays

- Mulch paper. to manage field water loss through evaporation, weed and pest control

While improving the clients’ overall yield, and income from farming. The company focuses on this smallholder, and medium holder niche because of the presence of large irrigation service providers in the country. These companies clientele are the large ornamental, cereal and vegetable growers. Smaller growers had to fend for themselves because they were never a priority for these large corporates. A hallmark of the company is the free 4 month agronomy training programs for all their farmers. Grekkon Limited is the only company that offers this free service to farmers in Kenya

The company organizes ‘training days’ in various regions of the country. Growers come to learn of new and existing technologies.

The other objective was to do further by offering expert irrigation, greenhouse, water pumps, and dam lining expertise to these small scale to medium scale commercial farmers, who had no professional entity to consult for such. This was through physical site visits to carry out assessments, provide advice, and carry out irrigation project reviews afterwards. And so, Grekkon Limited – Irrigation Hub was born. It is headquartered in Athi River, with outlets in other key agricultural zones in Kenya

Two years after establishment, Grekkon won the coveted Most Preferred Irrigation Systems Company of the Year award in 2019. This was at the prestigious Agribusiness Excellence Awards ceremony. The farmers in their votes had finally spoken!

Irrigation Company In Nairobi

1. Irrigation Products

- Drip kits. For both vegetable and fruit tree/ forestry irrigation. This includes; drip tape, 16mm HDPE pipe, starter connectors, off-takes, drip to drip connectors, button or online drippers, and end caps

- Rain hose kits. It has; rain hose pipe, off-takes, connectors, and an end cap. Rain hose kits are best utilised where drip irrigation systems cannot be installed such as is pasture, or crop nurseries

- Sprinkler systems. There are various types;

3.1. Pop up sprinklers. These are sub-surface sprinklers for lawns, golf course, football pitches, and gardens

3.2. Rain gun sprinklers. These are metallic high pressure, high volume sprinklers for use in all crops. They are well utilised in larger acreage because they have a wide area of spray

3.3. Impact sprinklers. They are plastic and range from 1/2″ to 1″. Mostly used to irrigate small vegetable farmes, or pasture

3.4. Meganet sprinklers. These are plastic sprinklers that range from 1/2” to 1”. They are a suitable alternative to impact sprinklers

3.5. Butterfly type sprinklers. They are for lawns and small gardens like the kitchen garden

3.5. Micro sprinklers. They irrigate individual fruit tree plants, just like button drippers. However they cover a wider area, and provide better humidity around the crop’s root zone

In this video below, a smallholder farmer who was an early adapter of Grekkon’s rain hose kits. She speaks about her growing experience

4. Misters and foggers. Used in greenhouses for seedlings watering, and humidity control

Solar water pumps by Grekkon Limited

5. Water pumps;

As an irrigation equipment supplier, every irrigation system is backed by the following types of water pumps to draw water from a source, to supply the irrigation system

i. Solar water pumps. These are either surface or submersible types. Submersible water pumps work under water, while surface water pumps are ground based

ii. Electric water pumps. Like solar water pumps, they’re surface and submersible options

iii. Diesel generator water pumps. They run on diesel powered engines. They are portable or fixed types. The latter are larger in size

iv. Petrol water pumps. They run on petrol powered engines, and are smaller than diesel water pumps

6. Irrigation pipes

6.1. HDPE pipes from 16mm through 280mm diameter. The pipe thickness is from PN6 through PN25

6.2. PV pipes from 20mm through 280mm diameter. The pipe thickness is from PN6 through PN25

6.3. Suction pipes for supply with water pumps

6.4. Delivery pipes as either canvass or PVC material

Irrigation Company In Nairobi

Water pump accessories

Accessories that accompany motor powered pumps are; foot valves, clips, suction pipes, adaptors, splicing kits, control boxes, invertors (for DC to AC converstion) cables, cable ties, solar panels (for solar pumps), and a solar panel support structure

Accessories that accompany motor powered pumps are; foot valves, clips, suction pipes, and adaptors

Every irrigation system has a main, and/ or sub-main pipes. We advice on the right pipe thickness, size and type based on

- Land size; determines pipe size. Large pipes for large acreage. Our pipe sizes range from 16mm to 180mm in diameter

- Irrigation system adopted; any of the 1 to 3 above

- Land ownership system; leased or owned? HDPE for the former, PVC for the latter

These pipes have specific fittings which are; elbows, tees, valve sockets, ball valves, couplings, adaptors,sockets,saddle clamps, and end caps by type and size

Drip irrigation system under installation by Grekkon Limited using PVC pipes as main and sub-main lines

Irrigation Company In Nairobi

Installation Service

Our irrigation service team conducts systems installations service in east Africa. We offer advisory services to manage the system well for many years

A client’s irrigation system installation by a company technician

Irrigation Company In Nairobi

Key Attributes

Innovation

Grekkon Limited in its innovation introduced the rain hose irrigation system. This new product solved many irrigation challenges for commercial vegetable and corn farmers. The company is the market leader in research and commercialization of natural solar dryers, each unit designed to meet the product or market drying requirements

Today, Grekkon Limited is the largest supplier of natural solar dryers within the east Africa community states

In 2024, Grekkon Limited introduced the first color coded drip tapes in the Kenyan market

Team

Grekkon Limited’s resounding success is largely due to its team of field professionals who provide engineering, commercial, and technical services

Country Wide Presence

As an major irrigation company in Kenya, Grekkon Limited has offices in; Athi River, Nairobi, Kisumu, Eldoret, Nyeri, and Nyahururu

Metallic Greenhouse Price In Kenya

Every metallic greenhouse price in Kenya by Grekkon Limited is determined by the greenhouse type, and size. All metallic greenhouses in Kenya by the company are made from galvanised steel. They are built to last for decades under intense crop production

Metallic Greehouse Price In Kenya

Our metallic greenhouse price in Kenya is provided in the tabulations below by cost and size for galvanized metallic greenhouse tunnel-type structures. Each unit has a drip irrigation kit, side roll-ups, and an entry pouch. We offer a crop support structure, a 1,000L tank, PPE kits, fertilizer, and seeds package at an extra cost. Consideration is made for a grower’s greenhouse budget. These prices include all greenhouse materials in Kenya

Completed units of metallic greenhouses by Grekkon Limited in Heni area, Nyandarua county

How much does a metallic greenhouse cost in Kenya?

A. Small

| Dimensions in meters | Tomato Crop Population | Price in KES |

| 15 x 8 | 600 | KES 195,000 |

| 24 x 8 | 800 | KES 275,000 |

| 30 x 8 | 1,200 | KES 365,000 |

| 40 x 8 | 1,500 | KES 530,000 |

| 48 x 8 | 1,600 | KES 600,000 |

B. Medium

| Dimensions in meters | Tomato Crop Population | Price in KES |

| 24 x 16 | 1,500 – 1,600 | KES 540,000 |

| 30 x 16 | 2,400 | KES 660,000 |

| 40 x 16 | 3,000 | KES 990,000 |

C. Large

From 800M square. Kes 900 per meter square. We customise our price according to size, and your greenhouse budget

Metallic Greenhouse Price In Kenya

5 Key Factors That Determine Greenhouse Cost

- unit size. The larger it is, the costlier it becomes for the reason that it take in more material and labour. The choice a greenhouse of size is determined by; land area, water availability, and a grower’s budget

- design. A tunnel type greenhouse is less costly than a vented type. This is because the latter has a larger roof surface area. Tunnel type greenhouses are for cooler highland locations, while the vented types are for warmer mid to low altitude areas. co-joined units are less costly than single units. For intance, 3 units measuring 30M x 8M built separately are more expensive than contructing them as one co-joined unit measuring 30M x 24M

- greenhouse construction frame material of the unit. Grekkon Limited as a top greenhouse construction company in Kenya, has an option of a low cost greenhouse constructed from timber. This is referred to as a wooden greenhouse, or the option of the more pricey metallic greenhouse. Both serve the same purposes

- frame treatment undertaken. Timber for greenhouse construction in Kenya is either treated with light organic solvent preservative (LOSP), or with used motor oil. These treatments protect the timber from termite attack. LOSP treatment is costlier, and preserves the wood longer. Motor oil has to be re-applied every so often and should not be in contact with the crop. Steel is either galvanised with zinc, or an aluminum paint coat is applied on the surface. In this too, the former treatment is costlier, and remains for long

- greenhouse crop type. our greenhouse construction cost in Kenya for each of these types is determined by the crop type. For instance, an indeterminate crop that requires an internal crop support system will have a more costly greenhouse than a short strawberry crop. The greenhouse installation cost of a plant propagation unit with misters and foggers is higher than a herbs and spices unit without such

Metallic Greenhouse Price In Kenya

These are the materials used in metallic greehouses in Kenya installations

I. UV treated greenhouse polythene with anti drip properties

This is the key material that protects the crop from the elements of weather; sun, wind and rain. It creates the ‘greenhouse effect’, and minimises disease and pest incidences on the crop. It is either clear or yellow in color. Clear greenhouse polythene for fruiting crops, or in ornamentals, bi or multi colors. This is because it allows in more light which these need for photosynthesis, the process that makes food for the plants. Yellow is for vegetative crops, and mono color ornamentals. In mono color ornamentals, it intensifies the color

II. Galvanised steel bars

They provide structural support to the greenhouse, and also to the crop as ‘crop support structures’ for tall indeterminate crops such as; tomato, peppers, and cucumbers

III. UV treated high density insect nets

These nets keep away insect pests. They are for self pollinating (do not require external pollinators such as insects and birds) greenhouse crops

IV. Bird nets

These are only used in greenhouse crops that require insect pollination from bees, butterflies, hornets and many other pollinating insects. They allow in the insects, but keep away bird pests. An example of such a crop is strawberry

V. Profiles

They are screwed onto the galvanised steel bars so that the greenhouse cover is tucked in them

VI. Wiggle wires

Once the greenhouse cover is tucked in the profile, wiggle wires keep it in place so that it is not removed by wind or other physical force. Wiggle wires have a plastic covering to prevent damage to the greenhouse paper the are in direct contact with

Wiggle wires hold in place a clear greenhouse polythene sheet tucked in a profile

VII. Screws

The join the profiles to the galvanised steel structure

VIII. Concrete

This is what supports the metallic greenhouses in Kenya structures on the ground and keeps them upright

Humidification through misters in a seedlings propagation greenhouse

Successful greenhouse farmers in Kenya grow both none food and food crops in our metallic greenhouses. Common greenhouse food crops are; tomato, peppers, strawberries, and cucumber. Galvanised steel bars, insect netting, screws, and profiles are our greenhouse construction materials. With labor addition, all now constitute your final greenhouse cost

Grekkon Limited’s metallic greenhouse price in Kenya will include; a drip irrigation system for crop production, or a misting/ fogging system for seedlings propagation, and labour. Sprinkler irrigation systems are not installed in greenhouses

A bird’s eye view of a metallic greenhouse for seedlings propagation under construction by Grekkon Limited at the ICIPE institute in Kasarani area, Nairobi county