Types of Irrigation Pipes In Kenya

Grekkon Limited supplies and installs various types of irrigation pipes in Kenya. These pipes are of different diameter sizes, lengths, and wall thickness. The larger the pipe diameter, the more volume of water it carries, and the lesser the frictional losses. With a longer pipe, a grower requires less connections between pipes. Wall thickness determines the amount of water pressure a pipe will withstand. The thicker the wall, the greater the water pressure withstood. It is indicated as pressure nominal (PN), with a number. The higher the number the thicker the walls

Types of Irrigation Pipes in Kenya

1. HDPE pipes (High density polyethylene pipes)

They are black in colour and are manufactured as rolls of 100M for these diameter sizes below

16mm, 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, and 90mm.

Larger then 90mm, we supply them as 50M rolls. Grekkon Limited’s HDPE pipes are UV treated for surface application. They have a long lifespan because they are not easily degraded by the sun when exposed.

16mm HDPE pipes

HDPE Pipe prices in Kenya

| Size in MM | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 | Length (M) |

| 16 | 17.00 | 17.00 | 100M | |||||

| 20 | 25 | 28 | 31 | 33 | 36 | 41 | 49 | 100M |

| 25 | 34 | 36 | 40 | 46 | 52 | 64 | 74 | 100M |

| 32 | 49 | 49 | 59 | 71 | 86 | 101 | 120 | 100M |

| 40 | 61 | 76 | 90 | 112 | 132 | 157 | 187 | 100M |

| 50 | 95 | 115 | 139 | 169 | 206 | 243 | 289 | 100M |

| 63 | 151 | 178 | 222 | 269 | 324 | 390 | 454 | 100M |

| 75 | 207 | 255 | 313 | 382 | 453 | 547 | 648 | 100M |

| 90 | 300 | 364 | 450 | 547 | 657 | 789 | 930 | 100M |

| 110 | 441 | 548 | 669 | 810 | 974 | 1,170 | 1,394 | 50M |

| 125 | 568 | 700 | 854 | 1,044 | 1,264 | 1,514 | 1,793 | 50M |

| 140 | 716 | 876 | 1,073 | 1,307 | 1,575 | 1,898 | 2,254 | 50M |

| 160 | 940 | 1,149 | 1,399 | 1,706 | 2,063 | 2,472 | 2,932 | 12M |

| 180 | 1,171 | 1,444 | 1,770 | 2,165 | 2,614 | 3,126 | 3,706 | 12M |

| 200 | 1,451 | 1,789 | 2,183 | 2,655 | 3,223 | 3,866 | 4,584 | 12M |

| 225 | 1,824 | 2,168 | 2,771 | 3,372 | 4,080 | 4,895 | 5,797 | 12M |

| 250 | 2,254 | 2,767 | 3,395 | 4,153 | 5,017 | 6,015 | 7,154 | 12M |

| 280 | 2,819 | 3,492 | 4,265 | 5,205 | 6,291 | 7,560 | 8,972 | 12M |

| 315 | 3,592 | 4,389 | 5,401 | 6,596 | 7,963 | 9,562 | 11,358 | 12M |

| 355 | 4,538 | 5,573 | 6,875 | 8,363 | 10,108 | 12,147 | 14,401 | 12M |

| 400 | 5,755 | 7,106 | 8,688 | 10,605 | 12,833 | 15,408 | 18,288 | 12M |

| 450 | 7,277 | 8,987 | 11,007 | 13,433 | 16,251 | 19,507 | 23,137 | 12M |

| 500 | 8,976 | 11,087 | 13,601 | 16,576 | 20,052 | 24,038 | – | 12M |

| 560 | 11,252 | 13,877 | 17,038 | 20,796 | 25,120 | 30,158 | – | 12M |

| 630 | 14,257 | 17,529 | 21,579 | 26,285 | 31,828 | 38,163 | – | 12M |

2. PVC Pipes (Polyvinyl chloride pipes)

PVC pipes are 6M long, come in different diameter and wall thickness sizes. They have no UV treatment and are thus for sub-surface irrigation application.

PVC Pipes by Grekkon Limited

PVC Pipe Prices in Kenya

| Size in MM | PN6 | PN8 | PN10 | PN12.5 | PN16 |

| 379 | |||||

| 425 | 532 | ||||

| 32 | 553 | 588 | 694 | 795 | |

| 40 | 698 | 744 | 877 | 1093 | 1220 |

| 50 | 935 | 1,162 | 1,383 | 1705 | 1760 |

| 63 | 1,475 | 1,833 | 2,177 | 2722 | 3359 |

| 75 | 2,024 | 2,529 | 3,111 | 3839 | 4702 |

| 90 | 2,955 | 3,664 | 4,459 | 5527 | 6755 |

| 110 | 3,508 | 4,388 | 5,951 | 6717 | 8260 |

| 140 | 5,782 | 7,060 | 8,795 | 10805 | 13229 |

| 160 | 7,295 | 9,195 | 11,536 | 14189 | 17032 |

| 200 | 11,566 | 14,538 | 17,915 | 22116 | 27086 |

| 225 | 14,610 | 18,210 | 22,521 | 27991 | 34312 |

3. Delivery/ Lay-flat pipes

They are highly flexible irrigation water pipes made from UV treated PVC material.They are supplied as 30M, 50M or 100M long. The diameters are 2″ and 3″, with thicknesses of PN6, PN8 1nd PN10. These pipes are designed for surface use.

In sprinkler irrigation systems, they are connected to a water pump, or a HDPE or PVC pipe main line, then to a water sprinkler. In drip irrigation systems, it will be a main, or sub main line

Delivery/ Lay-flat pipe

4. Drip Irrigation Pipes

These are 0.3mm, 0.4mm, and 1mm thick pipes with a 16mm diameter. They are the lateral that deliver water to the base of the crop. The 0.3mm and 0.4mm are for vegetable crops, while the 1mm are for hedges and orchards. They all have pre-perforated emitters spaced at 15cm, 20cm, or 30cm. The choice of emitter spacing depends on the crop type; 15cm for closely spaced crops like onion and garlic, 20cm for moderately spaced crops like tomato, and cabbage. 30cm is for further spaced crops

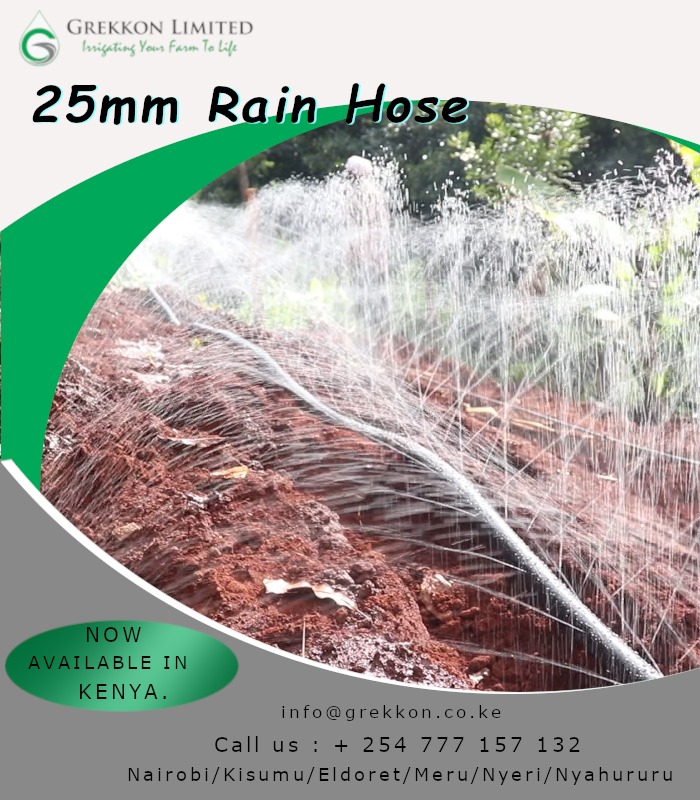

5. Rain Hose Pipes

Rain hose irrigation system with nanotechnology punched holes is an affordable irrigation system for overhead irrigation. Rain hose irrigation system uses nano technology to convey water to the plant. It has a series of holes spaced at intervals which sprays water flow by high gravity, or from a water pump is initiated. Our 0.5mm thick, 100M long rain hose pipes are UV treated to last for 10 years in use

Features of a rain hose irrigation system

- It simulates natural rainfall by delivering water to the base of the crop, with the right droplet sizes

- The overhead water is discharged in a 3 dimensional manner; vertically, horizontally, and diagonally

- It is connected directly to a main line

- It is not easily blocked as the water is delivered under high pressure

- The operating pressure is from 15M head / 1.5 bar

Advantages of Grekkon rain hose irrigation pipes

- It is easy to install and maintain, and more economical to install than sprinklers

- It has anti-UV treatment, so it is not easily degraded by the sun

- These spray holes are made with nanotechnology to ensure uniform flow of water

- Irrigate both under gravity flow, and high water pump pressure

- Irrigate an area in just 10 minutes

- Highly portable

- A variety of diameters to select from depending on the farm size

Downsides of a rain hose system

- It is less water efficient compared to drip irrigation

- Water loss due to evaporation

- It cannot be used on crops, for intance, crops that are highly susceptible to fugal infections due to foliage wetness

- It requires high operating pressure

- Rainhose are more prone to clogging than large sprinklers because the have tiny emitters

- Under extremely high pressure, the pipes get damaged

Ideal crops for rain hose irrigation system

Crops that can be irrigated using the grekkon rain hose are:

- Vegetable such as carrots, brassicas, potatoes

- Closely spaced bulbs such as onion and garlic

- Fruit tress; avocado, pixie orange, macadamia, coffee

- Agro forestry

- Lawns, gardens, pasture, and football pitches

They are idea for tree or vegetable nursery irrigation

Types of Irrigation Pipes In Kenya

How to select your irrigation pipe

- Farm ownership method. A leased farm will have the surface HDPE pipes which will be disconnected when the lease period expires. A permanent farm will have sub-surface PVC pipes

- Irrigation method. Drip and rain hose kits will have HDPE and PVC as the main and sub main line often times. Sprinkler systems are best done with delivery pipes due to sprinkler movement in the farm

- Farm size. A larger farm will have larger diameter pipes because more water is needed to irrigate

- Pressure type. Irrigation water flow by gravity is through less thicker pipes such as PN6 or PN8

Types Of Dam Liners

As a dam liner company, Grekkon Limited supplies and installs 3 types of dam liners in Kenya by thickness, and 2 types of dam liners by material. In this article, we answer many water harvesting using dam liners questions posed to us by growers

1. What type of dam liner is best?

1.1. Types of dam liners in Kenya – by material

High density polyethylene (HDPE) dam liners

This is what we supply and install most. This is because it is thin and lightweight which makes it easy to carry. They are tough with high tensile strength, hard to puncture, and stiff, which makes them less prone to sudden length tears. However, this stiffness makes welding more difficult. HDPE dam liners have the best UV resistance, and are safe for the environment because they do not emit chemicals. Their disadvantage is that they’re more difficult to repair when perforated. Our HDPE dam liners are in rolls from which we cut and tailor weld it to a water pan’s specifications

A HDPE dam liner installed by Grekkon Limited in Vihiga county, Kenya

Polyvinyl chloride (PVC) dam liners

We supply and install these but at a lessor scale. PVC dam liners are highly flexible, impermeable and tough. They are heavier than HDPE dam liners, but easier to weld as the material joins together more easily. They have the best resistance to chemicals and acids and so they are not easily corroded. This makes them the most suitable for land fills and chemical containment sites. Our PVC dam liners are factory fabricated panels that eases installation. The downside with PVC dam liners is environmental safety because they release chemicals as the PVC material degrades. This in the long-term is toxic to fish

A PVC dam liner installed by Grekkon Limited in a water pan in Kibwezi, Kenya

Low density polyethylene (LLDPE) dam liners

They are made from the same plastic as HDPE dam liners, and so share similarities. Being less dense than their HDPE cousins, they are softer, more flexible and more pliable. Being softer makes them less susceptible to stress cracking. High flexibility allows for easier under installation, and molding them around corners, nooks and crannies. Pliability means they conform best to rough terrain with little wrinkles

An LLDPE liner in a large water pan

1.2. Types of dam liners in Kenya – by thickness

- 0.5mm / 500 microns. This is for smooth surfaces and to hold low water volume (5,000 cubic liters and below)

- 0.75mm / 750 microns and 0.8mm / 800 microns. Works well in rough surfaces with few stones or murram. It will hold medium water capacity

- 1mm / 1,000 microns. Best for stony or rocky surfaces, and high capacity

- 1.5mm / 1,500 microns. Works on surfaces that the 1mm will not, and holds ultra high water volumes

2. Which is better: PVC or HDPE dam liner?

HDPE is better because it has greater tensile strength, and does not contaminate the environment

3. What is a good thickness for a dam liner?

The choice of thickness is determined by the surface and water volume. For instance, a 0.5mm dam liner is more appropriate for a concrete water tank holding 100 cubic litres than a 1mm dam liner

4. What are the 2 main types of dam liners?

HDPE and PVC dam liners are the most common dam liners in Kenya

5. How long does a dam liner last?

This depends on the thickness, material type and use. As a guideline though, 0.5mm thick dam liners last to 15 years, 0.75mm to 25 years, and 1mm to 36 years

6. Can I put a new dam liner over an old one?

The simple answer is yes, but remove any liquid, and solid debris on the old liner’s surface. Note that once the new one is placed, you cannot shift the old liner without affecting the new one. The new dam liner is not joined to the old dam liner in any way

7. How often do dam liners need to be replaced?

So long as the dam liner is functioning well, it is unnecessary to remove it. There is no replacement timeline

8. What is the best liner for a large water pan?

Large is relative. But for any water reservoir holding beyond 5,000 cubic litres, we recommend the 0.75mm or the 1mm thick dam liners

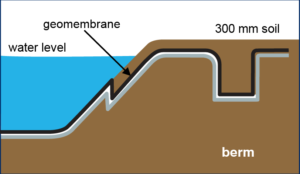

9. How do you hold a dam liner in a water pan?

There are 2 ways.

9.1. Trenching

This is where a 2 feet deep by 1 foot wide trench is excavated all round the circumference of the water reservoir. This trench is 0.75M to 1M from the edge of the water pan. The dam liner is tucked in here then covered with soil, gravel or rocks/ stones

The edges of a newly installed HDPE dam liner in a water pan tucked in a trench and covered with soil

9.2. Sand bags

Bags filled with soil, sand or gravel are laid on top of the dam liner edges to anchor it in place

The different types of dam liners does not affect the holding method

10. Can you join 2 dam liners together?

Yes. Pieces of dam liner welded together make a continuous sheet

11. Can you glue 2 dam liners together?

The best way to join dam liners is by welding because it is permanent

12. Can you cut a dam liner?

Yes. We cut and weld together dam liner sheets from large rolls to tailor it to the water pan’s dimensions

13. Can you put gravel on top of a dam liner?

Yes you can especially if it is for support on the edges

What to consider when choosing a dam liner

- The surface texture. Install a thicker liner for rougher surfaces

- Water volume. The larger it is, the thicker the dam liner

- Purpose. If it will hold chemicals or acids, then the PVC dam liner is best because it is the most resistant

Rain Hose Pipe Price

Grekkon Limited’s rain hose pipe price is by diameter size. Our rain hose for sale in Kenya is attached to a HDPE, PVC, or delivery/ lay-flat irrigation main or sub-main line when in the farm. These rain hose pipes are made from HDPE material with UV treatment for use in tropical climates.

Rain Hose Pipe Price Kenya

| Diameter size | Flow rate per 100M | Diameter of spray at 50M Head | Price in KES |

| 32mm or 1″ | 13 cubic litres per hour | 6M | KES 2,500 |

| 40mm or 1-1/4” | 16 cubic litres per hour | 8M | KES 3,500 |

| 50mm to 1-1/2″ | 22 cubic litres per hour | 9M | KES 4,500 |

Rain Hose Pipe Price

Rain hose Vs drip irrigation

| Rain hose pipe | Drip irrigation pipe | |||||||

| 1 | Set up cost per acre is from Kes 45,000 | Set up cost per acre is from Kes 90,000 | ||||||

| 2 | Has holes punched with nano technology | Has a drip emitter | ||||||

| 3 | Has many holes per section | Has a single or double drip emitter per section | ||||||

| 4 | Irrigation rate is from 13 cubic litres per hour per 100M length | Irrigation rate is from 8.5 cubic litres per hour per 100M length | ||||||

| 5 | Has thicker (0.5mm) walls so lasts longer | Has thinner walls (0.3mm or 0.4mm) so a shorter lifespan | ||||||

| 6 | Diameter size is from 32mm to 50mm | Diameter size is 16mm | ||||||

| 7 | Maximum pipe length is 100M | Maximum pipe length is 1000M | ||||||

| 8 | Irrigates aerially using sprays | Irrigates to the ground via small drops |

| 9 | Easy to move from section to section in the farm | They are permanently set in one section |

The rain hose pipe price is not a good cost comparison to either drip or sprinkler irrigation. Rather, consider the set up and operational cost per acre under each method of irrigation Rain hose works well with crops that thrive under sprinkler irrigation. Examples are; onion, garlic, cabbage, traditional vegetables, leafy vegetables and others. Crops that are susceptible to fungal infections if the leaves remain wet for long are irrigated with drip. Examples are; green beans, potato, strawberry, tomato, capsicums, peppers and others

Rain Hose Pipe Price

What are the other components of a rain hose irrigation kit?

1. End-caps. They close the end of the pipe to prevent further water flow 2. Starter off-takes. They connect the rain pipe to the PVC or HDPE main line that supplies water to the rain hose from a water pump or highly elevated water tank 3. Pipe connectors. To connect one rain hose pipe to another 4. Mini valves. To control water flow to the rain hose pipe

The diameter of the pipe are; 25mm, 32mm, 40mm and 50mm. A grower chooses the preferred size based on crop water needs and area of irrigation. For instance, a farmer with 1 acre of the crop will comfortably water with the volume delivered through a 32mm rain hose pipe.

Another grower with 5 acres will better irrigate with a 50mm rain hose pipe. An acre of crop uses 1,000 meters of 25mm, 800 meters of 32mm rain hose pipes, 600M of 40mm pipes, and 400M of 50mm pipes

Rain Hose Pipe Price

Irrigation system requirements

- The system requires a pressure head of 30M, and above

- When using a water pump to power the rain hose irrigation kit, the discharge rate should be from 45 cubic litres per hour

- The rate of water discharge is determined by the diameter size, and number of pores on the rain pipe. For instance, a rain pipe with 5 holes per cluster discharges less water than the one with 7 holes in a cluster

- It irrigates in opposite directions at a radius of 3M for the 32mm pipe, 5M for the 40mm pipe, and 7M for the 50mm pipe

- The vertical height of this water jet is 1M

Irrigating a newly transplanted crop with a rain hose pipe

Rain Hose Pipe Price

How to assemble a rain hose irrigation system kit

1. Lay the mainline

This is the pipe delivering irrigation water to the farm from the pump. Your mainline will be larger in size than the rain hose pipe. So if your rain hose pipe is 1” for instance, use a 1.5” or 2″ main or sub mainline

2. Connect to the mainline

Make a 1” insertion on the mainline and attach the off-take connector. The size of the insertion is as per the size of your off-take3. Rain pipe connection

Attach the rain hose pipe to the off-take connector4. Hose to hose connection

Use the connector to attach one rain hose to another5. End cap

Insert the end cap at the end of the hose

Rain Hose Pipe Price

Target areas and crops

- Crop nurseries; vegetables, fruit trees, forestry

- Short vegetable crops (knee-high and below); cabbage, lettuce, broccoli, kales, spinach, collards, broad beans, carrot, strawberry, and others

- Pasture; grass and legumes

When choosing the crop to irrigate using this method, consider its susceptibility to foliage fungal infections predisposed by leaf surface wetness. Tomato, potato, peppers, peas, green beans, and chili easily succumb to foliage fungal infections when overhead or a rain hose system is used for a long time

Pasture irrigation with a rain hose

Rain Hose Irrigation Versus Drip Irrigation

- Rain pipes irrigate in an overhead fashion, drip lines irrigate to the root zone

- Drip tapes are water efficient, rain hose kits require large water volume

- Rain pipes have a higher pressure requirement than drip pipes

- Drip lines have emitters, while rain hose kits have pores done with nano technology

- The discharge rate for drip lines is 1.2 to 4 litres per hour per emitter, while the rain hose pore’s is from 7 litres per hour per emitter

- The cost of a drip kit installation per acre is from Kes 100,000, while the rain hose is from Kes 75,000

- The rain hose pipe’s minimum diameter is 25mm/ 3/4″, while drip tape’s is 8mm

Advantages Of Rain Hose Irrigation

- water saving and cost effective

- It is easy to install, use and maintain

- Ran hose nanotechnology punched holes are less prone to clogging

- It is used in a broad range of crops

- Rain hose pipes are light and easy to move about

- It irrigates uniformly

- It works under both low gravity and high water pump pressure

Rain Hose Pipe Price

FAQsa. What is the difference between a rain hose irrigation system and a sprinkler system?

- The technology. The rain pipe irrigation system is designed using nano technology

- The mode of spray. A sprinkler sprays its water in one direction, a rain hose pipe sprays in 3 directions (vertically, horizontally, and diagonally)

- Placement. A sprinkler is placed upright on the surface or sub-surface (for pop up sprinklers). A rain hose is laid on the ground

b. What is the pressure in a rain pipe?

The minimum operating pressure is 30M head / 3 barsc. What is the spacing for rain hose irrigation?

The distance from one rain pipe to another is from 1.5M depending on the operating pressure, and pipe diameterGrekkon limited is the largest supplier and installer of rain hose irrigation systems in Kenya, and in the east and central Africa region. It offres the most affordable rain hose pipe prices

Pop-Up Sprinkler Kits In Kenya

Grekkon Limited’s pop-up sprinkler kits in Kenya are designed for lawns and gardens. As a lawn irrigation company in Kenya, we design your lawn irrigation system layout, then install your pop up sprinklers. Our pop-up sprinklers have inlet sizes of; 1/2″, and 3/4″. This inlet size determines the amount of water discharged, and the pop up sprinkler radius

Components of a Lawn Irrigation Kit

- Electric surface water pump. The size of the electric water pump, and motor power is determined by the area under irrigation

- HDPE pipe; your HDPE pipe diameter size is from 32mm (1″) in diameter to 63mm/ 2″ depending on the size of the area under irrigation. The pipe’s thickness is PN8 through PN16 depending on the pressure power of the electric water pump

- HDPE fittings; 32mm (1″) tees, elbows, adaptors and end caps. They connect the HDPE pipe to the water pump, to each other, and to the pop-up sprinklers

- Timer. This is for an automated system. It switches the pop-up sprinkler irrigation system on and off according to the timings set

Pop-up Sprinkler Kits Price In Kenya

Pop-up Kit Prices Tabulation

Area In Meters Square Number of Pop up Sprinklers Pop up Sprinkler Inlet Size Cost In Kes 50 1 1/2″ 12,000 100 1 3/4″ 18,000 500 (1/8 acre) 5 3/4″ 75,000 1,000 (1/4 acre) 9 3/4″ 125,000

The given pop-up sprinkler kits cost includes an electric water pump

Types of Pop-Up Sprinklers

There are 2 types of pop-up sprinklers by Grekkon Limited

Spray irrigation heads

Spry irrigation heads have a working pressure of 14M to 20M head. They they are for small to medium sized spaces. Each is placed at a maximum distance of 4.5M from each other. Spray irrigation heads give out a fine mist, fast, and irrigate evenly. They are not recommended on windy days or windy locations

Spray irrigation head pop up sprinklers

Spray rotary heads

They are rotary with a working pressure from 20M head, and are for medium to large spaces. This is because they deliver water slowly in a stream, instead of a fine mist. Spray rotary heads are good for slow draining soils and slopes. Their spacing is from 6M

Spray rotary head pop-up sprinkler

Pop-Up Sprinklers Spacing

As shown above, the sprinkler spacing is a factor of the type of sprinkler, and also the size. Sprinklers’ spray will overlap to avoid ‘dry blind spots’

The spray jet from each sprinkler should extend to the other sprinkler for full coverage

The spray jet from each sprinkler should extend to the other sprinkler for full coverage

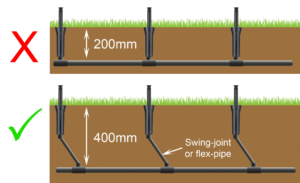

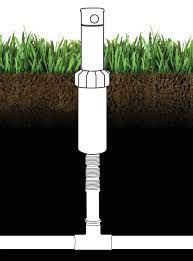

How To Install Pop-Up Sprinklers

Our sub-surface pop-up sprinklers kit is piping is 40cm below ground level as illustrated below

The sprinklers have laterals to a HDPE main line. This pipe’s diameter is according to the amount of water needed

The laterals from the main line carry water to the sprinklers. This depth secures the pipes against damage from the surface

Steps To Repair A Pop-up Sprinkler Head

When pop-up sprinklers age, the heads will sometimes, get stuck in position so it doesn’t rotate, chip or break. If this oocurs, follow these steps below to fix your pop-up sprinkler head

- Cut out a circular area around the pop-up sprinkler, about 15cm to 20cm in diameter

- Remove the intact grass around the sprinkler. This way, you’ll return it as it was after the repairs to the same location

- Unscrew the faulty sprinkler from it’s rider

- Replace the old head with a new one of a similar size

- Screw back the new sprinkler

- Adjust the new sprinkler head to direct the spray where you need it

- Turn on the water to test the new sprinkler, to remove any dirt/ debris, and to check for any leakages on your new connection

- Return the cut out grass

Pop-up Sprinkler Kits In Kenya

FAQs

1. How deep do pop-up sprinklers need to be?

Not more than 40cm below surface. This avoids accidental punctures of the pipe, and allows easy assessment or improvement

2. How many pop-up sprinklers can you put on one zone?

The number of pop-up sprinklers installed by Grekkon Limited in a unit area are a factor of;

2.1. Pop-up sprinkler inlet diameter/ size. The larger the diameters, the lessor the units needed

2.1. Water pump size. The larger it is, the more sprinklers it runs per unit area

2.3. Location factors. presence of obstacles such as trees, rocks, hedges and so on

3. How long should you run pop-up sprinklers?

This depends on the discharge rate of the sprinkler. The 9L per minute sprinklers need 15 to 20 minutes to completely water a section. The 2.5L per minute ones need an hour

4. How much water does a pop-up sprinkler use per minute?

The average is 5.5 litres

5. What height should pop-up sprinklers be set at?

10cm above ground when irrigating

6. How much pressure do pop-up sprinklers need?

This is 20M to 35M head

7. Can you mow over pop-up sprinklers?

Yes you will mow over it, but have the motor off

A pop up sprinkler timer installed for a project at Vipingo, Kilifi county

Small Irrigation Equipment Supplier

Grekkon Limited is a small irrigation equipment supplier in east Africa. Domiciled in Kenya, we serve farmers in; Cameroon, DRC, Ethiopia, Kenya, Nigeria, Rwanda, Somalia, South Sudan, Tanzania, Uganda and Zambia.

Our irrigation materials, tools and equipment vary with the system adopted by a grower. Below is our irrigation equipment list

Double emitter drip tapes pioneered in Kenya by Grekkon Limited

Small Irrigation Equipment Supplier

Types of Irrigation Equipment

- Drip kits. For both vegetable and fruit tree/ forestry irrigation. This includes; drip tape, 16mm HDPE pipe, starter connectors, off-takes, drip to drip connectors, button or online drippers, and end caps

- Rain hose kits. It has; rain hose pipe, off-takes, connectors, and an end cap. Rain hose kits are best utilised where drip irrigation systems cannot be installed such as is pasture, or crop nurseries

- Sprinkler systems. There are various types;

3.1. Pop up sprinklers. These are sub-surface sprinklers for lawns, golf course, football pitches, and gardens

3.2. Rain gun sprinklers. These are metallic high pressure, high volume sprinklers for use in all crops. They are well utilised in larger acreage because they have a wide area of spray

3.3. Impact sprinklers. They are plastic and range from 1/2″ to 1″. Mostly used to irrigate small vegetable farmes, or pasture

3.4. Meganet sprinklers. These are plastic sprinklers that range from 1/2” to 1”. They are a suitable alternative to impact sprinklers

3.5. Butterfly type sprinklers. They are for lawns and small gardens like the kitchen garden

3.5. Micro sprinklers. They irrigate individual fruit tree plants, just like button drippers. However they cover a wider area, and provide better humidity around the crop’s root zone

In this video below, a smallholder farmer who was an early adapter of Grekkon’s rain hose kits. She speaks about her growing experience

4. Misters and foggers. Used in greenhouses for seedlings watering, and humidity control

Solar water pumps by Grekkon Limited

5. Water pumps;

As an irrigation equipment supplier, every irrigation system is backed by the following types of water pumps to draw water from a source, to supply the irrigation system

i. Solar water pumps. These are either surface or submersible types. Submersible water pumps work under water, while surface water pumps are ground based

ii. Electric water pumps. Like solar water pumps, they’re surface and submersible options

iii. Diesel generator water pumps. They run on diesel powered engines. They are portable or fixed types. The latter are larger in size

iv. Petrol water pumps. They run on petrol powered engines, and are smaller than diesel water pumps

Small Irrigation Equipment Supplier

Water pump accessories

Accessories that accompany motor powered pumps are; foot valves, clips, suction pipes, adaptors, splicing kits, control boxes, invertors (for DC to AC converstion) cables, cable ties, solar panels (for solar pumps), and a solar panel support structure

Accessories that accompany motor powered pumps are; foot valves, clips, suction pipes, and adaptors

Every irrigation system has a main, and/ or sub-main pipes. Our irrigation pipes are HDPE and PVC. We advice on the right pipe thickness, size and type based on

- Land size; determines pipe size. Large pipes for large acreage. Our pipe sizes range from 16mm to 180mm in diameter

- Irrigation system adopted; any of the 1 to 3 above

- Land ownership system; leased or owned? HDPE for the former, PVC for the latter

These pipes have specific fittings which are; elbows, tees, valve sockets, ball valves, couplings, adaptors,sockets,saddle clamps, and end caps by type and size

Drip irrigation system under installation by Grekkon Limited using PVC pipes as main and sub-main lines

Small Irrigation Equipment Supplier

Installation Service

Our irrigation service team conducts systems installations service in east Africa. We offer advisory services to manage the system well for many years

A client’s irrigation system installation by a company technician

Long Range Sprinkler

Our long range sprinkler models irrigate large acreage of horticulture, fruit, corn, wheat, barley, canola, and potato crops. Every long range sprinkler in Kenya by Grekkon Limited is from 1-1/2” to 2-1/2” inlet diameter size. These sprinklers provide fine rain drop sized watering in the field when operating at optimal capacity

Long range sprinkler specifications

- Material. Aluminum, brass, and steel

- Nozzle sizes. 12mm, 16mm, 18mm, and 20mm

- The diameter of spray. 35M to 40M for the 1-1/2” and 45M to 60M for the 2”

- Discharge volume. 15 cubic to 30 cubic per hour for the 1-1/2” and 20 cubic to 45 cubic per hour for the 2″

Note that the diameter of spray and discharge volume is a factor of the nozzle size and diesel or electric pump capacity (engine/ motor size, pressure rating, and discharge rate)

How much is a long range sprinkler in Kenya?

- 1-1/2” is Kes 55,000

- 2” is Kes 65,000

This cost is inclusive of the steel tripod stand

How to work with long range sprinkler requirements

i. Water availability. It requires 30 cubic per hour as a minimum. If irrigation takes 5 hours per day, then 150 cubic must be available

ii. Pressure. Check your ground elevation, determine your pressure loss in the system and your pipe size. Work backward to determine the water pump type that matches your sprinkler choice. The frictional losses along the pipeline will be taken into consideration too

iii. Crop water requirement. This determines the time spent in irrigation

iv. Land size. This will determine the number of units to run per session

A long range 2″ rain gun sprinkler on display at Grekkon Limited’s ware house in Athi River

Long range sprinkler

FAQs

1. How much does a sprinkler system cost in Kenya?

The cost of a sprinkler system in Kenya is from Kes 55,000 per acre depending on the sprinkler type and number of sprinklers installed

2. What is the distance of a rain gun?

This is from 17M to 50M diameter of spray

3. How much HP motor is required for a rain gun?

A ran gun sprinkler will work with a fossil fuel powered water pump with an engine power from 7.5Hp

4. What pressure is needed for a rain gun?

From 3 bars or 30M lift

5. How to select a long range sprinkler?

Consider the following

- water volume available

- the water pump specifications

- the lift or ground elevation

- the acreage under irrigation

- your budget

6. What are the benefits of a long range sprinkler system?

- it irrigates over a short period of time saving energy

- it is movable

- there are different sizes to choose from

- it covers both small and large acreage

- it is easy to install

- a large volume of water is provided

- it raises the humidity level around the crop

7. What are the disadvantages of a long range sprinkler?

- it consumes copius amounts of water

- it requires a large water pump for energy

- if left operational for a longer than recommeneded period, it causes soil erosion

- it will not work with gravity flow as the pressure is too low

- it is unsuitable for certain crops because they cause flowe rabortion or make them more susceptible to fungal infections when the foliage is left moist

8. How efficient is a rain gun?

It uses half the water volume that flood irrigation would use. However, it uses more than 3 times what would be achieved under drip irrigation

9. What is the diameter of a rain gun sprinkler?

The diameter of a rain gun sprinkler is from 1″ through 2-1/2″

10. How long does a sprinkler system last?

From 20 years under proper care for the metallic types, and just under 5 years for th plastic analogues

11. How effective is rain gun irrigation?

It is carried out for many crops so long as there is sufficient water volume at the source. It is particularly useful for crops that have large spaces in between

12. What is the difference between rain gun and drip irrigation?

- water application. Rain guns apply from the top (overhead), while drip pipes apply from below

- water efficiency. Drip irrigtaion is more water efficient

- cost. drip irrigation systems are more expensive to install

- crop type. drip irrigation will be used for more crop types than rain gun sprinklers

- rain gun sprinklers unlike drip lines will be installed in uneven terrain

- rain gun sprinklers are preferred most under large acreage

13. How many minutes should I run my rain gun?

Depending on the rain gun size, this is from 15 minutes for the large ones, to 35 minutes for the smaller types. Irrigation is done twice a week

14. How do you maintain your sprinkler system?

- ensure that there are no blockages

- clean any debris stuck

- change or repair any loose springs

- limit the number of operators to one 2 persons only

A 2-1/2″ long range rain gun sprinkler at work

Long range sprinkler

Your long range rain gun sprinkler will have a tripod steel support stand. The water delivery pipe is attached to the hollow bottom of the stand. The diameter size of this hollow bottom is the sprinkler’s size

The water drops are fine to use on flowering crops without causing flower abortion. On solanaceous crops such as; tomatoes, potatoes, peppers, irrigate in the morning hours and not in the evening. This allows the moisture to dry off from the leaves, which minimises blight or mildew infection

Before installation, our technical team makes a site visit to make the system layout plan. This is important to ensure that every inch of the farm is covered during irrigation and that there are no dry shadows

These giant sprinklers irrigate over a short period of time, in a large area

Solar Dryers For Coffee In Kenya

Solar dryers for coffee in Kenya by Grekkon Limited improve the drying efficiency of harvested coffee cherry. In Kenya, harvested cherry is largely manually open dried which takes 10 – 14 days depending on the location and the prevailing temperatures. Open coffee drying is done on wooden raised table structures with a wire mesh bed laid out where the coffee cherry is spread thinly. The coffee cherry is dried by direct solar radiation and wind movement

Cost of solar dryers for coffee in Kenya

The overall cost of a solar dryer depends on the size. The average price of a large solar dryer for coffee in Kenya is Kes 1,200/M square

Challenges of open coffee drying

- it is labour intensive. This is needed to turn it over every 45 minutes to 1 hour on the bed to ensure eveness of drying, covering it in the evening or on rainy days with a polythene cover to prevent moisture entry. This increases the cost of coffee erries drying

- quality degradation as a result of moisture entry, dirt, elements of nature, and other contaminants

- it requires lots of space because the beds cannot be designed in a storeyed manner

- none uniformity of drying because it is turned over by hand on the raised drying beds

Open drying of coffee cherries in a coffee factory in western Kenya

The key advantage of open sun drying of coffee is that it is cheap, and has zero CO2 emissions

The coffee is dried from 60% to 10% – 11% moisture level. There are six stages in cofee drying

1) Skin drying. Moisture 55-45%.

2) White Stage drying. Moisture 44-33%.

3) Soft Black stage. Moisture 32-22%.

4) Medium Black Stage. Moisture 21-16%

5) Hard Black Stage. Moisture 15-12%

6) Fully dry coffee and conditioning. 11-10%

Coffee drying is a post-harvest handling process where the coffee quality is preserved instead of improving it. Different temperature limits are allowed for different coffee processing methods. Moisture level are checked to prevent moulding on the drying coffee

Solar dryers for coffee in Kenya by Grekkon Limited provide a low cost, efficient, zero CO2 emissions, and a clean way to dry cofee cherry. The use of solar dryers mitigates against the challenges faced under open sun drying.

How does a solar dryer for coffee work?

1. Air in the dryer in contact with the coffee is heated through solar radiation

2. Moisture in the coffee beans rises and is expelled through a ventilation

The temperature in the coffee solar dryer is on or about double that of the ambient temperature

Benefts of a solar dryer for coffee

- the coffee beans are not tuned over manually to achieve eveness of drying. This cuts out the huge labor cost coffee factories incur during coffee drying. Eveness of drying is well achieved as hot air dries every bean uniformly

- there is no external mositure entry especially from rain. This removes any occurence of moulding or mildew

- coffee dries at half the time or less that it would take under direct sun drying. This reduced drying time saves on operational costs

- there are no external contaminants

The exterior of a solar dryer built in a coffee factory by Grekkon Limited

- the polythene paper cover used has UV block treatment which preserves the quality of the coffee bean. It also has anti-drip attributes, so that dew does not form on it, then drop on the coffee

- space is eficiently used because the drying racks are stacked up over each other, unlike in open sun drying where each coffee cherry must make contact with the sun’s rays to dry

- in areas where coffee theft in factories is rampant, the solar dryer can be locked to prevent entry. This is not possible under open sun drying

- drying goes on even in hazy, cloudy or rainy conditions. Coffee is thus dried anytime of the year, creating drying efficiencies for the coffee factory

Demerits of a dryer for coffee

- it is expensive to isntall

- the polythene cover has to be changed every 3 -4 years when the UV block treatment has worn off

- it is uncomfortable to work in during the day as the internal temperature is high

- where care is not taken, over-drying of coffee may happen, which reduces its quality and its subsequent market price. A moisturemeter should always be used in the drying process to prevent this

- it requires maintainance, such as replacing the UV block treated polythene sheet every 3 years, when the UV block treatment degrades

A coffee solar dryer working principle

A conventional coffee solar dryer can be enhanced with solar module powered extraction, and exhaust fans, which converts it to a hybrid coffee solar dryer. This will further improve on the drying time as moisture is extracted faster. However, due to the large size of the unit, it is an expensive undertaking. It is largely used in smaller fish, herbs, spices,vegetable and fruit solar dryers

How to install solar dryers for coffee

- create raised tables from timber or galvanised steel not more than 1M in width. The length is as much as can be done. These tables can be storeyed upto 3 levels with vertical gaps of 0.75M – 1M between the levels. The horizontal distance from a table to another is 0.5M

- lay a food grade wire mesh over the tables to hold the coffee. A shade net or insect net can be used. The reason a perforated membrane is laid is to allow for free drying air movement on the beans

- construct the galvanised steel framework over these tables to amaximum mid height of 5M

- lay the greenhouse polythene paper over the steel frame

- place an insect net in the air entry and exit points. An insect net prevents entry of insect pests

A 2 level table bed coffee dryer by Grekkon Limited in Kagumoini area, Nyeri county

Grekkon Limited provides training on proper coffee drying in a solar dryer, and also on the maintainance and managemnt of the solar drying unit after installation to coffee societies in Kenya

(more…)

Cost Of Drip Irrigation Per Acre

The cost of drip irrigation per acre in Kenya varies from crop to crop. Grekkon Limited is the top most of all drip irrigation kits suppliers in Kenya. Our drip irrigation system price in Kenya depends on the crop type

For tree crops and hedges, button drippers are installed. In vegetable crops, pre-perforated drip pipes are laid. The emitter spacing on the pre-perforated drip lines is either; 15cm, 20cm, or 30cm. A grower selects according to the vegetable crop type spacing.

We provide our growers a choice of single or double emitter drip irrigation tapes. Double emitter drip lines are helpful in high saline irrigation water locations where salt precipitates form and clog drip emitters. When one emitter is clogged, then the other one continues to irrigate at the same rate. Drip irrigation pipes for sale in Kenya by Grekkon Limited are PVC, and HDPE types

A 3-row drip per bed installation for a vegetable by Grekkon Limited in Ol-Donyo Sabuk area, Machakos county

A button dripper irrigation system on macadamia in Item area, Elgeyo Marakwet county by Grekkon Limited

Cost of Drip Irrigation Per Acre

Determining Factors

- Crop type.It determines the crop spacing. Is it a fruit or vegetable garden? Fruit trees and fruit vines or runners such as melons 🍉 take less drip tape per acre. So they have the least cost. Vegetable crops take more drip lines, and are thus more expensive

- Pipe type. It is a PVC or HDPE mainline, and sub-mainline? The former is more expensive to work with

- Water pressure available. The higher the pressure, the less the number of irrigation blocks. Less irrigation blocks per acre means less fittings and accessories, so it’s less expensive. With low pressure, more irrigation blocks are created, at a higher unit cost

I. An Eighth To One Acre Drip Irrigation Kit Prices

| Crop Type | Drip Lines Per Bed | Acreage | Cost in Kes |

| Watermelon | 1 | 1/8 | 15,000 |

| 1/4 | 25,000 | ||

| 1/2 | 45,000 | ||

| 1 | 85,000 | ||

| Tomato, cabbage, chilies, capsicum, green beans, peas | 2 | 1/8 | 25,000 |

| 1/4 | 40,000 | ||

| 1/2 | 75,000 | ||

| 1 | 140,000 | ||

| Onion, garlic, herbs, spices, strawberry | 1/8 | 27,500 | |

| 3 | 1/4 | 45,000 | |

| 1/2 | 85,000 | ||

| 1 | 160,000 |

II. Fruit Tree Button Drip Kit Irrigation Prices

| Crop Type | Acreage | Cost in Kes |

| Tree Tomato/ Pawpaw/ Passion/ Coffee | 1/8 | 15,000 |

| 1/4 | 25,000 | |

| 1/2 | 45,000 | |

| 1 | 85,000 | |

| Avocado | 1/8 | 15,000 |

| 1/4 | 25,000 | |

| 1/2 | 40,000 | |

| 1 | 70,000 |

FAQS

a. How much does it cost to install a drip irrigation system in Kenya?

The tabulated cost of drip irrigation per acre in Kenya includes the cost of installation by our technicians. We conduct our installations in all of east Africa, for every grower. After installation, our agronomy team provides 4 months of free agronomy training for new farmers.

b. How much does drip irrigation cost per hectare?

The cost of drip irrigation per hectare is 2.5 times the cost provided per acre

c. How many drip lines per acre?

This is determined by the crop type. 3,000M for 1 drip row per bed, 6,000M for 2 drip rows per bed, and 8,000M for 3 drip rows per bed

4. What is the maximum length of a drip irrigation line?

Your 16mm drip irrigation line will run for 25 to 27M under gravity flow, where the head is below 10M. From 10M head, this will go up to 50M

5. How far apart are drip irrigation holes?

Our emitter spacing is; 15cm, 20cm, and 30cm

15cm drip emitter spacing on a 1,00M single emitter drip roll

6. How do I calculate drip irrigation?

- Determine the emitter spacing, for example 15cm

- Divide the drip length by this spacing to determine the number of emitters per roll. In our case, 1,000M divided by 0.15M= 6,667 emitters

- Multiply the emitters by the number of rolls per acre, for example 6 rolls, so 40,000 emitters per acre

- Multiply the emitter flow rate by the total number of emitters to get the amount of water discharged per hour. For example 1.5 litres per hour x 40,000= 60,000 litres per hour

7. Which pipe is best for drip irrigation?

HDPE pipes are the best as main and sub main lines because they have UV treatment. This means that they will be used either as surface or sub-surface pipes

8. Can you run a drip line uphill?

Yes. But the head of the flow must be higher than the vertical height of the slope

9. What pipe size should I use for drip irrigation?

The size of the main or sub main pipe installed is determined by the area under irrigation. The larger it is, the larger the pipes used

10. How do I know how long to run drip irrigation?

This is determined by the existing level of soil moisture. Run it for 20 minutes to 1 hour according to the amount of water needed

11. How do I increase the pressure in my drip irrigation system?

They are several ways to raise the irrigation water pressure in your drip irrigation system

i. Divide the farm into blocks, each of which is irrigated separately. This way, irrigation water is channeled to particular block under high pressure

ii. If it is by gravity flow, then by raising the storage elevation. This will work where raised water tanks are the source of irrigation water

iii. By introducing an external source of pressure, such a s water pump to boost the flow of irrigation water in the system

Pixie Orange Farming And Irrigation

Pixie orange farming and irrigation in Kenya is a high investment, high returns farming venture. Pixies originate from California, USA where they were developed as a cross between oranges and tangerines. They are yellow-orange in colour, sweet and seedless fruits rich in vitamin C. They boost the immune system and increase collagen production which is great for the skin. In this piece, we answer commonly asked questions on pixie orange farming and irrigation by growers in Africa

1.How do you grow pixie oranges in Kenya?

They grow in most soils, but the best are deep (at least 18 inches or 42 cm deep) fertile sandy loams with a pH range of 6.5 – 7.3

Ripe pixie oranges on a tree

2. How do you plant pixie oranges?

The dimensions of the planting holes are 2ft x 2ft x 2ft. This allows for water conservation and deep root penetration as the tree grows. mix the top soil thoroughly with well decomposed manure especially in weak soils

3. What is the spacing for pixies?

Row to row 5M, plant to plant 4M to give an average population of 200 plants per acre. A mature full-sized tree tree is 6M – 9M tall, and equally wide with an extensive root system

A mature well spaced pixie orange crop

4. How long do pixie oranges take to grow out?

Pixie oranges take 2 years to their first fruiting season, but full maturity is between 3 -5 years

4. How many oranges will one tree produce?

The first fruits (30 – 50 fruits) come in the second year, then 250 -300 in the third to fifth years. By the eighth year, the tree bears 500 -600 fruits annually. To produce this commercial quantity all year round, irrigation must be undertaken

5. How many pixie orange trees per acre?

200 trees on average

How To Irrigate Pixie Oranges In Kenya

Pixie oranges require a high amount of water to grow because they are ever green. Under rain fed production, it will be at least 1,000mm of rain annually. However, to produce commercially, irrigation will be done to supplement rain. A tree will have 20 litres at planting, and thereafter, ensure that the soil is consistently moist, but not soggy. The root system must not be allowed to dry out, and neither should there be standing water. Irrigation is at the root zone, away from the trunk

Pixie Orange Farming And Irrigation

Methods

I. Sprinkler Irrigation

Micro sprinklers at the base of the plant are the most efficient or all overhead irrigation methods. Micro sprinklers are low-pressure, low to medium volume irrigation equipment that deliver water directly to the crop root zone. They provide full scale surface irrigation, and localised watering of trees

Micro sprinklers installed by Grekkon Limited in an orchard

II. Button drippers

This is the most water conserving and efficient irrigation system. The water loss to evaporation is less than that of micro-sprinklers, and it requires lower pressure to operate

A button drippers system installed by Grekkon Limited at work in a newly established fruit farm

Irrigation Company In Eldoret

The story of an irrigation company in Eldoret begins five years ago. In 2017, two Kenyan agri-prenuers came together to establish an irrigation systems firm to serve small to medium scale commercial farmers in Kenya. This was by providing tailored professional irrigation systems set up solutions that were within these farmers’ budgets. At the same time, improving the clients’ overall yield, and income from farming. The motivation to focus on this niche was because of the presence of large international irrigation service providers. Their clientele were the large ornamental, cereal and vegetable growers. Smaller growers had to fend for themselves because they were never a priority for these large corporates.

The other objective was to do further by offering expert irrigation, greenhouse, water pumps, and dam lining expertise. This is to small scale to medium scale commercial farmers, who had no professional entity to consult for such. It was through physical site visits to carry out assessments, provide advice, and carry out irrigation project reviews afterwards. And so, Grekkon Limited – Irrigation Hub was born.

The headquarters are Nairobi, Kenya’s capital. In April 2018, Grekkon Limited opened Eldoret irrigation hub along Kapsabet road in Kaburwa area within Eldoret municipality.

In mid-2021, the company opened a sub-branch in Eldoret town central business district. This is to serve farmers picking none bulky items such as irrigation fittings and accessories. The new sub-branch is located in Sugarland plaza, along Oloo street.

The irrigation company in Eldoret serves growers in; Nandi, Usain-Gishu, Bungoma, Trans-Nzoia, West Pokot, Turkana, Elgeyo Marakwet, and Baringo counties. These counties have varying climatic conditions and weather patterns. Those in the south are green with predictable rain patterns, hose in the north are arid and semi-arid locations.

Innovation

Grekkon Limited is the first irrigation systems company in eastern Africa to introduce the rain hose irrigation system. This new product solved many irrigation challenges for commercial vegetable and corn farmers. The company is the market leader in research and commercialization of natural solar dryers. Each unit designed to meet the product or market drying requirements. Today, Grekkon Limited is the largest supplier of natural solar dryers in western Kenya, and the north rift regions.

Team

Grekkon Limited’s resounding success is largely due to its team of field professionals in Nyahururu. They provide engineering, commercial, and technical services. In a first in the market, the company organizes ‘training days’ in various regions of the counties. Here, where growers come to learn of new and existing technologies. This knowledge sharing module has proved effective in addressing basic irrigation challenges that farmers go through. It has created trust in the company’s expertise.

Irrigation Company In Eldoret

The Future

There is a growing number of medium scale farmers living in the cities, but farming in the upcountry. The need to create a web-based irrigation monitoring system is more pronounced than ever. Grekkon Limited’s IT team is developing a gadget responsive tool. It will enable farmers to irrigate and fertilise (through fertigation) their farms remotely. It also woks s a moisture monitoring tool to alert growers when crop moisture levels fall below normal levels.