Types Of Dam Liners

As a dam liner company, Grekkon Limited supplies and installs 3 types of dam liners in Kenya by thickness, and 2 types of dam liners by material. In this article, we answer many water harvesting using dam liners questions posed to us by growers

1. What type of dam liner is best?

1.1. Types of dam liners in Kenya – by material

High density polyethylene (HDPE) dam liners

This is what we supply and install most. This is because it is thin and lightweight which makes it easy to carry. They are tough with high tensile strength, hard to puncture, and stiff, which makes them less prone to sudden length tears. However, this stiffness makes welding more difficult. HDPE dam liners have the best UV resistance, and are safe for the environment because they do not emit chemicals. Their disadvantage is that they’re more difficult to repair when perforated. Our HDPE dam liners are in rolls from which we cut and tailor weld it to a water pan’s specifications

A HDPE dam liner installed by Grekkon Limited in Vihiga county, Kenya

Polyvinyl chloride (PVC) dam liners

We supply and install these but at a lessor scale. PVC dam liners are highly flexible, impermeable and tough. They are heavier than HDPE dam liners, but easier to weld as the material joins together more easily. They have the best resistance to chemicals and acids and so they are not easily corroded. This makes them the most suitable for land fills and chemical containment sites. Our PVC dam liners are factory fabricated panels that eases installation. The downside with PVC dam liners is environmental safety because they release chemicals as the PVC material degrades. This in the long-term is toxic to fish

A PVC dam liner installed by Grekkon Limited in a water pan in Kibwezi, Kenya

Low density polyethylene (LLDPE) dam liners

They are made from the same plastic as HDPE dam liners, and so share similarities. Being less dense than their HDPE cousins, they are softer, more flexible and more pliable. Being softer makes them less susceptible to stress cracking. High flexibility allows for easier under installation, and molding them around corners, nooks and crannies. Pliability means they conform best to rough terrain with little wrinkles

An LLDPE liner in a large water pan

1.2. Types of dam liners in Kenya – by thickness

- 0.5mm / 500 microns. This is for smooth surfaces and to hold low water volume (5,000 cubic liters and below)

- 0.75mm / 750 microns and 0.8mm / 800 microns. Works well in rough surfaces with few stones or murram. It will hold medium water capacity

- 1mm / 1,000 microns. Best for stony or rocky surfaces, and high capacity

- 1.5mm / 1,500 microns. Works on surfaces that the 1mm will not, and holds ultra high water volumes

2. Which is better: PVC or HDPE dam liner?

HDPE is better because it has greater tensile strength, and does not contaminate the environment

3. What is a good thickness for a dam liner?

The choice of thickness is determined by the surface and water volume. For instance, a 0.5mm dam liner is more appropriate for a concrete water tank holding 100 cubic litres than a 1mm dam liner

4. What are the 2 main types of dam liners?

HDPE and PVC dam liners are the most common dam liners in Kenya

5. How long does a dam liner last?

This depends on the thickness, material type and use. As a guideline though, 0.5mm thick dam liners last to 15 years, 0.75mm to 25 years, and 1mm to 36 years

6. Can I put a new dam liner over an old one?

The simple answer is yes, but remove any liquid, and solid debris on the old liner’s surface. Note that once the new one is placed, you cannot shift the old liner without affecting the new one. The new dam liner is not joined to the old dam liner in any way

7. How often do dam liners need to be replaced?

So long as the dam liner is functioning well, it is unnecessary to remove it. There is no replacement timeline

8. What is the best liner for a large water pan?

Large is relative. But for any water reservoir holding beyond 5,000 cubic litres, we recommend the 0.75mm or the 1mm thick dam liners

9. How do you hold a dam liner in a water pan?

There are 2 ways.

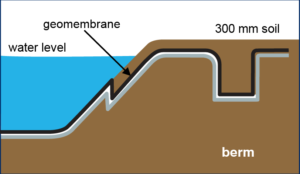

9.1. Trenching

This is where a 2 feet deep by 1 foot wide trench is excavated all round the circumference of the water reservoir. This trench is 0.75M to 1M from the edge of the water pan. The dam liner is tucked in here then covered with soil, gravel or rocks/ stones

The edges of a newly installed HDPE dam liner in a water pan tucked in a trench and covered with soil

9.2. Sand bags

Bags filled with soil, sand or gravel are laid on top of the dam liner edges to anchor it in place

The different types of dam liners does not affect the holding method

10. Can you join 2 dam liners together?

Yes. Pieces of dam liner welded together make a continuous sheet

11. Can you glue 2 dam liners together?

The best way to join dam liners is by welding because it is permanent

12. Can you cut a dam liner?

Yes. We cut and weld together dam liner sheets from large rolls to tailor it to the water pan’s dimensions

13. Can you put gravel on top of a dam liner?

Yes you can especially if it is for support on the edges

What to consider when choosing a dam liner

- The surface texture. Install a thicker liner for rougher surfaces

- Water volume. The larger it is, the thicker the dam liner

- Purpose. If it will hold chemicals or acids, then the PVC dam liner is best because it is the most resistant

Related Posts

Pond Liner Calculator

In this pond liner calculator article, we answer the following frequently asked questions 1. How is a dam liner calculated? The...

Dam Liner Company In Kenya

Grekkon Limited is the foremost dam liner company in Kenya. From material selection, to welding and installation, our professional teams...