Omer Prime Trader: Your Gateway to Crypto Trading

In a world where digital currencies are revolutionizing the financial landscape, Omer Prime Trader stands out as a leading trading platform for cryptocurrencies. It offers a unique blend of advanced features, user-friendly interface, and global reach, making it an ideal choice for both seasoned traders and beginners.

Omer Prime Trader is designed to cater to the needs of a diverse range of traders, offering multilingual support in English, Spanish, French, German, Italian, and Arabic. This is in line with its mission to serve the global trading community across all supported regions, which include Europe, the Americas, Middle East & North Africa, Asia-Pacific, and African regions including French territories.

The platforms unique selling proposition lies in its ability to simplify the complex world of crypto trading. It provides a seamless interface that allows traders to buy, sell, and manage their cryptocurrency portfolio effortlessly. Whether you are trading in Bitcoin, Ethereum, or any other digital currency, Omer Prime Trader ensures that you have all the tools and resources you need at your fingertips.

But the benefits of Omer Prime Trader go beyond its user-friendly interface. It also provides a wealth of educational resources that help traders understand the nuances of cryptocurrency trading. From market trends to investment strategies, Omer Prime Trader empowers its users with the knowledge they need to make informed trading decisions.

Moreover, Omer Prime Trader is committed to ensuring the safety and security of its users investments. It employs advanced security measures to protect users funds and personal information. This focus on security, coupled with its commitment to transparency, makes Omer Prime Trader a trustworthy platform for trading cryptocurrencies.

As a testament to its global reach, Omer Prime Trader supports a wide range of countries including France, Germany, Italy, Spain in Europe; Canada, Argentina, Colombia, Puerto Rico, and Jamaica in the Americas; Lebanon, Jordan, Libya, Egypt in the Middle East & North Africa; Pakistan, Sri Lanka in the Asia-Pacific; and Nigeria, Kenya, Namibia in Africa. It also includes French territories like Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, and French Polynesia.

In conclusion, Omer Prime Trader is more than just a trading platform; it is a comprehensive solution for all your cryptocurrency trading needs. With its wide range of features, global reach, and commitment to user satisfaction, Omer Prime Trader is indeed a prime choice for crypto traders around the world.

Unleashing the Potential of Cryptocurrency Trading with Arbah Capital

As the cryptocurrency market continues to evolve and expand, there is a growing need for robust and reliable trading platforms that can cater to both novice and seasoned traders. One such platform that has been making waves in the industry is Arbah Capital. This article aims to shed light on the unique features and offerings of Arbah Capital that are revolutionizing the crypto trading experience.

A Global Trading Platform with Multilingual Support

One of the distinguishing features of Arbah Capital is its global reach. The trading platform provides services across Europe, including France, Germany, Italy, and Spain, and extends its support to the Americas, with a presence in Canada, Argentina, Colombia, Puerto Rico, and Jamaica. It is also operational in the Middle East and North Africa, covering countries like Lebanon, Jordan, Libya, and Egypt. This global footprint extends to the Asia-Pacific region, serving countries like Pakistan and Sri Lanka, and the African nations of Nigeria, Kenya, and Namibia. Furthermore, Arbah Capital also covers French territories like Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, and French Polynesia.

Arbah Capital understands the importance of language in providing a seamless trading experience. To cater to its diverse user base, the platform offers multilingual support in English, Spanish, French, German, Italian, and Arabic.

Revolutionizing Crypto Trading with Arbah Capital

Arbah Capital is not just a platform; its an ecosystem that empowers traders to make informed decisions by providing them with the necessary tools and resources. The platform comes equipped with an intuitive interface and a comprehensive set of features that make trading a breeze.

At its core, Arbah Capital aims to simplify the complex world of crypto trading. It provides real-time market data, insights, and analytics, helping traders make informed decisions. Moreover, the platform supports a wide array of cryptocurrencies, thereby allowing traders to diversify their portfolio.

Secure Trading Environment

Security is a paramount concern in the world of crypto trading. Arbah Capital is committed to providing a secure trading environment for its users. It employs state-of-the-art security measures to protect user data and funds. Furthermore, the platform complies with all the necessary regulations to ensure a safe and reliable trading experience.

Conclusion

In a nutshell, Arbah Capital is a comprehensive trading platform that is designed to cater to the needs of a diverse range of traders. With its global presence, multilingual support, user-friendly interface, and robust security measures, Arbah Capital is truly revolutionizing the crypto trading experience. Whether youre a novice trader trying to make your way in the crypto world or a seasoned trader looking for a reliable platform, Arbah Capital is certainly worth considering.

Shade Nets In Kenya

As the top among all shade net suppliers in Kenya, Grekkon Limited’s shade nets in Kenya are of different types and color. We have all types of shade nets for agriculture, for the production of both food, and none food crops. The cost price of a shade net roll is from Kes 12,500. Below, we answer commonly asked questions

1. What are shade nets?

They are HDPE, UV treated woven or knitted netting material that regulate the amount of light and heat from the sun, air and moisture. Shade nets reduce the temperature delta (difference between day and night temperatures), thereby avoiding a sudden temperature variation, so that plants don’t suffer from thermal shock A good degree of beneficial moisture is trapped between the ground and the net. They are water permeable so that rain water, and irrigation water will reach the crop and keep it hydrated

A knitted green shade net roll

A knitted black shade net roll

2. What are shade nets used for?

- In the nursery to protect seedlings from direct radiation, and harden seedlings

- In orchards and farms to protect crops from intense sunlight as well as bird and insect pests

- Shade net fencing. On a fence to block excessive wind on the crop, and to reduce the farm’s view from outside

- To cover water reservoirs or water tanks so as to reduce water loss by evaporation

- In livestock production to protect them against extreme heat

3. How much do shade nets cost in Kenya?

Tabulated below are our shade net prices in Kenya are per meters squared, by type

| % Shade | Cost per M Sq In Kes |

| 30% | 70 |

| 55% | 75 |

| 75% | 100 |

| 90% | 170 |

Grekkon Limited’s shade nets are available as 50M x 4M rolls in all our branches country wide

4. What is the cost of shade net per acre?

Our shade nets for sale in Kenya by per acre are measured as 4,100M sq

| % Shade | Cost per Acre In Kes |

| 30% | 295,200 |

| 55% | 352,600 |

| 75% | 410,000 |

| 90% | 697,000 |

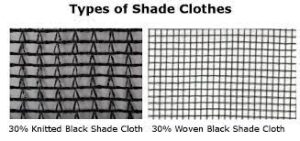

5. What are the types of shade nets?

By material

- Woven shade nets. They are made from polypropylene, are heavier and allow heat build up. They withstand the most extreme exposure to the sun, and have minimum shrinkage. Woven shade nets are for shading of plants, pet kennels, windscreens, patios and for privacy. Woven shade nets are 30% heavier than knitted shade nets, and are difficult to install

- Knitted shade nets. They are made up lightweight polyethylene. They have an open lock-stitch design that resists wind damage, and reduces heat build up in the net. The level of shrinkage is 2% to 3%. Knitted shade nets have better longevity in agricultural use as they resist agro-chemicals and detergents. They are preferred for shade houses, and greenhouses.

Grekkon Limited’s shade nets are all knitted with monofilament fabric which is durable due to he thicker thread. A thicker thread has a longer process of photo oxidation as compared to a thinner thread, hence the longer lifespan

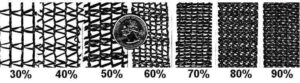

By % shade

- 90% shade nets are appropriate for crop nurseries located in low altitude or extremely hot locations

- 75% shade nets are preferred for nurseries in high to mid altitude locations that are also hot. They are also used in the hardening stage of seedlings in hot low altitudes. This will grow ferns, orchids and succulents

- 55% shade nets are for hardening of nursery crops, or for growing plants in very hot locations for crops that are sensitive to intense sunlight. Good for growing cabbage, geraniums, lettuce, foliage plants, cuttings, orchids and most potted plants

- 30% shade nets are for growing crops that need just a little bit of shading, yet lots of light for photosynthesis. Great for growing heat tolerant plants like tomato, pepper, roses, strawberry, cucumber and squash

By color

- Black

- Green

The color choice does not affect the performance for these two. Both allow all light wavelengths go through. However, brightly colored shade nets like white and aluminum reflect the sun’s heat creating a cooling effect

6. How do shade nets work?

They absorb or reflect the sun’s heat. They act as filters by depriving the plants of excess sunlight

Shade Nets In Kenya

How To Select The Right Shade Net

- Crop type. Some crops require more shade than others

- Stage of growth. Seedlings will be more shaded than mature crops

- Farming method. A shade net on a greenhouse will be lighter than that in the open field for the same crop

- Season. Denser nets will go with hotter seasons

- Location. Hot low altitude locations will have denser nets than higher altitude cooler places

- Usage. The wind break net, the water reservoir cover net, the greenhouse cover net, and the open field net will differ

A green shade net installed as a wind break

Our shade nets are green or black in color. The color has no bearing on the net effectiveness, but is rather for aesthetic reasons. Shade nets are supported by steel, or wooden frames for shade houses

Mulching Paper Price In Kenya

Grekkon Limited’s low density polyethylene (LDPE) mulching paper price in Kenya is a factor of plastic mulch paper thickness given in microns. We supply silver on black mulch paper in different thicknesses to high value crop growers in Africa.

Our plastic mulch paper is UV treated to prevent rapid solar degradation when in use. Our available thicknesses are; 30 micron, 60 micron and 70 micron. Our mulch paper is in rolls of 1,000M x 1.6M. We cut it longitudinally from this roll according to a grower’s need. The company also installs, and trains first time growers on how to make planting holes on plastic mulch paper

Does Water Go Through Plastic Mulch?

Overhead water sources such as rain or sprinkler irrigation won’t penetrate the plastic to get to the soil

Can You Use Plastic Mulch Without Drip Irrigation?

Yes. Irrigation is done by pouring water in the holes where the plants are. This is a tedious and time consuming process

Advantages of Plastic Mulch

i. Early start for crops. Plants take off with vigor because they have sufficient moisture retained within their root zones. Again the warmth retained in the soil hastens crop growth.

ii. Reduces water wastage. Water loss resulting from evaporation is largely reduced which saves on daily irrigation operational costs.

iii. Less upkeep. Mulch paper stifles weeds which saves weeding operational costs, removes competition for nutrients and light against the crop by weeds.

iv. Better crop quality. Mulched crops have better yield quality as a result of less disease and pest attack, and a more vigorous growth.

Strawberry production in a tunnel house using silver on black mulch paper by Grekkon Limited to cover the ground. Location: Jua Kali area, Laikipia county

Disadvantages

- It is not biodegradable

- It is more expensive to use than organic waste mulch

- Irrigation is limited to drip irrigation

i. What is purpose of mulching paper?

- To retain soil moisture by preventing moisture loss through evaporation

- To prevent weed growth

Mulching accelerates crop growth due to mositure retention, and better feeding 9reduced competition for food and light with weeds). This cuts the time the crop remains in the field, which reduces operational costs. Better feeding equals better yield, and higher income

Silver on black mulch paper in a herbs cropping field at Heni area, Nyandarua county

The silver coloured part faces up to reflect excess heat, while the black part faces down to retain warmth

The choice of mulch paper thickness depends on;

- Crop growing duration. For short term, single or 2 season crops, a grower will pick the 30 micron paper which will last as long. For long-term crops such as bi-annuals and perennials, the farmer will install the thickest gauge

- Budget. The thicker it is, the costlier the paper

ii.How much mulching paper do I need for 1 acre?

Assume that a nacre measures 63.3M x 63.3M, with 1M wide beds, with paths of 0.5M in between. This gives a total of 42 beds, each running 63M in length. To get the total amount of mulching paper, multiply the number of beds, by the bed length and the width of the mulching paper as below;

42beds x 63.3M x 1.6M = 4,234M sq

iii. What is the cost of mulching per acre?

The cost of your mulching paper cost per acre will be 4,234M sq by the cost per meter square of your chosen thickness. These are tabulated below

Mulching paper price in Kenya

| Mulch Paper Thickness | Price in Kes |

| 30 micron | 20/ M SQ |

| 60 micron | 35/M SQ |

| 70 micron | 45/ M SQ |

A silver on black mulching paper roll. Smaller mulching paper needs are cut from this as per the grower’s specifications

iv. Which crops need mulching?

This is for high value crops. In Kenya, examples are;

- export herbs and spices

- strawberry

- apples

- greenhouse tomato, cucumber, capsicums, and chilies

v. What are the 3 benefits of mulch?

- ensures soil moisture retention

- cuts down weeding costs

- the crops grow faster and more uniformly

vi. What is the disadvantage of mulching paper?

- it is expensive

- it is an environmental hazard after use because it has to be burned

- it does not allow in rain water, so the crop is fully reliant on irrigation

vii. Which is the best mulching paper?

The thicker it is, the longer it lasts. However, budget considerations are made based on how long the cropping season is, and the need to mulch in the next season

viii. What are the 2 types of mulch?

- organic mulch. This is from crop waste and grass straw

- inorganic mulch. This is made from plastic (LDPE)

Organic mulch from grass straw in a strawberry field

ix. How long does plastic mulch last?

Depending on the thickness, it is as follows

30 microns; 2-3 cropping seasons

60 micron; 4-5 cropping seasons

70 micron; > 6 cropping seasons

x. How do you install mulching paper?

- prepare the land to a fine tilth

- make raised beds, and remove any large soil clods. These will cause air trapping in the paper

- cover the top and sides of the bed with the mulching paper

- perforate holes on the plastic mulch where the crop will be planted

xi. When should you use mulching paper?

- When growing high value crops such as; strawberry, coloured bell peppers, greenhouse tomato, herbs and spices

- If there is insufficient or expensive irrigation water. Mulching will conserve moisture in the soil, reducing irrigation water costs dramatically

- If there is a high prevalence of stubborn weeds. Mulc paper will suppress their growth

Herbs (chives) growing in a greenhouse under plastic mulch paper

xii. What is plastic mulchpaper made of?

Polyethylene

xiii. What is an alternative to mulching paper?

Organic mulch. This is from straw, leaves, shredded bark, shredded newspaper, hay, sawdust or wood chips, cardboard, manure, or other organic matter

xiv. How thick is mulching paper?

Grekkon Limited supplies 30 microns, 60 microns, 70 microns, and 80 microns plastic mulch paper

Our mulching paper price in Kenya is similar across all our branches in Athi River, Nairobi, Kisumu, Eldoret, Nyeri, and Nyahururu

Exploring the World of Cryptocurrency with Crypto Noan

As the cryptocurrency market continues to evolve, various platforms are emerging to facilitate the trading of these digital assets. Among these is Crypto Noan, a globally recognized platform designed to accommodate the needs of cryptocurrency traders across multiple regions, including Europe, the Americas, Middle East & North Africa, Asia-Pacific, and African regions, including French territories.

Crypto Noan is not just a platform; it is an innovative solution that simplifies the process of trading cryptocurrency. It provides a unique experience, allowing traders to navigate the dynamic world of cryptocurrency with ease, efficiency, and confidence.

The platform supports a variety of languages, including English, Spanish, French, German, Italian, and Arabic. This multilingual support ensures that traders from all over the world can utilize the platform with ease, further enhancing the user experience and broadening the platforms reach.

The Crypto Noan Difference

What sets Crypto Noan apart from other trading platforms is its commitment to user-friendliness and innovation. The platform is designed to be intuitive and easy to navigate, even for beginners. It provides a seamless trading experience, allowing users to monitor their investments and make informed decisions based on real-time market trends.

Moreover, Crypto Noan is not just a trading platform, but a comprehensive solution for cryptocurrency enthusiasts. It offers a range of features and tools that help users make the most of their trading experience. These include advanced charting tools, real-time market updates, and a secure and reliable trading environment.

Crypto Noans Global Reach

Crypto Noans commitment to fostering a global trading community is evident in the wide range of regions it supports. It caters to users from various parts of Europe (France, Germany, Italy, Spain), the Americas (Canada, Argentina, Colombia, Puerto Rico, Jamaica), Middle East & North Africa (Lebanon, Jordan, Libya, Egypt), Asia-Pacific (Pakistan, Sri Lanka), and African regions (Nigeria, Kenya, Namibia), including French territories (Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, French Polynesia).

With its multilingual support, Crypto Noan ensures that language is not a barrier to trading. Its available in English, Spanish, French, German, Italian, and Arabic to serve the global trading community across all supported regions.

Conclusion

In a world where cryptocurrency trading continues to gain momentum, platforms like Crypto Noan are pivotal in facilitating seamless trading experiences. Crypto Noans global reach, multilingual support, and innovative features make it a go-to platform for both novice and experienced traders alike.

Whether youre a seasoned trader or a beginner looking to dip your toes into the world of cryptocurrency, Crypto Noan offers a reliable, user-friendly platform to help you navigate this exciting market.

Unlock the World of Crypto Trading with Grokx Finance

As we continue to navigate the fascinating world of cryptocurrency, more and more platforms are emerging to support this modern form of trading. Among the front-runners is Grokx finance, a trading platform designed for crypto enthusiasts across the globe.

Grokx finance is a versatile platform that aims to make cryptocurrency trading accessible and efficient. It boasts a user-friendly interface and advanced features that cater to both beginners and seasoned traders. This platform is committed to delivering a seamless trading experience, complemented by top-notch security measures to ensure the safety of users investments and personal information.

One of the key highlights of Grokx finance is its global reach. The platform supports a multitude of countries across different regions, including Europe (France, Germany, Italy, Spain), Americas (Canada, Argentina, Colombia, Puerto Rico, Jamaica), Middle East & North Africa (Lebanon, Jordan, Libya, Egypt), Asia-Pacific (Pakistan, Sri Lanka), and African regions (Nigeria, Kenya, Namibia). Furthermore, it extends its services to several French territories, such as Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, and French Polynesia. This wide coverage makes it a go-to trading platform for crypto traders worldwide.

Recognizing the diversity of its user base, Grokx finance also offers multilingual support. The platform is available in six major languages: English, Spanish, French, German, Italian, and Arabic. This feature is a testament to Grokx finances commitment to serve its global trading community and ensure that language is not a barrier to trading.

The platform also shines in its provision of a wide range of cryptocurrencies for trading. Whether youre looking to trade Bitcoin, Ethereum, or other altcoins, Grokx finance has got you covered. With its real-time market data and advanced analytics, users can make informed decisions to maximize their profits.

Another impressive aspect of Grokx finance is the provision of educational resources. Understanding that cryptocurrency trading can be complex, especially for newcomers, the platform provides a wealth of information aimed at empowering users with knowledge. This helps traders to understand the market better and make more strategic decisions.

At Grokx finance, customer service is a top priority. The platform has a dedicated support team that is ready to assist users with any issues or queries. This commitment to customer satisfaction sets Grokx finance apart from many other trading platforms.

Overall, Grokx finance offers a comprehensive solution for cryptocurrency trading, making it a preferred choice for traders across the globe. Its user-friendly interface, global reach, multilingual support, wide range of cryptocurrencies, educational resources, and dedicated customer service make it a reliable platform for both novice and experienced traders. Whether youre new to crypto trading or looking to enhance your trading experience, Grokx finance is worth exploring.

In a world that is becoming increasingly digital, platforms like Grokx finance play a crucial role in promoting financial inclusion and innovation. By providing a secure and efficient platform for cryptocurrency trading, Grokx finance is not just facilitating transactions but also contributing to the evolution of the global financial landscape.

TanjaTrades: Streamlining Cryptocurrency Trading for a Global Community

The world of cryptocurrency trading can be daunting, particularly for newcomers. However, platforms like TanjaTrades are making the process more accessible and efficient for all. TanjaTrades is a pioneering trading platform that brings together the worlds of digital currency trading and innovative technology.

With operations across Europe, the Americas, the Middle East & North Africa, Asia-Pacific, and Africa, TanjaTrades has a truly global reach. It supports trading in countries as diverse as France, Canada, Lebanon, Pakistan, and Nigeria, as well as French territories such as Guadeloupe and New Caledonia. This international focus has made it a go-to platform for cryptocurrency traders around the globe.

One of the standout features of TanjaTrades is its multilingual support. The platform is available in English, Spanish, French, German, Italian, and Arabic. This means that no matter where you are in the world, or what language you speak, you can take full advantage of TanjaTrades cutting-edge trading features.

At its core, TanjaTrades is a platform that makes cryptocurrency trading simple, intuitive, and profitable. It offers a range of tools and resources to help users make informed decisions. The platform uses advanced algorithms and artificial intelligence to track the markets and develop individual trading strategies.

Unlike many other trading platforms, TanjaTrades operates continuously, constantly monitoring the markets and adjusting strategies as needed. This ensures that users never miss a profitable trading opportunity. The platforms intuitive design also makes it easy for beginners to get started, while offering the advanced tools that professional traders need.

Security is another key priority for TanjaTrades. The platform uses state-of-the-art encryption and security protocols to ensure that your data and funds are safe. Plus, with its robust customer support, users can get help and answers to their questions at any time.

But what truly sets TanjaTrades apart is its commitment to transparency and fairness. The platform has no hidden fees or charges, and it offers a clear, straightforward pricing model. This makes it easy for traders to understand exactly what theyre paying for, and ensures they can focus on what really matters – making successful trades.

With its global reach, advanced technology, and commitment to transparency, TanjaTrades is setting a new standard for cryptocurrency trading. Whether youre a seasoned trader or just getting started, TanjaTrades offers a user-friendly platform that can help you navigate the exciting world of digital currency.

In conclusion, TanjaTrades is more than just another cryptocurrency trading platform. Its a global community, a hub of innovation, and a tool for financial empowerment. As the world of digital currency continues to evolve, TanjaTrades is leading the way, making cryptocurrency trading accessible and profitable for all.

ArmourWallet: Your Global Trading Platform for Cryptocurrency

Stepping into the world of cryptocurrency trading can be daunting. With countless platforms available, finding a reliable and user-friendly platform is paramount. Introducing ArmourWallet, an innovative trading platform designed to serve both beginners and seasoned traders in the exciting and ever-evolving world of cryptocurrency.

ArmourWallet is a global trading platform that supports a wide range of countries. Whether youre in Europe (France, Germany, Italy, Spain), the Americas (Canada, Argentina, Colombia, Puerto Rico, Jamaica), Middle East & North Africa (Lebanon, Jordan, Libya, Egypt), Asia-Pacific (Pakistan, Sri Lanka), African regions (Nigeria, Kenya, Namibia), or French territories (Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, French Polynesia), ArmourWallet has got you covered.

Understanding the need for a multilingual platform to serve its global trading community, ArmourWallet is available in English, Spanish, French, German, Italian, and Arabic. This ensures that users across all supported regions can navigate the platform with ease and take control of their trading strategies without language being a barrier.

At its core, ArmourWallet is built on the principles of security, accessibility, and user satisfaction. It employs advanced algorithms and artificial intelligence to track market trends and execute trades with precision. This ensures users can make the most of their trading experience, always staying one step ahead of the market.

For beginners, ArmourWallet serves as a comprehensive guide to the world of cryptocurrency trading. Its user-friendly interface coupled with detailed analytics helps users understand the market better and make informed trading decisions. For seasoned traders, ArmourWallet offers a range of tools and features to craft and execute complex trading strategies with ease.

Further setting ArmourWallet apart from other trading platforms is its continued dedication to user security. All transactions on the platform are protected by robust encryption protocols, ensuring that your funds and personal information remain secure at all times. This commitment to security is matched by ArmourWallets commitment to transparency, with all trading activities on the platform being recorded and readily available for user review.

Finally, ArmourWallet prides itself on its responsive customer support. Should users encounter any issues or have any questions, the ArmourWallet team is always ready to assist. This emphasis on customer satisfaction, coupled with its advanced trading features and global accessibility, make ArmourWallet a top choice for cryptocurrency trading.

In conclusion, whether youre a beginner stepping into the world of cryptocurrency or a seasoned trader looking for a reliable and feature-rich platform, ArmourWallet is designed to meet your needs. Its global reach, multilingual support, advanced trading features, and commitment to security make it a trusted choice for cryptocurrency traders across the world.

The Future of Cryptocurrency Trading: Exploring the Crypton App

As the world of cryptocurrency continues to expand at an unprecedented rate, the need for intuitive, secure, and efficient trading platforms becomes more crucial than ever. Among the myriad of platforms available, the Crypton App stands out as a comprehensive solution for traders across the globe.

The Crypton App is an innovative trading platform that caters to a diverse user base, from novices getting their start in crypto trading to experienced traders looking for advanced tools and analytics. But what sets Crypton App apart from its competitors is its extensive global reach and multilingual support.

Traders from a wide array of regions can take advantage of the platform, including Europe (France, Germany, Italy, Spain), the Americas (Canada, Argentina, Colombia, Puerto Rico, Jamaica), Middle East & North Africa (Lebanon, Jordan, Libya, Egypt), Asia-Pacific (Pakistan, Sri Lanka), and African regions (Nigeria, Kenya, Namibia), along with French territories (Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, French Polynesia). This broad geographical support underscores Crypton Apps commitment to creating a truly global trading community.

The platform also caters to non-English speakers, offering multilingual support in English, Spanish, French, German, Italian, and Arabic. This feature reinforces the platforms accessibility and inclusivity, ensuring traders of different linguistic backgrounds can navigate the platform with ease.

But the Crypton App isn’t just about accessibility; it’s also about providing a superior trading experience. The platform harnesses the power of blockchain technology to offer secure, transparent, and efficient trading. Traders can track their transactions in real-time, manage their portfolio easily, and enjoy seamless deposit and withdrawal processes. The platforms user-friendly interface also simplifies the otherwise complex world of cryptocurrency trading, making it a go-to choice for beginners.

Moreover, the Crypton App is designed with the future of trading in mind. Recognizing the growing trend towards mobile trading, the platform is optimized for use on both desktop and mobile devices, allowing traders to manage their investments anytime, anywhere. It’s a feature that not only caters to the busy, on-the-go lifestyle of modern traders but also the rising demand for mobile-friendly trading platforms.

In conclusion, the Crypton App offers a winning combination of wide geographical support, multilingual assistance, intuitive user interface, and advanced trading tools. By focusing on user experience and accessibility, the platform is ushering in a new era in cryptocurrency trading, one that is inclusive, efficient, and forward-thinking. Whether you’re a novice trader or a seasoned investor, the Crypton App is a trading platform that merits consideration.

As the world of cryptocurrency continues to evolve, the Crypton App is poised to evolve along with it, continually adapting to the needs of traders and the demands of the market. It’s a platform designed for the future of trading, and that future looks bright indeed.

Exploring Arbitpad: Your Multilingual Crypto Trading Platform

Investing in crypto has never been easier with the rise of user-friendly platforms like Arbitpad. As an international crypto trading platform, Arbitpad is designed to accommodate both seasoned investors and cryptocurrency novices. With its robust features and global reach, Arbitpad is poised to revolutionize the way people trade crypto.

Arbitpad is available across a wide range of territories including in Europe, the Americas, the Middle East & North Africa, Asia-Pacific, and African regions. This includes countries such as France, Germany, Italy, Spain, Canada, Argentina, Colombia, Puerto Rico, Jamaica, Lebanon, Jordan, Libya, Egypt, Pakistan, Sri Lanka, Nigeria, Kenya, Namibia and even French territories such as Guadeloupe, Martinique, French Guiana, Réunion, New Caledonia, French Polynesia. This vast geographical coverage opens up opportunities for traders from various parts of the world to participate in the global crypto market.

One of the platforms greatest strengths is its multilingual support, offering services in English, Spanish, French, German, Italian, and Arabic. This not only serves their diverse global trading community but also breaks down language barriers, making it easier for traders to navigate the platform, understand strategies, and make informed decisions.

The platform has a user-friendly interface that simplifies the trading process. It provides real-time data and insights, allowing traders to make quick decisions in the fast-paced crypto market. Traders can also customize their strategies based on their risk tolerance and investment goals.

Security is a top priority for Arbitpad. The platform uses advanced security measures to protect users funds and personal information. It also provides educational resources to help users understand the risks associated with crypto trading and how to mitigate them.

Arbitpad also offers a demo feature, allowing new users to practice their trading strategies without risking real money. This feature is particularly useful for beginners who are still getting to grips with crypto trading. It helps users learn the ropes, understand market trends, and develop effective trading strategies before they start trading with real money.

Despite its advanced features, Arbitpad is designed to be accessible to all. It doesnt require a large initial investment, making it easier for beginners to get started. The platform also provides comprehensive customer support to assist users with any issues or questions they may have.

In conclusion, Arbitpad is a versatile and accessible platform that caters to the needs of a diverse range of traders. Its expansive geographical coverage, multilingual support, user-friendly interface, and robust security measures make it a reliable platform for crypto trading. Whether youre a seasoned trader or a beginner, https://arbitpad.com/ provides a seamless and secure trading experience.